Research was conducted on greenhouse gas emissions and the economics of five different options for communities to manage food waste streams — including codigestion and composting. Part III

David L. Parry

BioCycle June 2013, Vol. 54, No. 6, p. 36

How food waste is managed in a community has an impact on water demand and wastewater treatment, energy demand and recovery, transportation, carbon footprint and the people that generate and handle the food waste. The Water Environment Research Foundation (WERF) hired CDM Smith to evaluate and compare the economic and environmental impacts of food waste management methods. For more information on this study, see the published document: Sustainable Food Waste Evaluation (WERF OWSO5R07e). This peer reviewed WERF evaluation was funded by InSinkErator.

The research quantified economic and environmental impacts of five different food waste management methods:

• Landfilling: Curbside collection of commingled food waste with other residential municipal solid waste (MSW) and disposal in a landfill.

• Composting: Curbside collection of source separated food waste with green waste and beneficial use in a large-scale composting facility.

• Food Waste Disposer: Disposal of food waste in a residential food waste disposer, with transportation via the existing sewer infrastructure to the water reclamation facility (WRF) operating with anaerobic digestion.

• Direct Anaerobic Digestion: Curbside collection of source separated food waste, transportation to the WRF and beneficial use in the treatment plant anaerobic digesters.

• Mixed Materials Recovery Facility (MRF): Curbside collection of food waste and MSW. Separation of food waste in a MRF and transportation of the separated food waste to an anaerobic digester at a WRF.

Analytical Methodology

Each food waste management method was developed assuming energy efficient practices. For example, the WRF was assumed to have anaerobic digestion and combined heat and power (CHP). The landfill was assumed to collect the landfill gas and fuel an engine-driven generator. The assumptions common to all food waste management methods are as follows:

• Food waste production was based on a city of 100,000 people producing 3,930 tons/year.

• The chemical composition of the dry fraction of food waste was approximated by C21.5H34.2O12.7N1.

• Food waste characteristics were assumed to be: 69 percent water; 82 percent biodegradable; Density: 31 lb/ft3; 1,870 ton/yr COD (chemical oxygen demand); 1,530 tons/yr biodegradable COD; 1,220 ton/yr total solids.

• Cost analysis parameters included: Discount rate of 6 percent (includes inflation); 20-year life cycle period; Cost of electricity: $0.1/kWh.

This analysis quantified the carbon footprint as a result of carbon dioxide (CO2), methane (CH4), and nitrous oxide (N2O) emissions due to food waste processing in each method. Because the overall global warming effect of each of these gases differs, the global warming potentials of each gas were used to normalize the greenhouse gas (GHG) emissions to a common unit: the carbon dioxide equivalent, or CO2e. By convention, the global warming potential of carbon dioxide is equal to 1, while the global warming potentials of CH4 and N2O are 25 and 298 tons/ton CO2e , respectively. Emissions of GHG were separated into nonbiogenic and biogenic sources. Nonbiogenic sources included any emissions from electrical use or the combustion of fossil fuels, such as diesel. Methane and nitrous oxide emissions were considered nonbiogenic, regardless of the source of the emissions.

Where possible, capital and operating costs were based on typical industry values and literature cost curves. If literature values were used to estimate costs, the Engineering News-Record construction cost index was used to inflate them to 2009 dollars. If general cost guidance was not available, estimations were made based on labor costs for new assets, energy costs, and other operational and maintenance costs. Unless otherwise noted, all operating and maintenance costs reported in this study were assumed to be constant over the 20-year lifespan of the analysis.

For the landfill method, it was assumed that the food waste was commingled with MSW at the residence and transported to a transfer station. From the transfer station it was hauled to the landfill for disposal. The landfill operations were assumed to use soil for daily cover and compactors to spread and compact the waste. Leachate was assumed to be trucked and treated offsite at a WRF, as this is the most common form of leachate management for MSW landfills. The moisture content of food waste is more than adequate to allow for biological decomposition; therefore, biological degradation of food waste within the landfill was assumed to proceed spontaneously. Biogas produced from the decomposition of landfilled food waste was assumed to be captured in a tiered progression over time based on the age of the cell. Captured biogas was used to fuel an internal combustion engine-driven generator to produce electricity only (no heat recovery).

For the composting method, it was assumed that source separated food waste is first collected from residences alone and transported to the composting facility, where it is mixed with a bulking agent and piled into windrows. Because the bulking agent is such a critical component of the composting process, all of the calculations for the composting analysis included the extra mass of bulking agent required to effectively compost the food waste. It was assumed that the windrows were mechanically turned using self-propelled turning equipment that straddles the windrow. After active composting, the material is then moved into curing piles and subsequently transported offsite for land application.

