University of Vermont researchers tested a total of 163 samples from 12 composting facilities in 8 separate plantings from November 2013 to August 2015. Plant injuries were observed.

C. Coker, D. Goossen, J. Kelly, A. Hazelrigg and G. Maia

BioCycle March/April 2016

Phytotoxic herbicide impacts such as the curling and twisting of plant leaves appeared in Summer 2012 in gardens in the Burlington area that had been amended with compost.

Unraveling the maze of persistent herbicides in compost has been the topic of a number of articles in this publication since 2001 (visit biocycle.net) as well as discussed in recent fact sheets available from the US Composting Council. The pesticides in question are Clopyralid (sold in the U.S. as Confront, Stinger, etc.), Picloram (sold in the U.S. as Tordon, Grazon), Aminopyralid (sold in the U.S. as Milestone, ForeFront, etc.), and Aminocyclopyrachlor (sold as Streamline). They are designed to be persistent and systemic against broadleaf weeds — thus earning them the name, persistent herbicides (PHs).

These four products are classified as pyridine carboxylic acid herbicides that act as plant-growth regulators (auxin-mimics). PHs are registered for use in right-of-ways (roadsides, railroads, electric lines), industrial sites, natural areas, pastures and grazed areas. They have appeared in composting facilities that take in grass clippings, hay, straw and manures from grazing animals where these herbicides have been used. PHs do survive the composting process, regardless of composting approach or technology used, and are phytotoxic at very low amounts (1 part per billion [ppb] for aminopyralid and 10 ppb for clopyralid).

While this issue of phytotoxic herbicides in compost first came to light in Spokane, Washington in 2000, the most recent epicenter of the outbreak was in June 2012 at Green Mountain Compost (GMC) in Williston, Vermont. GMC is the composting facility owned and operated by the Chittenden Solid Waste Management District. The episode led to over 600 claims of garden damage from the tainted compost, which led to settling 451 claims at a cost to the District of $211,000. Overall damages including lost sales resulted in hundreds of thousands of dollars of additional expenses.

Composters have become more adept at managing the problem through feedstock characterization, recipe algebra, amendments such as herbicide-binding high carbon wood ash (see sidebar), and conducting on-site bioassays in the form of growth tests to verify that product going to market has no deleterious effects on sensitive test plants. Due to the expense and lack of available labs to analyze composts directly for these pesticides, bioassays can offer a relatively quick and inexpensive way for commercial composters to assess potential damage due to the presence of these pesticides in compost. As a result of a grant from the Vermont Agency of Natural Resources, the University of Vermont (UVM) Plant Diagnostic Clinic (PDC) developed replicated compost bioassays to test a total of 163 samples from 12 composting facilities (in 9 Vermont counties) in 8 separate plantings from November 2013 to August 2015. Compost producers and sample identification were kept confidential throughout the course of the study.

The University of Vermont Plant Diagnostic Clinic developed replicated compost bioassays to test a total of 163 samples from 12 composting facilities.

Methods And Parameters Measured

Compost samples were obtained from piles that the composter labeled as “finished compost” or “feedstock.” (These feedstocks were mostly manures and bedding composters wanted tested for PH contamination.) Samples of compost amended with high carbon wood ash (HCWA) were also accepted for testing and were noted. From each compost production facility, between one and 18 composite samples were analyzed during the course of the study. Composite samples consisted of 15 subsamples mixed together. A single sample (1 gallon) from each pile or windrow was sent to the UVM-PDC. Table 1 shows the types and total of compost (as indicated by the composter) samples tested at UVM-PDC.

All compost samples and positive controls were mixed 50:50 with a germinating mix. Bioassays included planting of 3 indicator plants — red clover, fava beans and oats.

