Oregon DEQ study analyzed if materials with compostable and biobased attributes consistently have lower environmental impacts than materials without the attributes.

D. Allaway, J. Rivin, M. Mistry and P. Canepa

BioCycle March/April 2019

Oregon’s 2050 Vision for Sustainable Materials Management places solid waste and recovery activities in a larger policy context: higher order goals of conserving resources and reducing pollution across the entire life cycle of materials. That life cycle includes but is not limited to management at end-of-life such as composting or landfilling.

In the spirit of achieving broader environmental and social goals — such as healthy soils, a stable climate, and a sustainable level of resource use (as opposed to simply diverting waste from disposal) — the Oregon Department of Environmental Quality (DEQ) commissioned research that opens a new question in the evolving discourse about packaging: Do biobased, compostable, recycled content, and recyclable materials inherently and consistently result in lower impacts to the environment when impacts are measured across their full life cycle? For compostable packaging, that life cycle includes the impacts and benefits of composting, but also the impacts of producing material feedstocks, packaging manufacture, transport and use.

Attributes Vs. Impacts

Purchasers often seek products that minimize impacts on the environment. Policymakers often seek to grow the market for such “low impact” products as well. Many impacts, such as greenhouse gas emissions, resource depletion, and the emissions of toxic chemicals can be estimated quantitatively using life cycle assessment (LCA). LCA does not address all impacts (such as impacts from marine debris), and can be complicated and costly.

Rather than using LCA, a simpler framework for evaluating and comparing materials is often used: attributes. Common attributes such as recycled content or compostable are easy to understand and communicate. It is widely believed that such attributes correlate with lower environmental impact materials and thus serve as reasonable proxies for making low impact choices. But do materials with these attributes consistently have lower environmental impacts than materials without the attributes?

Working with Franklin Associates, a LCA consultant, DEQ explored that question by conducting a meta-analysis of existing literature. The process drew upon existing LCA studies of packaging and food serviceware by academia, government and industry worldwide, rather than commissioning original analyses. This allowed the researchers to understand the overall trends based on a large body of published research.

The scope of the study encompassed two classes of materials — packaging and food serviceware — and four attributes: recycled content, recyclable, biobased and compostable. The information presented in this article covers only biobased and compostable attributes. Reports on all four attributes are available on DEQ’s website.

Research Methods

Franklin Associates reviewed existing LCA studies from across the globe that were published between 2000 and 2017. Because LCA studies can rely on different accounting frameworks and background data, impact results from one study were not compared against impact results from a different study. Instead, “paired comparisons” within the same study were used: for example, a compostable drink cup compared against a non-compostable drink cup, both modeled for life cycle impacts using the same accounting framework and data sources. Results from such a paired comparison for any one type of impact (such as ecotoxicity potential) counted as one “comparison.” The available research produced several thousand of these comparisons.