For the food waste disposer method, it was assumed that the WRF had influent screens and grit removal, primary clarification, activated sludge treatment for carbonaceous biochemical oxygen demand (BOD) removal, hypochlorite disinfection of treated effluent, solids thickening, anaerobic digestion with CHP, biosolids dewatering, and biosolids land application. Each household was assumed to use a food waste disposer to preprocess and dispose of food waste into an existing sewer infrastructure for conveyance to the WRF. Essentially this method is a form of codigestion with many preprocessors located in residences.

For the direct anaerobic digestion method, source separated residential food waste was assumed to be collected curbside and transported to a local WRF. At the WRF, the food waste was processed and pumped directly into an anaerobic digester. The design of the digester was the same as that used in the food waste disposer method, with the exception that a sludge screen was installed on a circulation loop to further reduce particle size and remove inert materials. Biogas produced from the digestion process was collected and utilized in a CHP engine and residual biosolids were hauled offsite for land application.

For the mixed MRF method, it was assumed that recyclable materials were separated and extracted from a mixed MSW stream. MRFs typically employ several unit processes, each dedicated to extracting specific materials, such as metal, glass, plastic and organic matter (including food waste). While the technology for processing source separated recyclable materials is well established, the technology for the separation of mixed MSW is sometimes proprietary. The separation process used for this analysis is as follows: Food waste is unloaded to a receiving area, where it is visually inspected for hazardous materials and subsequently loaded onto conveyors for separation. The separation process splits the waste stream into sorting lines where the readily recyclable materials are removed. Then, a series of specialized, mechanical equipment provide additional sorting for metals, glass and organic matter. The organic fraction is ground and then hauled to a WRF for digestion. Overall, it was assumed that approximately 30 percent of the organic matter entering the facility is recovered for digestion, and the remaining 70 percent could not be recovered and was trucked to a landfill for disposal. The design of the landfill and WRF were the same as those assumed for their respective methods described above.

Carbon Footprint

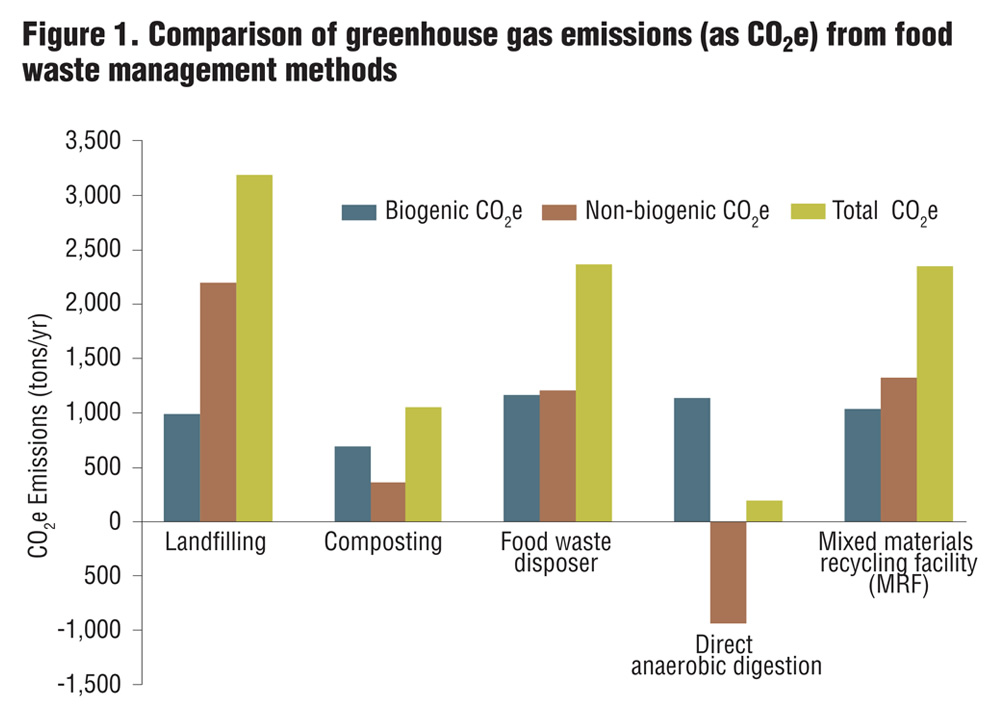

Biogenic, nonbiogenic, and total CO2e from the five food waste management methods are presented in Figure 1. In general, it was found that the carbon dioxide impact from each method was driven more by the biological degradation of the food waste stream than any of the processing or transportation steps.

