T. O’Donnell, J. Deutsch, R. Pepino, B.J. Milliron, C. Yungmann and S. Katz

BioCycle October 2015

The Food System-Sensitive Methodology (FSSM) was introduced in 2015 as a systematic management paradigm for creating new solutions for food loss and waste prevention (for further details see O’Donnell et al., 2015). Economic approaches were advocated to support and expand on progress that has been made, but also limited, by a predominant focus on social and environmental factors. Most food system or food cycle studies focus on discussing food waste — failing to integrate the primary purpose for the food industry, which is to deliver healthy and nutritious food. Factors ranging from use of natural resources both in preparing land for raising food agriculturally all the way to safely digesting and metabolizing the food on our plates are completely within the realm of a food system-sensitive method. The FSSM methodology provides a way to understand and manage food systems that embrace economic, social, environment, natural resource use, biodiversity, health, and nutrition factors.

In the initial publication, we addressed the vast amount of food waste that currently ends up in costly landfills, which are considered a major source of methane production in the United States (USEPA, 2015a). We described practical ways to divert wholesome fruits and vegetables into the hands of Americans in hunger while using other diversion options according to available infrastructure for animal feed, anaerobic digestion and/or composting. Preventing waste rather than diverting or creating new waste, was shown to drive efficiency, create opportunity, and improve access to food. Moreover, through the FSSM, we also addressed the major moral issue arising from the approximate 40 percent wastage of all food produced for the U.S. food system.

On a weight basis, fruits and vegetables are at the top of the list of foods that are currently wasted (Gunders, 2012) but could be repurposed to relieve both hunger and nutritional imbalance in the diets of millions of members of our society in the greatest need. Our work with the FSSM also opened the door to reconsider new sources of nutrient and economic value in food resources that are being lost in our food system. New excitement and creativity arise through improving efficiencies throughout the food chain to correct vexing problems by using resources that are readily available.

This article further develops FSSM by addressing several key issues:

- Clarifies the economic potential of new food products and presents initial approaches for new social enterprises.

- Newly focuses on nutritional needs of the population (not just its caloric needs) and emphasizes the health potential of these new food sources flowing to the target communities.

- Addresses how this “food recovery” could be implemented with support of existing organizations, both charitable and entrepreneurial, including those responsible for food safety.

- Lays the groundwork for the FSSM to include other aspects of the food system that engage natural capital and resources that are both amenable to greater efficiency and greater benefits to our whole society.

Organics Management And Food Waste Prevention

The U.S. EPA Food Recovery Challenge was launched in 2011 to help organizations and individuals stop wasting food. The USDA added breadth to this initiative by launching its Food Waste Challenge in 2013 (USDA, 2013). Just recently, these two agencies joined together with private sector and charitable organizations to establish a 2030 goal for reducing food waste in the U.S. by 50 percent (USDA, 2015b). Many other groups continue to contribute to these efforts. For example, the Food Marketing Institute, Grocery Manufacturers Association and National Restaurant Association established their industry-based Food Waste Reduction Alliance in 2011. Internationally, food waste reduction activities continue to expand in places like the United Kingdom (WRAP, 2015), France (Geater, 2015), South Korea (Asia Today, 2013) and Japan (Marra, 2013). The growth in type, style, design, target and effectiveness of these activities are underpinned by the vast amount of food waste generated in all developed economies.

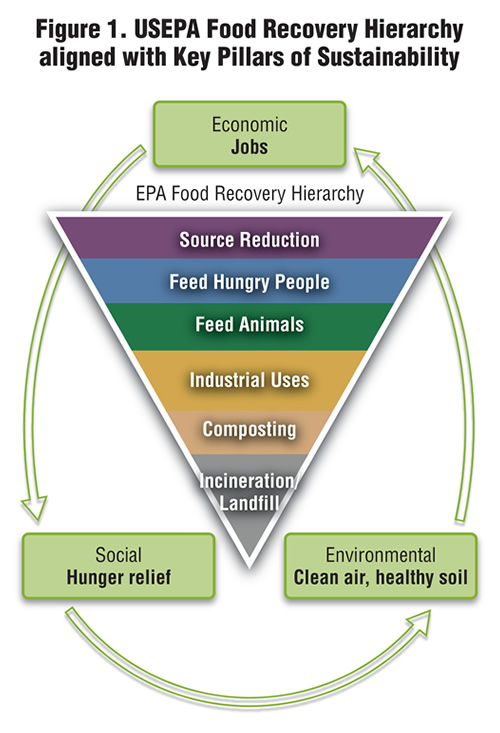

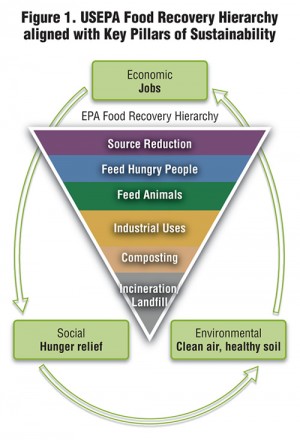

Landfills are the end of life for much of the retail food that is not eaten (USEPA, 2015b). Figure 1 shows the EPA Food Recovery hierarchy within the three pillars of sustainability. The hierarchy was tiered to prioritize food management alternatives, starting at the top with prevention and ending up the bottom with landfill disposal. Prevention is the best antidote to waste, and fortunately, new creative methodologies to prevent food waste are surfacing and being explored here and abroad (USDA, 2015c; European Commission, 2015). Because retail food waste originates from for profit businesses, economic factors may prove to be the most powerful driver to prevention. Figure 2 illustrates more specifically how a focus on economic solutions for supermarket food waste can create fully sustainable options for the supermarket industry.

