Nora Goldstein and Coryanne Mansell

Are you considering adding food waste to your yard trimmings composting operation? Existing composting infrastructure to process leaves, grass, brush and wood chips is often the first to be evaluated when municipalities are seeking outlets for source separated food waste. This may be in response to state and/or city food waste diversion bans, mandates or zero waste goals, climate change mitigation/greenhouse gas emission reductions, or other drivers. The question posed is whether this existing infrastructure is “food waste ready.”

In response to inquiries received from municipal operators considering adding food waste to yard trimmings composting sites, BioCycle and the Center for EcoTechnology (CET) developed a “Community Toolkit: Adding Food Waste to a Yard Trimmings Composting Facility.” The toolkit helps operators determine whether introducing food waste to their facility is a good fit. Topics include: why an operation may want to expand, evaluation of the existing site, best practices for composting food waste, collection and hauling considerations, regulatory requirements, types of food waste, economic considerations, and compost markets. This article is based on excerpts from the toolkit.

Initial Considerations

The majority of municipal yard trimmings composting sites operate on a fairly low technology and minimal staffing basis. Many staff facilities seasonally, e.g., several days a week during the fall leaf collection months, and several days a week in the spring and summer as lawns are mowed, weeds are pulled, and trees are trimmed. Incoming yard trimmings such as leaves and brush may be stockpiled for a few days or longer if there is adequate storage, until a staff person is available to process the materials and put them into windrows or static piles. These piles are turned occasionally unless there are large loads of grass clippings, which require more active initial management.

The majority of municipal yard trimmings composting sites operate on a fairly low technology and minimal staffing basis. Many staff facilities seasonally, e.g., several days a week during the fall leaf collection months, and several days a week in the spring and summer as lawns are mowed, weeds are pulled, and trees are trimmed. Incoming yard trimmings such as leaves and brush may be stockpiled for a few days or longer if there is adequate storage, until a staff person is available to process the materials and put them into windrows or static piles. These piles are turned occasionally unless there are large loads of grass clippings, which require more active initial management.

In larger cities, yard trimmings composting facilities that operate on a year-round basis and receive feedstocks daily, are usually staffed during regular business hours. Due to the amount of organics received, the facilities may operate on a paved surface and be required, for example, to collect and treat leachate and manage storm water in retention ponds.

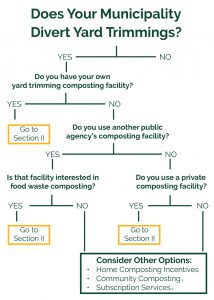

Are these different scales of yard trimmings composting facilities candidates for receiving source separated food waste? The short answer is yes, but under certain conditions. Look at the decision-making tree for current yard trimmings management practices at the top of this column. If you respond “yes” to all the questions, your municipality may be better suited for food waste composting. If you respond no to all the questions, your municipality may need to pursue alternative options for food waste composting, e.g., anaerobic digestion, community composting, expanded home composting programs, etc.

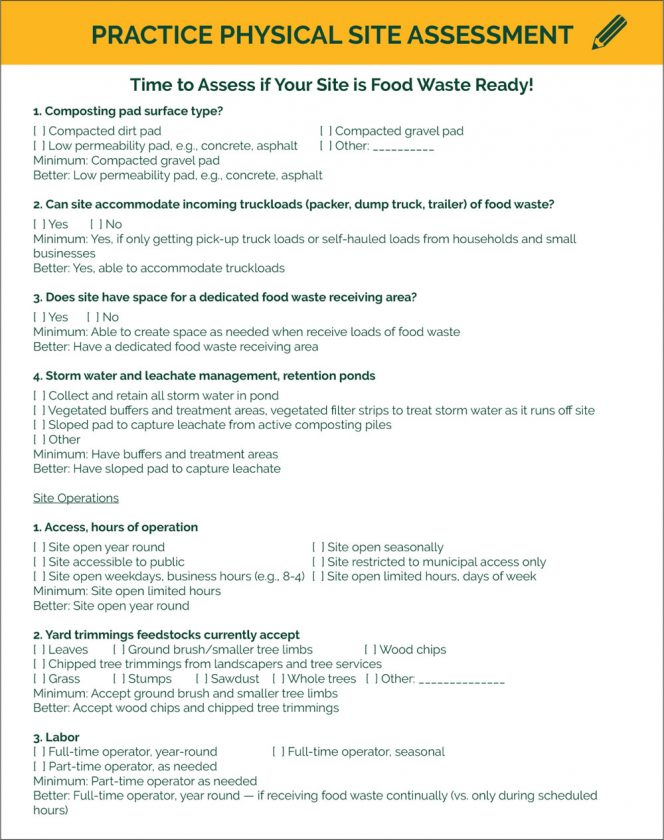

A detailed questionnaire to assess your or your composting contractors’ site readiness for food waste composting is presented in Section II of the document. A “snapshot” of a Practice Physical Site Assessment evaluation to determine if your site is food waste ready is shown here. In all cases, it is imperative to recognize BioCycle’s “Food Waste Composting Ground Rules”.

