BioCycle November/December 2018

Food Waste Recovery Strategy

The City of Baltimore, Maryland’s Office of Sustainability recently released its “Food Waste Recovery Strategy,” written in partnership with the Institute for Local Self-Reliance (ILSR) in Washington, D.C. The strategy recommends ways that Baltimore can recover edible food, reduce food waste, and compost food scraps. The Office of Sustainability drew on ILSR’s Hierarchy to Reduce Food Waste and Build Community when developing its strategy. “Locally based composting keeps dollars in the community, promotes strong neighborhoods, cleans and enriches Baltimore’s soil, and importantly, supports local food production and food security,” said Baltimore Mayor Catherine Pugh. Goals outlined in the strategy include:

• Reduce commercial food waste in Baltimore City by 50 percent by 2040

• Eliminate all food waste from higher education institutions by 2040

• Divert 90 percent of food and organic waste generated by Baltimore City government agencies from landfill or incineration by 2040

• Reduce household food waste in Baltimore City by 80 percent by 2040

• Ensure all Baltimore City residents have access to organic waste collection at home or in their neighborhoods by 2040

• Divert 80 percent of residential food and organic waste from landfill or incineration by 2040

• Create composting and/or anaerobic digestion facilities in the Baltimore region capable of processing all of Baltimore City’s organic waste by 2040

• Support the food waste diversion market by ensuring an adequate supply of organic waste is being diverted to composting and anaerobic digestion facilities

• Attain 90 percent food and recyclable waste diversion in Baltimore City K-12 schools by 2040

• Create a supportive culture for food waste reduction and diversion in K-12 students, faculty, and staff

The report features seven case studies of food rescue and recovery projects in Baltimore. These include Goucher College Food Recovery Network and the Franciscan Center under the “Food Waste Reduction and Recovery” potential solution category; Real Food Farm and the Baltimore Compost Collective for “Composting at Home and in the Community;” Johns Hopkins University Homewood Campus and Camp Small under “Creating Scalable Composting Infrastructure;” and Federal Hill Preparatory School for “Composting in K-12 Schools.”

“Damn Real”

Jerry Brown is leaving the California governorship after 16 years in office. Wrote Evan Edgar with the California Compost Coalition in its October newsletter: “He built an aggressive state climate change mitigation and adaptation program with a robust cap-and-trade mechanism. The California GDP (gross domestic product) grew to the fifth largest economy in the world as carbon intensity decreased. …. The governor will be remembered for his Global Climate Action persona and taking ambition to the next level.”

In an impassioned speech in July 2017 to a room packed with activists, lobbyists and lawmakers about the extension of California’s Cap-and-Trade program to 2030, Gov. Brown said: “I’m not here about some cockamamie legacy that people talk about. This isn’t for me. I’m going to be dead. It’s for you and it’s damn real.”