Compost analyses were conducted in two parts. The laboratory analysis consisted of measuring pH, electric conductivity (EC) and Compost Maturity Index (using Solvita™ test kits). These tests were done in order to rule out phytotoxic effects from high/low pH, high salts and/or immature/unstable composts. Greenhouse compost bioassays visually measured the auxinic herbicide injury using a scoring system developed by Woods End Research Laboratories, Inc. Bioassays included planting of 3 indicator plant species replicated twice at each planting. All compost samples were mixed 50:50 with a germinating mix which did not contain any compost (Fafard™ Germinating Mix). The positive control was also diluted 50:50 in the same potting mix and the negative control was the Fafard alone.

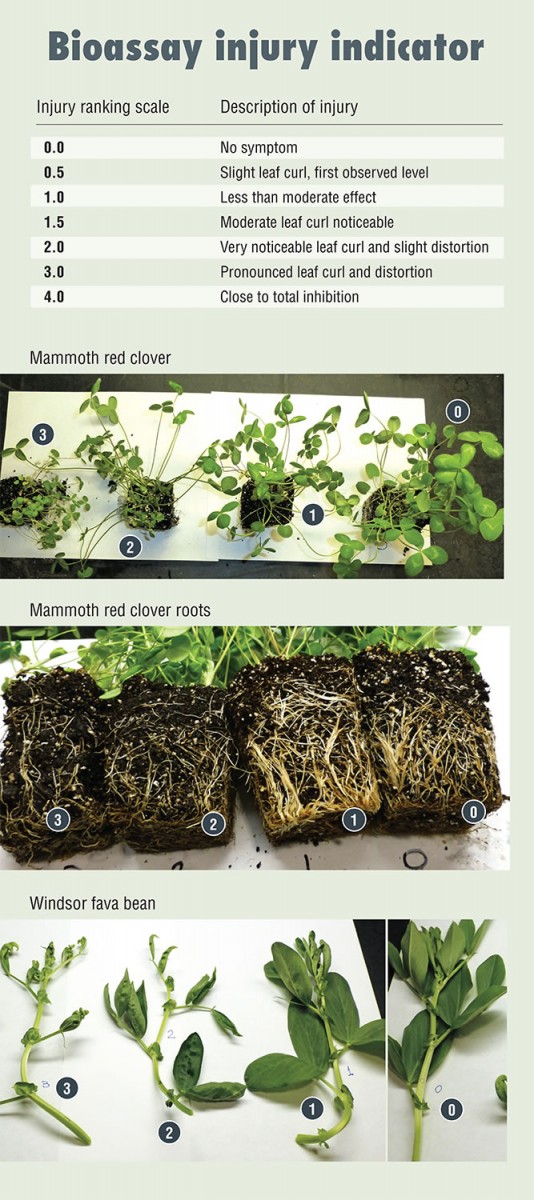

The test procedure for measuring auxinic herbicide injury used, as indicator plants, Mammoth red clover, Windsor fava beans, and Streaker Hulless oats. Initially, sunflower was also used but it proved to be difficult to rate and to discern damage as compared to controls. This indicator plant was later replaced by oats. Each compost sample was mixed 1:1 on a volume-basis with a non-compost based media (Fafard Mix). The injury indicator number (0-4, with 0.5 increments) was based on a visual ranking system of injury to the three indicator plant species.

Each sample was replicated twice for each species with controls of the same species planted in the straight non-compost based media. A twice-replicated positive control was used for each planting. The control was supplied by Chittenden Solid Waste District and had tested at 4.5 ppb aminopyralid (actual amount may be in the 2 ppb range after retesting) by dry weight. In the bioassays the rating of the positive control was variable depending on the planting and showed an injury ranging from 1 to 3 on red clover and 0 to 3 on fava beans.

The final ranking numbers reflected the average injury rating on the red clover seedlings and fava beans after 4 weeks. Oats were included as a negative control since aminopyralid should have no effect on grasses. Injury was assessed using the Woods End Lab rating scale shown in Table 2.

Results

The Chittenden Solid Waste District’s positive control was used as the only positive control throughout all bioassay studies and was stored at 5°C between studies. At the first planting, the positive control was analyzed for pH, EC and maturity index (MI). Thereafter, these parameters were analyzed at random times and did not occur at all plantings. The negative control (Fafard Super Fine Germinating Mix) was also analyzed at the first (pH= 5.46; EC= 0.65) planting and last planting (pH=5.75; EC= 0.32 ). The negative control for each planting always had an auxinic injury rating of 0.