A detailed questionnaire to assess your or your composting contractors’ site readiness for food waste composting is presented in Section II of the document. A “snapshot” of a Practice Physical Site Assessment evaluation to determine if your site is food waste ready is shown here. In all cases, it is imperative to recognize BioCycle’s “Food Waste Composting Ground Rules”.

What Is Food Waste?

Food waste is a catch-all term for organic residuals that contain a food product — from potato peels to french fries. Many points along the food supply chain create food waste, from farms and food processors to grocery stores and households. The types of food waste feedstock streams accepted for composting directly impact facility design, infrastructure needs, and in some states, permitting category. Regardless of what food waste streams are accepted, operators should consider what type of contaminations they may face.

Unlike leaves, brush, and tree trimmings, food waste is highly putrescible — in short, it does not degrade gracefully. In addition to liquid, odor generation potential is a factor. Some food waste haulers opt to collect food waste more frequently during warm months. Thus, composting facilities that are not open on a daily basis may need to be open and staffed on a more frequent schedule. This helps reduce the odor potential of the loads — especially the liquid fraction. Immediately mixing incoming loads with carbonaceous material is critical, along with getting it into the pile and covered with a layer of wood chips or finished compost.

The types of food waste feedstock streams accepted for composting directly impact facility design, infrastructure needs, and in some states, permitting category.

When food decomposes in a landfill it releases methane, a highly potent greenhouse gas that contributes to global climate change. Redirecting this nutrient-rich material for more beneficial purposes has environmental, economic, and social benefits for your community. To help address this challenge, some states and municipalities have adopted laws or regulations that ban the disposal of food. As a result of these bans, demand for composting infrastructure is likely to increase and many municipal leaf and yard trimmings composting facilities are well positioned to help communities increase their capacity for composting food scraps. The structure of these waste bans and supporting factors are described in a report, “Bans and Beyond,” developed by Center for EcoTechnology and Harvard Law School Food Law and Policy Clinic.

Composting Methods, Recipes

BioCycle and CET developed their toolkit primarily for existing yard trimming composting facilities. Therefore, the question to ask is whether the current composting method is adequate to “meet the demands” of processing food waste.

Food waste and yard trimmings can be composted using any method — windrow, static pile, aerated static pile, or in-vessel. Food waste is high in moisture and nitrogenous, so it is critical to get the initial recipe correct to optimize the carbon: nitrogen (C:N) ratio. Equally critical is process control, avoiding anaerobic pockets, achieving regulatory requirements to meet the required process to further reduce pathogens (covered in Section V, Regulatory Requirements), and maintaining the optimum moisture content.

Food waste is beneficial at yard trimmings and wood residuals composting facilities that need to balance out the C:N ratio. The quantity of food waste to mix in may have to be adjusted depending on the season. For instance, during drought-prone months operators may add moisture-laden food residuals to drier piles to optimize the composting process. During the winter and periods of heavy precipitation, or in the fall with wet leaves, food waste may actually slow down the composting process and potentially cause the compost piles to become anaerobic. The key to year round composting with food waste, therefore, is the recipe, which may need to be adjusted at different times of the year.

Business Of Composting

The minimum equipment required to compost food waste at a full-scale facility is a bucket loader or equivalent.

Section VII of the toolkit is essentially about the “business” of composting food waste at an existing yard trimmings composting facility. Among the business considerations are tipping fees for source separated loads of food waste, impact on facility footprint, labor and equipment requirements and the associated costs, changes in regulatory status and the associated costs, and impact, if any, on compost markets. Climate is also a business consideration, due to the high liquid nature of food waste and the ability to service food waste generators year round. Another factor is whether the state has some type of food waste disposal ban in place or pending, and how that ban is being enforced.

The following rules of thumb are useful when making business decisions:

- Equipment: The minimum equipment required is a bucket loader or equivalent, as operators must mix food waste immediately after it is unloaded with carbonaceous amendment(s).