Previously, much of the emphasis on cost benefits to supermarket hunger-relief donations has been on lowered waste hauling fees or tax credits along with a difficult to measure brand marketing benefit (Feeding America, 2015). This does little to correct for unearned revenue. The FSSM approach offers a solution by showing how to safely convert cosmetically second, expired date labeled, overstocked, or ripe produce into new enhanced products. Safe nutritious food is kept in the food chain by creating products for business or for better use by food shelters. Conversion methods have the potential to reduce the amount of food leaving supermarkets as waste by 64 percent (O’Donnell et al. 2015), while still leaving significant amounts for other beneficial uses like donation, composting and/or anaerobic digestion.

Surplus Supermarket Produce Scenarios

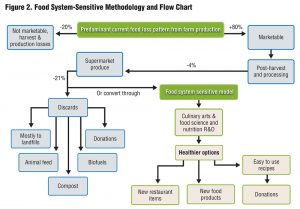

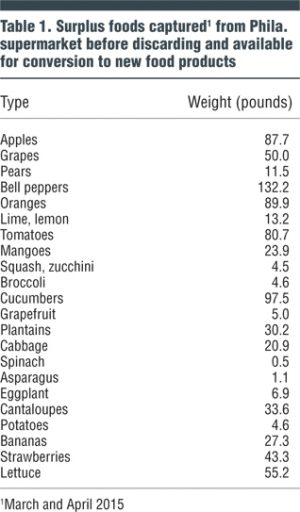

Table 1 is a list of produce that was captured from a supermarket in west Philadelphia just before it was sent off-site for reuse or disposal. These were all culled from the customer facing displays by store personnel using their standard practices for removing food for sale. The food was weighed and returned to the Drexel University Food Lab for further evaluation. The data set was collected from one store, one day each week in March and April, 2015. The food types and weights were used as the basis for building four scenarios — business, social, environmental, and educational scenarios. Part I of this article covers the business scenario in the form of a social enterprise. Part II covers the other three scenarios.

Scenario 1:

Social Enterprise—Repurposing Tomatoes

In a relatively slow month, a regional supermarket chain discarded approximately 35,000 pounds (lbs) of fresh fruits and vegetables. Of the total, approximately 25 percent (8,750 lbs) is unusable — spoiled, severely bruised, and so on. Ten percent (2,625 lbs) is too specialized to be commercially viable (prickly pear cactus, kumquat, nopales, etc.). After culling for these categories, approximately 12 percent (2,835 lbs or nearly 1.5 tons) was tomatoes.

These tomatoes, as they approach peak ripeness, are soft and fragile; skins often split which make them visually unappealing and messy. They are pulled from store shelves and are typically composted, or in some cases, landfilled by the supermarket. Tomatoes are typically not accepted for food donations once they are bruised or splitting. However, they are at peak deliciousness and nutrient density at that time.

Our working hypothesis is that those 2,835 pounds of tomatoes could be locally processed by a social enterprise, possibly in weekly batches of 700 pounds, which would take a full day to process in a commercial kitchen, depending on the recipe. Rather than composting or landfilling those tomatoes at a cost to the supermarket, they are carted away by a social enterprise for free or even at a token payment to the supermarket of $.10/lb, turning a market cost into revenue of $283.50. Next, the social enterprise uses a simple recipe such as tomato jam where tomatoes are quickly washed, sorted and cooked down in a steam-jacketed kettle to about 20 percent of their starting weight with another 9 percent of added ingredients. This yields 205 lbs/week packaged in 410 8-ounce jars, or 1,640/month.

Of course, yield can be further increased by cooking the tomatoes less and adding sugar and acid but the economics of this recipe flip the usual food processing techniques designed to extend the usually expensive tomato ingredient by adding supplements like sugar, salt and acids to help stretch the main ingredient. In this case, since our main ingredient is surplus and the cheapest, it is best cooked down to exploit its natural sugars, salts, acids and rich flavor, without the extra sugar calories or the added sodium from salt. This minimizes the added ingredient costs — for the tomato jam, 1 lb of sugar is used per 12 lbs of tomatoes; 1 lb of salt is sufficient for about half of the lbs. A formula for 100 lbs of tomatoes (to yield 29 lbs of jam): 100% tomatoes, 8% sugar, 0.3% salt, and 0.1% each of citric acid, ground ginger, ground cinnamon, ground cumin and ground cayenne.