The food waste disposer method had moderately high GHG emissions associated with fugitive methane release in the sewers. Little is known about the anaerobic decomposition rates in the sewer system. Thus, the impact of this assumption is large and provides a high degree of uncertainty to the results of CO2e emissions for the food waste disposer method. Out of all the five food waste management methods examined, the practice of using landfills to dispose of food waste had the highest carbon footprint.

Costs

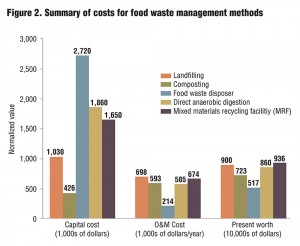

Costs of each of the management methods were estimated based on engineering knowledge, similar project experiences and unit process cost curves. Figure 2 shows the summary of estimated capital, operating, and present worth costs.

It should be noted that the WERF analysis did find that the food waste disposer method may, in fact, require the lowest capital investment when there is adequate capacity in the existing wastewater infrastructure to handle the additional loads. Also, while the food waste disposer method had the highest capital cost when incremental increases in infrastructure were assumed to be needed, the operating costs were the lowest in today’s dollars (present worth). The landfill and mixed MRF methods had the highest present worth costs, driven primarily by the high operating costs. The compost and direct anaerobic digestion methods had similar present worth estimates, despite significantly different capital costs.

Conclusions

Based upon the examination conducted in this study, there were advantages and disadvantages to each method of food waste management, which are summarized below:

The landfill method is currently the most prevalent means of handling food waste. Landfill disposal of food waste results in the highest emission of GHG and requires a relatively large area to implement. Further, landfill method costs appear to be among the highest of the food waste management methods. However, because most modern landfills capture and beneficially use landfill gas, the overall environmental and economic impacts are somewhat comparable to other common food waste management methods.

Composting had low carbon dioxide equivalent emissions and low present worth cost. However, the large area footprint requirement may make this method logistically unrealistic for municipalities limited on space. Composting of food waste is becoming more common as it is often collected with green waste.

Use of a food waste disposer for handling food waste within the existing sewer system for treatment at the WRF is economically attractive, having the lowest present worth cost of all the methods. The method also has minimal area footprint requirements. This method, however, requires potable water to convey the food waste in the sewers. While there is greater electricity demand for secondary aeration due to additional food waste, there is also additional energy production from anaerobic digestion. Food waste disposers have high public acceptance and provide convenient food waste handling to residents right in their kitchens.

Food waste trucked to the WRF and fed directly to the digesters had many advantages over other management methods. This method had the lowest carbon dioxide equivalent emissions, maximizes biogas production, decreases solid waste at landfills, and can provide a tipping fee revenue stream. However, this method requires source separated collection of food waste for direct injection into a WRF anaerobic digester. Separating and diverting organic wastes, such as food waste, from general waste or trash may exhibit both costs and benefits based upon community specific variables.

The environmental impacts of the mixed MRF method typically were midway between the direct anaerobic digestion method and the landfill method. The present worth costs, however, were high. This method is challenged by the potential for contamination of digestate from constituents in the MSW.

For a comprehensive understanding of converting food waste into biogas, it is helpful to evaluate the methods for food waste management, investigate the actual operation at a facility that converts food waste into biogas, and review the results of research focused on the anaerobic digestion of food waste. This analysis was not tailored to a specific application or even a general region, thus every attempt was made to generalize and simplify the assumptions used in this report to the extent possible. As a result, a potentially large degree of uncertainty was inherent to the processes examined. This analysis was meant to serve as a comparative study and provide some general guidance regarding sustainable food waste management. Because of its broad nature, the content of this report should be seen as a stepping stone or template for site-specific studies versus a comprehensive characterization.

A community may actually use several or all of the methods evaluated here. The results of this evaluation quantify some of the economic and environmental benefits of codigestion and present how they compare to other food waste management methods. The convenience to the residents and the operating requirements of the different methods must also be considered. The preferred food waste management method is dependent on the goals of the community and site-specific conditions. If cost and convenience is a major driver, a food waste disposer method may be preferred. If energy efficiency and low carbon footprint are the drivers, then a direct anaerobic digestion method could be preferred. If cost and carbon footprint are priorities and space is available, composting should be encouraged. Alternatively, if space and consumer interest are limited, a food waste disposer or mixed MRF method would be preferred. Three of the five methods evaluated involved codigestion and had economic and environmental benefits. Knowing these benefits will help to overcome the barriers to codigestion and result in wider implementation.

David L. Parry, PhD, PE, BCEE, is a senior vice president with CDM Smith. Subsequent articles in this series on codigestion will cover demonstration of converting food waste to biomethane fuel and insights regarding operation of codigestion facilities.