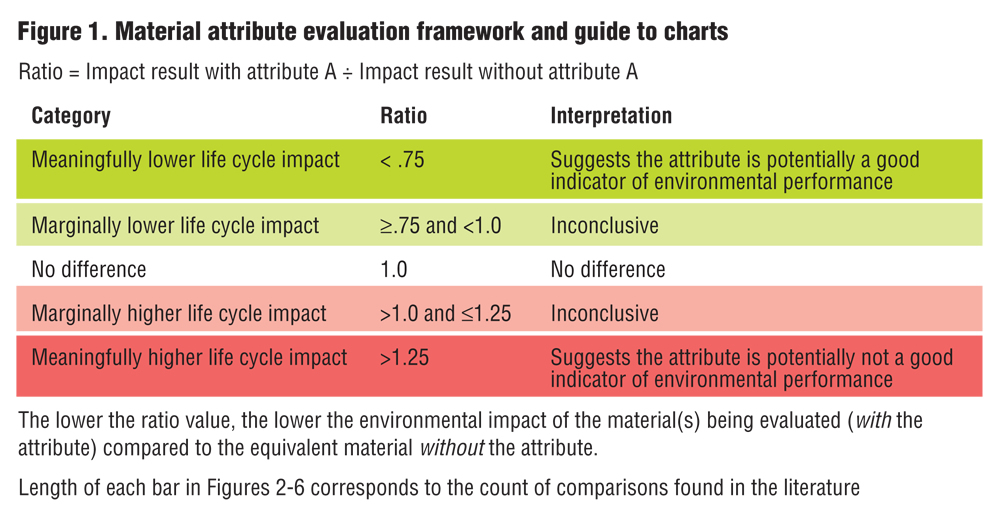

To aid in evaluation and visualization of results, an algorithm was created to categorize findings. This system involved the calculation of a simple ratio. For each paired comparison, the ratio is the impact result for the material with the attribute in question, divided by the result for the same impact category for a functionally equivalent material without or with less of the same attribute. Ratios less than 1.0 suggest that the attribute points in the direction of environmental preference (fewer toxics, less energy use, etc.), while ratios greater than 1.0 show a higher impact. Given uncertainty in many LCA studies, we also drew a distinction between “meaningful” and “inconclusive” differences. The categorization system is shown in Figure 1.

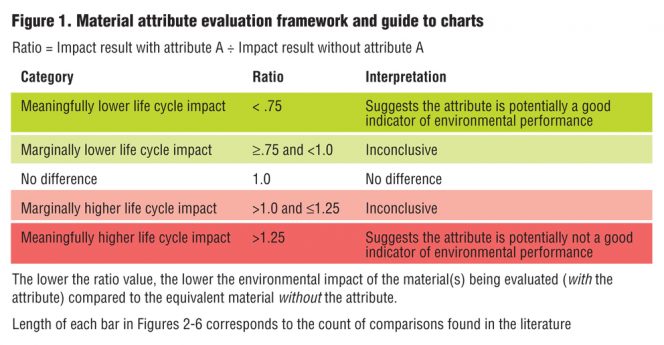

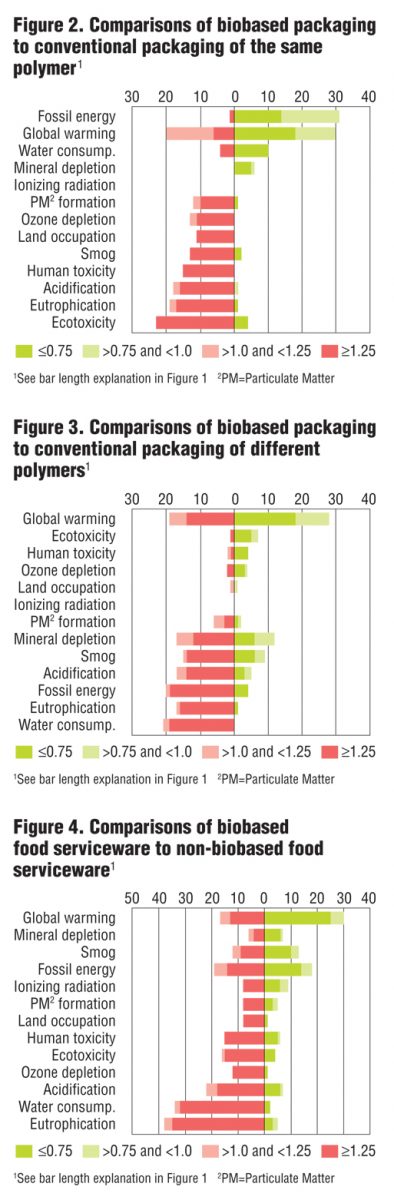

Figure 2. Comparisons of biobased packaging to conventional packaging of the same polymer

Figure 3. Comparisons of biobased packaging to conventional packaging of different polymers

Figure 4. Comparisons of biobased food serviceware to non-biobased food serviceware

Results

Biobased

Figure 2 shows the results comparing biobased to non-biobased plastic packaging for the same resins. An example is PET (Polyethylene terephthalate) made from plant-derived sources (such as “bio-PET” from sugar cane), compared against PET made from fossil fuels. In this figure (and all subsequent figures), the length of the dark green bars indicate the number of comparisons in the literature where a package with the attribute of interest (in this case, biobased) was found to meaningfully reduce impacts (impact ratio <0.75) when compared against an alternative package without that attribute (in this case, non-biobased).