From a simplified cost perspective, added costs on 100 lbs of tomatoes is less than $10 at wholesale prices, making each 100 lb formula approximately $20 in food costs (100 lbs of tomatoes at $.10/lb plus added ingredients). The 29 lbs yielded 58, 8-ounce jars at a food cost, then, of $0.35 per jar. Labor for 700 lbs takes a full day for cooking and packaging with washing and filling the most labor intensive parts of the day. For simplification, imagine three workers on a 10-hour shift (in reality, shifts could be staggered because the beginning and end of the day are the only parts that require three people) at $15/hour. Labor cost for the day would be $450. Labor cost for the 100 lb formula (58 jars) would be $64.29 or $1.10 per jar, admittedly high by food manufacturing standards.

Total prime cost (food and labor together) would be $1.45. Still, to employ three workers at a family wage, a social enterprise may see some benefit. Adding the cost of the jar, use of a certified kitchen incubator and local transportation yields a $2 product that could be wholesaled back to the retailer for $3 and retailed for $4.99, generating $3,263 (1,640 jars x 1.99) for the retailer and $1,640 ($1 per jar) in gross profits to the social enterprise, which will have additional expenses like marketing, technical assistance and insurance, but also, potentially, some profits.

Of course, tomato jam is only one example selected to convert one of the most commonly wasted supermarket vegetables. Recipes also are being developed to deal with the other common variations in food product availability, which could make the enterprise more profitable. In addition, other food specialty recipes could be used along with careful incorporation of processing steps that could improve flavor and nutrient potential of the products.

Part II of this article will cover three other scenarios: Social and health benefits; Environmental benefits; and Education and outreach.

Author affiliations: Thomas H. O’Donnell, Land and Chemicals Division, U. S. Environmental Protection Agency, N.A.H.E., Region 3, Philadelphia, PA (odonnell.tom@epa.gov); Jonathan Deutsch, Department of Culinary Arts and Food Science, Center for Hospitality and Sport Management, Drexel University, Philadelphia, PA, (jdeutsch@drexel.edu); Richard Pepino, Drexel Food Lab, Center for Hospitality and Sports Management, Drexel University, Philadelphia, PA, (richard.vincent.pepino@drexel.edu); Brandy-Joe Milliron, Department of Nutrition Sciences, Drexel University, Philadelphia, PA (brandy-joe.milliron@drexel.edu); Cathy Yungmann, Department of Communication, Cabrini College, Radnor, PA, (cathy.yungmann@cabrini.edu); Solomon H. Katz, Krogman Center for Research in Child Growth and Development, University of Pennsylvania, CEO World Food Forum, Philadelphia, PA (skatz2001@aol.com).

Acknowledgements: The authors gratefully acknowledge the many individuals and organizations that supported and continue to support this research, especially the owners and staff of Brown’s Super Stores in Philadelphia, Jeff Brown, Tim Nolf, and David Deets, and others including: Cabrini College Communication Students Nick Cipollone, Amber Marshall, Lauren Hight, Greg Smith under the direction of Cathy Yungmann, and Drexel support from Alexandra Zietz and Daniel Yohe.

Disclaimer: Any views expressed in this report do not necessarily represent those of neither the United States government nor the Environmental Protection Agency. Mention of trade names or commercial products does not constitute endorsement or recommendation for use.

References

Asia Today, April 25, 2013, South Korea’s Food Waste Solution: You Waste, You Pay.

European Commission, 2015, Good practices in food waste prevention and reduction.

Feeding America, 2015, Tax Benefits for your Company.

Food Waste Reduction Alliance, n.d.

Geater, M, September 9, 2015, French retailers agree to fight food waste, EU Food Law Country Reports.

Gunders, D., 2012, Wasted: How America Is Losing Up to 40 Percent of Its Food from Farm to Fork to Landfill, NRDC Issue Paper, 12-06-B.

Marra, F., November 27, 2013, Food Waste in Japan: How Eco-towns and Recycling Loops are Encouraging Self-Sufficiency, Food Tank.

O’Donnell, T., Deutsch, J., Yungmann, C., Zeitz, A. and Katz, S. (2015) New Sustainable Market Opportunities for Surplus Food: A Food System-Sensitive Methodology (FSSM). Food and Nutrition Sciences, 6, 883-892. doi: 10.4236/fns.2015.610093.

USDA, 2015a, Selected New and Ongoing USDA Food Loss and Waste Reduction Activities.

USDA, 2015b, USDA and EPA Join with Private Sector, Charitable Organizations to Set Nation’s First Food Waste Reduction Goals2015b, news release # Release No. 0257.15.

USDA, Choose My Plate.gov.

USEPA, 2015a, Sustainable Management of Food Basics.

USEPA, 2015b, Overview of Greenhouse Gases, retrieved 0915.

WRAP, 2015, United Kingdom, Food Waste Reduction.