Both processes manage decomposition, carried out by biological organisms transforming the materials through chemical reactions. There are pros and cons to each process, and they can be used in series to enhance the value proposition of recycling organic materials.

Craig Coker

BioCycle March/April 2014

Composting and digestion are two often-used methods of processing biodegradable materials, including organics discarded as wastes. Many think they are different methods, but both are processes that manage decomposition, carried out by biological organisms transforming the materials through chemical reactions. Each process has inputs, products and by-products. The inputs are the materials being treated (feedstocks), which include sludges, manures, food scraps, etc. The outputs are those products with real or potential revenue value (compost, energy captured from composting piles or derived from biogas, and some digestates). The by-products are process outputs with real or perceived negative value (gases/odors, leachate, and some digestates).

The process of conversion of inputs to outputs differs between composting and digestion primarily due to the presence, or absence, of oxygen. Composting is an aerobic process, so oxygen is essential for its success. Digestion can be either aerobic or anaerobic, but is more often configured as an anaerobic process for the purpose of producing and capturing methane-rich biogas (aerobic digestion is used in some sewage sludge treatment schemes for stabilization and pasteurization, but is very energy-intensive).

Consider the biodegradation of simple sugar (glucose), both aerobically and anaerobically:

C6H12O6 + 6O2 g 6CO2 + 6H2O (aerobic)

C6H12O6 g 3CH4 + 3CO2 (anaerobic)

In composting, glucose is converted to carbon dioxide and water; in digestion, that glucose is converted to carbon dioxide and methane. How are these simple sugars created in composting and in digestion? Essentially, different groups of microorganisms break down more complex molecules, so that the microbes can utilize the underlying carbon substrates as food for their life processes.

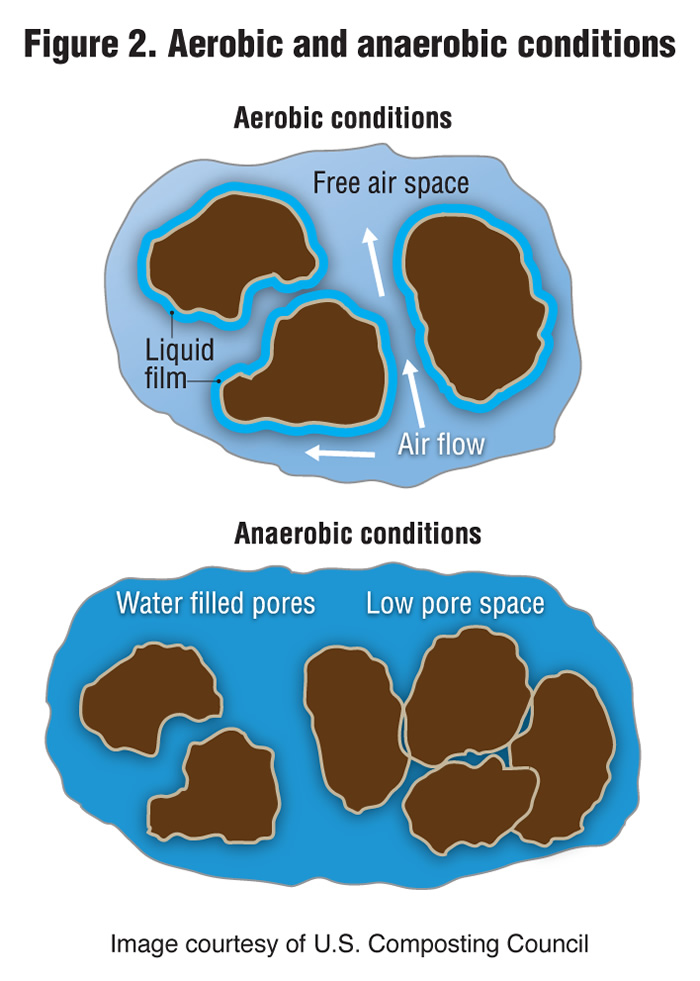

Take cellulose for example, which is contained in virtually every feedstock currently composted or digested. Cellulose is a polymer created by linking individual glucose molecules together. Figure 1 shows the molecular structure of cellulose; in this image, the white balls are hydrogen atoms, the black balls are carbon atoms, the red balls are oxygen atoms and the turquoise lines are electrostatic hydrogen bonds. The glucose components of cellulose are bound firmly between hydroxyl groups at one end and with oxygen atoms at the other end of the next link in the chain. These bonds can be broken through splitting a molecule with water (a process known as hydrolysis) by the enzyme cellulase, which is produced by certain types of thermophilic actinomycetes (i.e. Thermomonospora fusca, Trichoderma reesei) and fungi (i.e. Fusarium solani A. fumigatus) in aerobic composting. In anaerobic digestion, it is produced anaerobically by Cellulomonas sp. and Clostridium sp. bacteria.