The length of red bars indicate the opposite: the attribute of interest (in Figure 2, biobased) was found to significantly increase impacts (impact ratio >1.25) relative to the alternative without the attribute. Green indicates comparisons showing that the attribute leads to better results (lower impacts); red shows the opposite (higher impacts). If an attribute consistently leads to lower impact choices, the chart will be mostly green.

Figure 2 shows at a glance what 18 years of LCA research into biobased plastics reveals. Not surprisingly, biobased plastics, when compared against non-biobased plastics, almost always were found to reduce fossil energy use and mineral depletion. They also typically reduce water consumption. However, the literature shows that biobased plastics often increase net impacts for land occupation, ecotoxicity and eutrophication, mostly as a result of agricultural runoff associated with growing the inputs (feedstocks). For global warming the results are mixed, pointing to significant tradeoffs associated with biobased feedstocks.

Figure 3 compares biobased and non-biobased for different polymers (for example, biobased PLA vs. conventional PET). It shows mixed results for global warming, and generally worse impacts (for biobased) in the categories of smog, acidificiation, and eutrophication. Interestingly, several results are reversed from Figure 2 — biobased materials tended to have lower toxicity impacts, but result in higher fossil energy use. This shows that different materials have inherently different impact profiles, and simple feedstock substitution isn’t always a reliable way to reduce environmental impacts.

Figure 4 shows comparisons for biobased vs. non-biobased food serviceware items, such as cups and clamshells. As before, the length of green bars is the count of comparisons where the attribute (biobased) is associated with lower impacts; red bars represent comparisons where biobased is associated with higher impacts. The results are mixed with a tendency towards the red (showing higher impacts for biobased items). One interesting result stands out in the category of fossil fuel depletion, as an increasing number of businesses are acting to phase out “fossil based” food service items. The literature showed near perfect symmetry in the number of comparisons. Fossil based plastics obviously require use of fossil fuels. However, the production of biobased materials and their agricultural feedstocks typically also require use of fossil fuels, and in half of comparisons the net quantity of fossil fuels used for biobased items was found to be higher.

In summary, “biobased” as an attribute was found to be an unreliable indicator of reduced environmental impacts for packaging and food serviceware items. Therefore, simply using biobased as a criterion for reducing environmental impacts is not advisable.

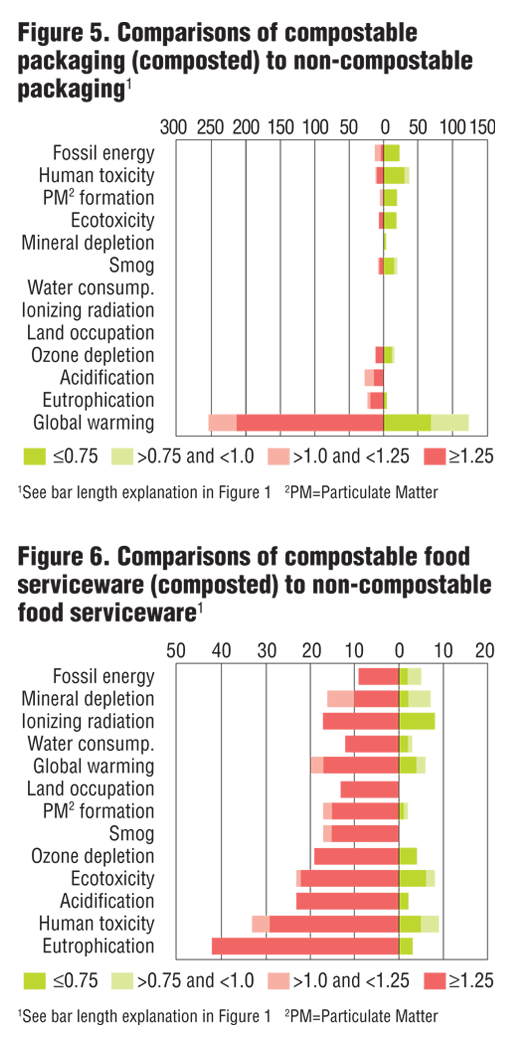

Figure 5. Comparisons of compostable packaging (composted) to non-compostable packaging

Figure 6. Comparisons of compostable food serviceware (composted) to non-compostable food serviceware

Compostable

Figure 5 shows the comparisons for compostable packaging (composted) against non-compostable items (not composted). An example of this would be a starch-based espresso capsule, compared against an aluminum espresso capsule. As with other attributes, no consistent pattern emerges. The compostable attribute is not a reliable predictor of environmental impact or benefit.