- Labor: At least one equipment operator must be present to manage the arriving food waste. That person also may need to remove any contamination prior to mixing the load. CET produced “Guidance for Commercial Food Waste Separation” to provide best practices for acceptable handling, storage, and hauling of this material. Operators may refer to this guidance document, and distribute to businesses to encourage best practices and proper separation of food waste to reduce contamination.

- Facility Footprint: Adding food waste to an existing yard trimmings composting facility can be done incrementally on the same footprint, e.g., mixing a certain volume of food waste into the existing operation, or built out as a separate component at the existing site. Because food waste is a fast-acting source of nitrogen made up primarily of water, it has a massive reduction ratio, i.e., it does not add much volume to a pile.

- Process Control: To meet pathogen and vector attraction reduction requirements, operators must take and record pile temperatures. This can be done via wireless sensors and data recording, therefore an employee does not need to be on site. Facilities will need to monitor piles for leachate (too much moisture) and odor generation.

- Compost Markets: Food waste can add more nutrients to the compost, as well as have an impact on salt content. This can be a consideration if the compost is being used in a growing media (e.g., at nurseries), or in green roof mix or other green infrastructure applications where increases in nutrients might be a factor. However, adding food waste does not have an impact on most bulk compost markets, e.g., landscaping, general turf application, etc. Testing the finished compost via laboratory analyses and in-house seed germination tests is recommended (in some states, lab analyses are required).

Compost markets include engineered soils manufactured for bioswales, green roof media, and other green infrastructure applications.

Good Neighbor Practices

When making any change to facility operations, it is critical to “reach out early and often” to site neighbors, elected officials, local and state regulators, and others to explain the changes, and how what you are doing is a benefit to the community. This includes getting involved in food recovery initiatives because your facility may see first-hand how much edible food is in the incoming loads.

Section III, “Best Practices To Compost Food Waste,” includes “good neighbor strategies.”

Here are several tips:

Good neighbor practices are essential to any composting operation, especially when residences are close by.

- Education: Educate your neighbors and the community about the composting process and provide samples of your compost. Provide realistic expectations of site performance, and make it very easy to be contacted (e.g., set up a 24/7 hotline) to register complaints or concerns related to odors, truck traffic, etc.

- Have A Data-Driven Complaint Response Plan: Utilize weather station equipment to record wind direction and speed. Observe weather patterns over the course of the day, e.g., temperature inversions when the layer of cool air at the surface is overlain by a layer of warmer air, which may cause odorous emissions to stay close to the ground as the air moves, increasing potential for offsite impacts. Use this data when responding to complaints, as it can help explain why a neighbor was impacted, or why the composting facility may not be the source of the odor if the wind was blowing in a different direction.

- Respond to Complaints Quickly and Empathetically: Have a response plan in place, including staff trained in complaint response etiquette and protocol (e.g., not losing their cool, understanding and respecting that people are angry about the odors or truck traffic and fearful of a public health impact). Listen and learn before responding. Bring data that will be helpful in the response. Know the limits of your knowledge.

- Always Be Cooperative: Give all potentially impacted parties, including neighbors, elected officials, and community leaders, full cooperation from day one. You want to be, and should be, held accountable. If a problem occurs and stakeholders have agreed upon an acceptable solution in advance, the composting facility will have an established framework in which to address any current or future problems.

- The new “Community Toolkit: Adding Food Waste to a Yard Trimmings Composting Facility,” evaluates the many factors that ultimately determine if a yard trimmings composting site is food waste-ready. While scale of current operations and types of composting technologies employed inform that determination, never lose sight of the reality that food waste is an organic waste stream that does not degrade gracefully. Operators must act immediately when the load arrives, have plenty of carbonaceous material to mix in, and be vigilant about odor, leachate and contaminant management. For many facilities, the best guidance is to start slow, learn best practices to manage food waste at your facility, and then gradually increase the quantity and types of food waste received.

Food waste and yard trimmings can be composted using any method (aerated static pile shown above). Food waste is high in moisture and nitrogenous, so it is critical to get the initial recipe correct.

Nora Goldstein is Editor of BioCycle CONNECT, The Organics Recycling Authority (BioCycle.net). Coryanne Mansell is a Strategic Services Representative at the Center for EcoTechnology. Development of this “Community Toolkit” material is based upon work supported under a grant by the Rural Utilities Service, United States Department of Agriculture. Any opinions, findings, and conclusions or recommendations expressed in this material are the sole responsibilities of the authors and do not necessarily represent the official views of the Rural Utilities Service.