More complex polymeric molecules, such as proteins, carbohydrates and lipids, are similarly biodegraded by several different types of microbes in each system. Composting systems use bacteria, fungi and actinomycetes, with minor roles from other protists such as algae and protozoa. Digestion systems use fermentative microbes (acidogens), hydrogen-producing, acetate-forming microbes (acetogens) and methane-producing microbes (methanogens). These organisms excrete enzymes (lipases, proteases, cellulases, amylases, etc.), which hydrolyze their respective polymers into smaller molecules.

Process Distinctions

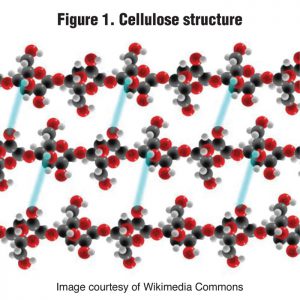

Another major difference between aerobic composting and anaerobic digestion is moisture content. Composting is most efficient with a moisture content of around 50 percent, which enables formation of a biofilm around each particle in the compost pile (Figure 2). Air moves through the structurally porous compost pile and transfers across the water layer boundary to provide air to the microbes living on the surface of the particle. Digestion systems operate best at 100 percent moisture content so that all pore spaces between the particles are filled and no air can get to the anaerobic microbes (Figure 2). The new European dry fermentation digesters being built in the U.S. also follow this principle as “percolate” is introduced into the mixed feedstocks to saturate them and fill the pore spaces with water.

Figure 2 also illustrates some similarities between composting and digestion in terms of particle sizes. Composting is most efficient (with regard to processing times) at particle sizes between a half-inch and 2 inches. Digestion efficiency (measured as biogas production rates and volumes) is greatest with smaller particle sizes. One study measured a 20 percent increase in biogas production between ~0.4 inches (10 mm) and ~1.2 inches (30 mm) (Hajji and Rhachi, 2013).

Composting is essentially a batch process, where feedstocks are mixed, degradation begins and produces heat, and after a period of time, the organic material is stabilized and no further biodegradation is occurring. Some composting systems on the market continually introduce feedstocks, however each particle in that reactor is essentially composting as a batch process with a defined beginning and end. Digestion, on the other hand, has the highest levels of biogas production when the system is being fed continuously. “In a reactor tank, you’ve got young substrate and old substrate mixed together, which are producing biogas at different rates, but the whole reactor is producing biogas continuously,” explains Paul Greene, Vice-President of O’Brien & Gere and a member of the Board of the American Biogas Council. “Conversely, in a dry fermentation system, which operates as a batch system, the biogas production drops off over time.”

The presence of oxygen in composting allows for a more complete decomposition of complex molecules into their simpler building blocks. For example, oxygen allows for the complete breakdown of carbohydrates into carbon dioxide and water (whereas low or no oxygen promotes the decomposition of carbohydrates into acetic acids). Aerobic bacteria, actinomycetes and fungi work together in composting to hydrolyze these complex molecules. The change in temperature in a compost pile reflects the activities of successive microbial populations performing the degradation of organic matter in the pile. During the mesophilic phase of composting, bacteria and fungi degrade the most available organics; as temperatures rise into thermophilic levels, different groups of bacteria, fungi and actinomycetes hydrolyze more complex molecules.

Digestion is a somewhat more complex process than composting, where the organic material is broken down through the sequential steps of hydrolysis, acidogenesis (the production of acids), acetogenesis (the production of acetic acid) and methanogenesis (the production of methane). As each process is ruled by different types of microorganisms, these steps operate more efficiently separately. “Yes, they are more efficient if kept separate,” notes Greene, “but you need to wrestle with the additional cost of another tank. Can the end user find enough benefit for the additional cost, which I would say is debatable?”

