Mixing maintains integrity of the decomposition process by improving circulation and consistency, and minimizing volumes of the scum and grit layers.

Craig Coker and Gene Smith

BioCycle February 2017

Regardless of reactor type, all AD plants operate on the same sequential biological principles of anaerobic decomposition: hydrolysis of proteins, cellulose, lipids and other complex organics into more soluble forms; conversion of those solutes into organic acids; and conversion of those acids into biogas, resulting in the residual digestate. These conversion processes consume the volatile solids in the substrates (feedstocks) being digested, which stabilize the substrate through reduction in its putrescibility, and is important to formation of a high quality digestate.

The main factors that influence the rates (and, therefore, the success) of these biological transformations in the AD reactor are hydraulic and solids residence time (HRT/SRT), temperature, pH and the presence of toxic materials. HRT/SRT and the rate waste is fed influence the size of the AD reactor. Temperature determines the rate of hydrolysis and methane formation, so uniformity in temperature is an important consideration. The anaerobic bacteria that produce the methane (which forms the basis of biogas) are sensitive to the pH of the substrate they live in.

Why Mix?

Production of organic acids in the second stage of AD lowers the pH, which can inhibit the formation rate of methane. (This is buffered somewhat by an increase in alkalinity through formation of carbon dioxide.) Feeding large quantities of fresh substrates into the AD reactor can also depress pH, which can be mitigated by good mixing inside the reactor. Mixing systems can also reduce the impact of toxic materials (i.e. ammonia) by diluting it in the reactor volume below levels that would inhibit methane formation. Homogeneity of the digestate and rapid and thorough incorporation of new feed to a CSTR type digester is also important to the rate at which the various steps in the process occur, and how effectively the volatile solids are converted.

In short, the two basic reasons for mixing digester reactor contents are to: 1) Maintain the integrity of the decomposition process by improving circulation and consistency (physical and thermal) in the reactor; and 2) Minimize the volumes of the scum and grit layers by keeping these fractions dispersed in the substrate. More energy is needed to keep heavy solids in suspension than to homogenize the reactor contents.

Mixing Methods

Reactor contents can be mixed with recirculated biogas gas, recirculation of the digester contents with a pump and system of nozzles, or mechanical agitation. Each has advantages and disadvantages. There are a number of design criteria for mixing systems used by different digester designers. These include power input, velocity gradient, and turnover time.

Power input (measured in horsepower per 1,000 cubic feet, or hp/1000ft3) is based on the observation that mixing efficiency and power input are closely related. This depends on the actual configuration of the mixing system and on efficient distribution of the power supplied through the entire tank volume. Typical values for power input are 0.2 to 0.3 hp/1000 ft3.

Velocity gradient is a measure of mixing intensity, where the gradient is measured per unit time and is a function of power input, liquid viscosity and digester volume. A more viscous liquid will have a lower velocity gradient. Typical velocity gradients are 50 to 80 sec-1 (see Q&A in online version to learn more). Turnover time is the time required to recirculate the entire contents of the reactor and is calculated as the total volume of the reactor divided by the pumping rate through the mixing device. Typical designs are based on achieving a turnover time of 30 to 60 minutes.

A similar mixing system is pumped agitation, in which some of the liquid tank contents are withdrawn from the reactor by external mixing pumps and reinjected back into the reactor through discharge nozzles at the bottom. The action is similar to how swimming pool water is recirculated after removal and filtration. Usually, a chopper version of a centrifugal pump is used.

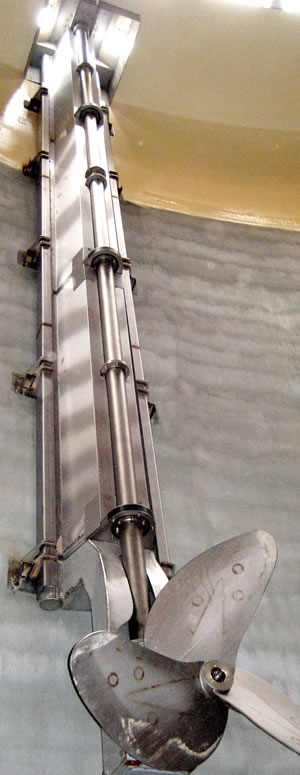

Mechanical mixing systems use rotating propellers to mix the digester contents. The mixer uses propellers that are either low speed, larger diameter or higher speed, smaller diameter. Propellers are usually exposed in the digester or may be mounted in draft tubes (to direct the flow within the reactor).

The flow pattern for top entry mixers is usually top-to-bottom, whereas gas and pumped agitation mixing systems have a bottom-to-top flow pattern. Mechanical mixers in draft tubes have reversible mixing patterns and can be mounted on the reactor roof or on the reactor sidewalls.

Mechanical mixers can also be high speed or low speed submersible mixers mounted on mast systems, or side entry mixers with rotating shafts penetrating the sidewall or located inside mixing (draft) tubes. Side entry and submersible mixers are aimed to create a balance of radial and tangential motion to homogenize the digester.

Vertical linear motion mixers are top entry and use disc-shaped perforated plates mounted at the end of a long shaft powered by its own motor.

Mixing Considerations

Several factors should be considered when planning on gas recirculation, pumped agitation, or mechanical mixers. Factors include capital and operating costs, maintenance requirements, process configuration and particle size and consistency of the substrate in the reactor. As reactor solids — and in the case of manure digesters, fiber content — increases, viscosity and non-Newtonian behavior (see Q&A in online version for explanation) usually increases, which requires more energy for mixing. Energy for mixing that is diverted from sale of biogas-produced energy is referred to as parasitic power. Parasitic energy demands are often higher with gas or pumped mixing systems due to the energies needed for compression and for fluid movement.

Mixing strategies during normal operations can be either intermittent or continuous. Intermittent mixing can use less power, but with continuous mixing, mass and heat transfer to the microbes is enhanced, similar to continuous versus batch feeding of substrate to the reactor. For thicker substrates, a greater proportion of mixing time is recommended as the dynamic energy losses will be higher.

Good and reliable mixing in digesters will provide a more uniform environment for microbial degradation, enhance biological reaction rates, improve volatile solids reduction efficiencies and reduce potential for process upsets while improving the operating safety margin at the facility.

Craig Coker is a sanitary engineer, Senior Editor at BioCycle and CEO of Coker Organics Recycling (www.cokercompost.com) near Roanoke, Virginia (ccoker@jgpress.com). Gene Smith is an Applications Engineer with SUMA America, Inc., a technology provider for digester mixers and agitators (gene@gosuma.com).