Figure 6 shows comparisons for compostable vs. non-compostable food serviceware. An example of this would be cold drink cups made from polylactic acid (PLA) vs. polypropylene. A solid majority of the comparisons point in the direction of negative correlation: compostable food service items (composted) in the literature tend to have higher impacts than non-compostable items (disposed or recycled) as a result of their production, either on-farm production of feedstocks or in manufacturing. Although composting generally produces environmental benefits, including water conservation and the potential for reduction in fertilizer use, the quantified benefits of composting food service items tended to be small (sometimes negligible), in part due to the relatively low nutrient value of packages studied. As a result, the offset of production-related impacts due to composting tended to be relatively small.

None of the studies quantified potential benefits associated with an increase in food waste composting that compostable food serviceware may enable. As a result, one would need to have more data on whether use of compostable food serviceware yields a greater quantity of food waste diverted, which in turn could result in higher environmental benefits than the literature revealed. Conversely, none of the studies addressed the negative environmental impacts that could result if non-compostable packaging is commingled with compostable packaging, and the contamination impacts that would result.

A further limitation in this research is the age of the studies. For example, older studies fail to reflect benefits of investments that NatureWorks has made at its PLA biorefinery in Blair, Nebraska. NatureWorks’ PLA is a biobased resin used in production of many compostable products. Figures 2-6 all include (but are not limited to) items made with PLA. Changes in production methods by NatureWorks have reduced the upstream impacts associated with producing PLA. These lower impacts are not reflected in the older studies included in DEQ’s research.

Clearly, the existing literature and pool of analysis is incomplete in its ability to guide policy. But it strongly indicates that “compostability,” as an attribute by itself, does not necessarily guarantee environmental benefits. As with “biobased,” more nuance is needed by both producers and consumers.

Sustainability And Circularity

As momentum grows for increasingly ambitious “Zero Waste” and “Circular Economy” goals and commitments, this research provides three important reminders. First, municipal solid waste is only one small part of the life cycle of materials. In the pursuit of higher order goals, such as reducing pollution and overall resource use, end of life treatments such as composting done well are beneficial, but by themselves, insufficient based on the findings of this literature review.

Second, making decisions that optimize the end-of-life of engineered materials, without considering impacts across the full life cycle, can lead to unintended and potentially negative environmental outcomes. Simply requiring materials to be “compostable” (and composting them) does not guarantee that such materials will result in the lowest overall impacts to the environment, sometimes because of high impacts resulting from the supply chain and manufacturing. Similarly, not all compostable materials are the same — some have lower life cycle impacts, and others have higher impacts.

And third, “circularity” is not a guarantee of sustainability. While recycling and composting may reduce the environmental impacts of materials, they might not address impacts occurring upstream in production of those materials. The literature reviewed in this study showed that compostable and biobased materials can be better than alternatives, but they can also be worse when evaluated using a LCA. Simply requesting these attributes is not the same as assessing environmental impacts.

To achieve higher order goals of environmental protection, packaging options need to be evaluated for impacts across their full life cycle. This will allow designers, buyers, and policymakers to better select options that truly reduce environmental impacts.

The authors all work in the Materials Management program at the Oregon Department of Environmental Quality (DEQ), on a variety of projects that advance Oregon towards achieving its 2050 vision for materials management. David Allaway is a senior policy analyst. Jonathan Rivin is a materials evaluation specialist focused on public procurement. Minal Mistry focuses on business (producer) engagement projects and led DEQ’s attributes research with Franklin Associates. Peter Canepa primarily leads life cycle assessment projects. Links to the series of technical summaries discussed in this article and the project technical report are at BioCycle.net.