Digesters that operate at thermophilic temperatures (113-131°F or 45-55°C) produce more biogas and reduce more volatile solids than digesters that operate at mesophilic temperatures (95-104°F or 35-40°C) . The digestate from these high-rate reactors has less biological energy due to the reduction of volatile solids and less bio-available carbon due to the conversion of organic carbon to methane. This reduction in these “biological composting fuels” in those digestates can make them more difficult to compost in a follow-on process than digestates from lower-temperature reactors without supplementing the composting mix with fresh feedstocks. Many of the dry fermentation anaerobic digesters operating in Europe mix fresh yard trimmings and green waste in with the digestates removed from the reactors prior to composting.

System Outputs

Both biological processes produce solid, liquid and gaseous materials as part of the transformation process. Aerobic composting produces compost, water (both gaseous vapor and liquid leachate), and volatilized gases (ammonia, carbon dioxide and, occasionally, gases perceived as odors). Anaerobic digestion produces digestate and biogas. Most digestion systems in the U.S. are liquid systems (they operate at less than 5% total solids) so the digestate is often dewatered with mechanical devices producing a solids fraction and a liquid effluent. The liquid fraction is often land applied on crops for its nutrient value while the solids are either land applied, or, in some cases, composted. Composting is being used for digestate management at the newer dry fermentation systems being constructed, while land application is the preferred digestate management approach for farm-based manure digesters and biosolids digesters.

A recent European Union (EU) study (European Union, 2014) referred to a 2011 United Kingdom study that compared the overall environmental effects for several municipal solid waste management options, including composting and digestion, and concluded that digestion was better than composting in several areas (Table 1). The UK study was prepared by DEFRA (Department for Environment, Food and Rural Affairs) and observed that because digestion is an enclosed process, there are less impacts from dust, bioaerosols and odors than from composting (although proper siting can mitigate those impacts). The study also noted that the separated liquid fraction of digestate is a wastewater if not directly land applied to cropland or pasture and that fugitive emissions of methane and nitrous oxide (both significant greenhouse gases) will occur with land application of digestate. Several European studies have evaluated this, concluding that, while there are emissions of both methane and nitrous oxide from land application of digestate, methane emissions decline to background levels rather quickly and that N2O emissions are similar to those from urea fertilizer applications (Dieterich, 2012, Finnan, 2012).

Digestion is often pursued as a process to handle organic residuals when there is a potential energy market for the produced biogas. Biogas has an energy content of about 650 British Thermal Units (BTU) per cubic foot. “It takes about 1 pound of food scraps to produce 3.6 cubic feet of biogas, which would have an energy value of 2,160 BTUs,” notes Greene. This is equivalent to 4.3 million BTUs (mmBTUs) per ton of food scraps — enough energy to heat about 50 homes in the mid-Atlantic U.S.

Composting is not thought of as a process for recovering energy, but research in the northeast U.S. is investigating the capture of heat from active composting piles. “Today there are working examples of homes, greenhouses and farms that have used compost heat recovery systems alongside existing heating/hot water systems,” says Gaelan Brown of Agrilab, a Vermont company specializing in compost heat recovery systems. “These systems range from simple low tech designs made mostly of wood chips and sawdust, to large-scale engineered systems at farms and compost production facilities.” Brown offers examples in a new book to be published in 2014 (Brown, in press). One example notes an energy recovery of 1,500 BTU/hr from a dairy manure compost pile. As a mature cow produces 75 pounds of manure daily, this is equivalent to 0.96 mmBTUs per ton of manure.

There are substantial differences between compost and digestate. Table 2 presents a laboratory analysis of a food scraps compost and a food scraps digestate. The data shows that the digestate has more nitrogen than the compost (possibly due to N losses during composting), but has a C:N ratio of 14:1, low pH, high soluble salts, high CO2 respiration, and low metals and pathogens. The similarities and differences between compost and digestate will be explored more fully in a future article in BioCycle.

Composting and digestion are both proven methods of processing organic materials, particularly wastes, into value-added products using biological conversion methods. There are advantages and disadvantages to each process and they can be used in series to enhance the value proposition of recycling organic materials. Which approach to use (or both) depends, in large part, on markets for energy recovered in digestion, on siting considerations and proximity to sensitive receptors, and on final markets for products.

Craig Coker is a Contributing Editor to BioCycle and a Principal in the firm Coker Composting & Consulting (www.cokercompost.com), near Roanoke VA. He can be reached at cscoker@verizon.net.