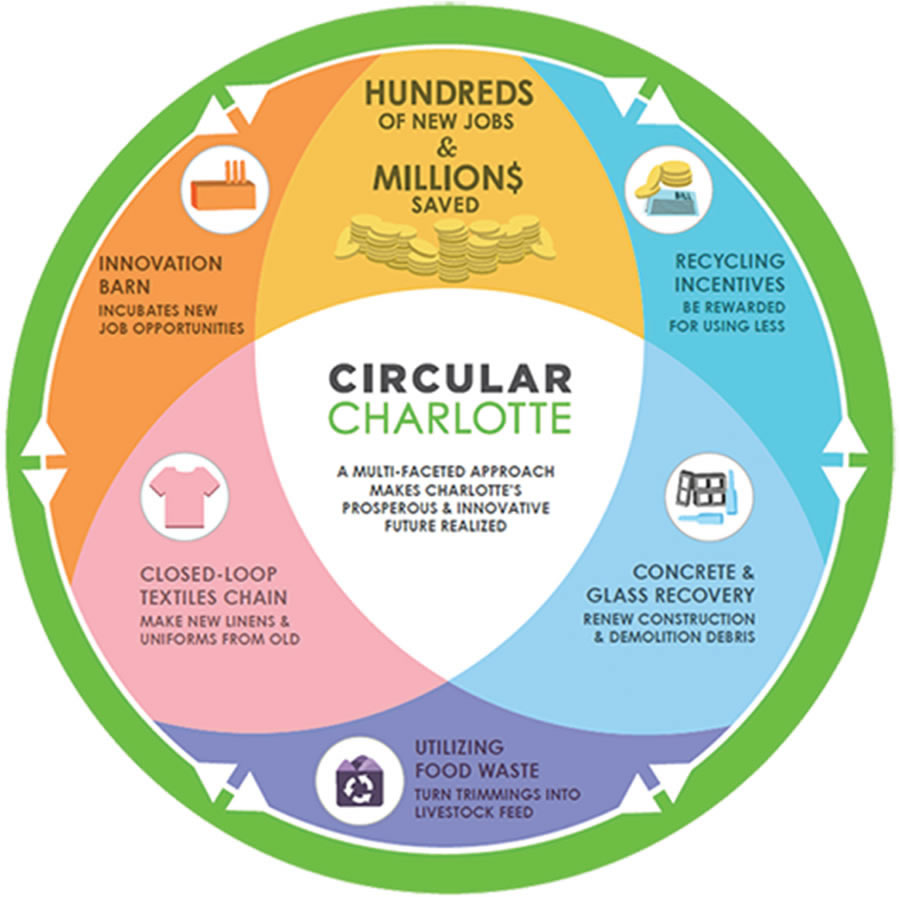

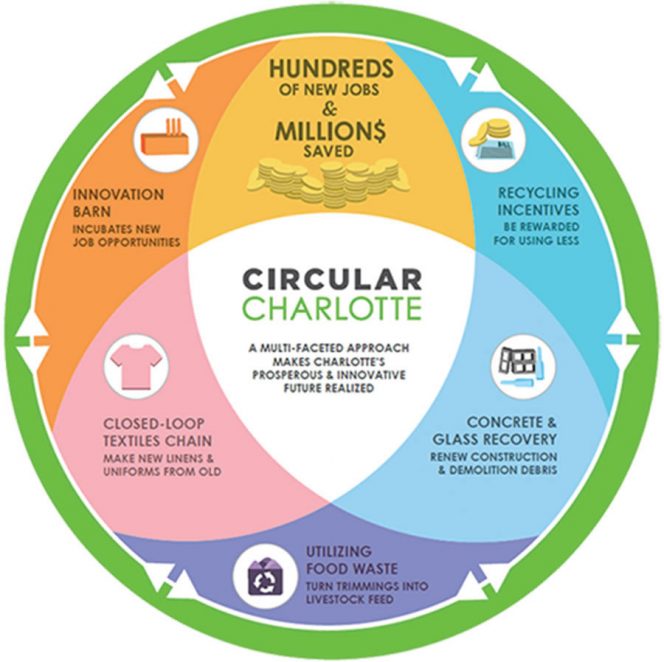

Circular Charlotte

The City of Charlotte, North Carolina released a study in October — Circular Charlotte: Toward a Zero Waste and Inclusive City — that features a roadmap to balance economic growth while preserving natural resources. The study analyzed Charlotte’s waste stream and found that the 900,000 tons of waste generated annually represent a potential residual value of roughly $111 million/year. The city’s current recycling and composting rate is 11.5 percent. “By simply adopting a comprehensive waste diversion strategy, Charlotte could create hundreds of jobs by harnessing material instead of dumping it into landfills,” said a press release, noting that “Charlotte is the first city in the United States to make a commitment to adopting the circular economy as a public sector strategy.”

The City of Charlotte, North Carolina released a study in October — Circular Charlotte: Toward a Zero Waste and Inclusive City — that features a roadmap to balance economic growth while preserving natural resources. The study analyzed Charlotte’s waste stream and found that the 900,000 tons of waste generated annually represent a potential residual value of roughly $111 million/year. The city’s current recycling and composting rate is 11.5 percent. “By simply adopting a comprehensive waste diversion strategy, Charlotte could create hundreds of jobs by harnessing material instead of dumping it into landfills,” said a press release, noting that “Charlotte is the first city in the United States to make a commitment to adopting the circular economy as a public sector strategy.”

Five business cases were created to serve as the foundation for Circular Charlotte. To begin implementation, the City will focus on four of the five:

• Creation of hundreds of jobs by developing a circular industry based on feeding 50,000 tons of food waste to black soldier fly larvae, which can be converted into pellets to use as feed on North Carolina poultry farms.

• Saving hundreds of thousands of gallons of water by developing a closed-loop textiles chain for linens and uniforms used in hotels and hospitals, cutting demand for environmentally damaging cotton and polyester production and offering opportunities to work in a whole new industry.

• Providing entrepreneurs (who might not otherwise be able to afford to develop their circular economy business ideas) with equipment, expert advice, and commercial feedback to develop circular economy business ideas at a startup incubator located at Envision Charlotte’s Innovation Barn.

• Avoidance of 41,186 CO2e (carbon dioxide equivalent) emissions by transforming concrete from demolition sites and powder made from discarded glass into new concrete, also a job creator.

The City of Charlotte is rolling out the strategy gradually, beginning with a $2 million investment in the Innovation Barn. Envision Charlotte, a nonprofit organization, and Metabolic, a circular economy consulting firm, collaborated with the city on the Circular Charlotte study.

“Spin Cycle”

BioCycle columnist and University of Washington Research Associate Professor Sally Brown writes a scientific literature review column for the Northwest Biosolids newsletter. In October, she focused on microplastics (MP). The following is excerpted from Dr. Brown’s review of two papers:

Polyester textiles as a source of microplastics from households: A mechanistic study to understand microfiber release during washing examines “the premier pathway for microplastics from the home to the treatment plant: the washing machine” (about 1,900 fibers per wash, according to the second paper). The authors utilized a laboratory version of a washing machine, and considered different types of fabrics, detergents, temperatures, and length of cycle. Using detergent resulted in more MP being released. Further, installing a filter in the washer would miss most of the MP.

Microplastics in sewage sludge: effects of treatment traces the fate of these particles during wastewater treatment. It turns out that different biosolids stabilization systems produce different amounts of MP. The systems that involve the harshest environments — lime stabilization and thermal drying — tend to produce the most MP (up to 13,675/kg dry matter). In contrast, anaerobic digestion, a relatively gentle process, produces fewer MP (2,000-4,000/kg dry matter).

Slowing Food Decay

Apeel Sciences, a California-based company founded in 2012 by James Rogers with a grant from the Bill & Melinda Gates Foundation, utilizes advances in materials science to prevent spoilage of fresh produce. Food typically rots when moisture exits, oxygen gets in and mold takes over. Apeel is made of plant-derived materials — lipids and glycerolipids — that naturally exist in the peels, seeds and pulp of fruits and vegetables. The skins, seeds and pulp of homogeneous fruits or vegetables, such as grapes from a winery or tomato skins from a ketchup factory, are pressed, and the oil that comes out is rich in fat lipids. The oil is converted into a colorless, odorless, tasteless powder tailored for each type of produce to which it will be applied. At produce packaging facilities, the powder is mixed with water and produce is either rinsed in or sprayed with the mixture, essentially creating a second “peel.” According to Apeel, the process doubles the shelf life of fruits and vegetables.