Tables 3, 4 and 5 summarize the findings for Auxinic Injury Ratings on Red Clover (RC) and Fava Beans (FB) compared to the values obtained for the Positive controls, on the same host plants, at each planting. Samples were divided into “Finished” Compost,” “Feedstock” and “HCWA” amended.

Table 3 shows that 21 percent of all the RC planted in “Finished Compost” (not amended with HCWA and not containing Feedstock) showed symptoms/injury ratings greater than or equal to the injury ratings observed for the respective positive controls for each of the 8 plantings during this study. As for the FB, 13 percent of those planted in finished compost showed injury greater than the respective positive control at each planting.

Feedstock samples were not submitted during planting 8. Table 4 shows that 59 percent of all the RC planted in samples labeled “Feedstock” showed symptoms/injury ratings greater than or equal to the injury ratings observed for the respective positive controls at each planting. As for the FB, 44 percent of those planted in feedstock showed injury greater than the positive control at each planting. Two RC and one FB did not germinate during plantings 2 and 3.

Samples amended with HCWA were only submitted during plantings 6, 7 and 8 of the UVM-PDC study. Table 5 shows that 13 percent of all the RC planted in samples amended with HCWA showed symptoms/injury ratings greater than or equal to the injury ratings observed for the respective positive controls at each planting. This may have been due to the possibility that the HCWA did not completely bind all the persistent herbicides. In planting 6, UVM-PDC did not feel confident of the positive control injury rating (0.25) since all the other plantings were at least injury level of 1.0 or greater. As for the FB, 0 (none) of those planted in samples amended with HCWA showed injury greater than the positive control at each planting.

Discussion

Dan Goossen, the manager of Green Mountain Compost who has been in the center of this storm since 2012, offered a telling perspective of UVM-PDC’s two-year trials: “In my view, the findings are pretty conclusive: Compost samples submitted from every composter in the state produced growth deformities in clover and fava bean plants equal to or greater than the level of deformity seen in our positive control — an archived, known aminopyralid-tainted compost from our incident in 2012. The assumption then is that there are sufficient levels of aminopyralid (more than 0.5 ppb), clopyralid (more than 10 ppb), or related compounds in essentially all composting facilities in the state that receive any quantity of commercial manure and/or food residuals — the two confirmed sources of measurable persistent herbicides in GMC feedstocks back in 2012 to show auxinic effects on sensitive broadleaf crops.

“In addition, 21 percent of in the red clover grown in the finished compost samples showed signs of equal or more severe damage than the positive controls. This is something we’ve known for a while now and which I share every time I’m asked, but we haven’t been able to point to anything concrete to back it up until now. And this is just in Vermont where usage of these materials is presumably far less than some other regions of the country where the herbicides are more commonly used, and on much larger tracts of land. Fortunately, here in Vermont, all of the composters are taking preventative measures to avoid what happened at GMC in 2012.“

Observes Ann Hazelrigg, the lead researcher at UVM-PDC: “These test results indicate the bioassays can be a quick and inexpensive way to assess toxicity levels compared with a known positive control. It was fairly easy to separate and rate the plants according to their damage. These tests could be reliably performed by a composter to indicate PH issues, however, having a known positive control for comparison would be very helpful.”

One conclusion that can be drawn from this recent UVM-PDC study is that this issue of persistent herbicides affecting compost quality is not restricted to “one-off” events at single composting facilities. As noted in an earlier article on this subject in BioCycle, some of these herbicides are showing up in grains, vegetables and foods made from these agricultural crops in addition to the animal manures and beddings and in yard trimmings. It is entirely possible that many commercial composts have the chronic problem of low levels of PHs that may, or may not, show up as a distinguishable problem.

Craig Coker (ccoker@jgpress.com) is a Senior Editor at BioCycle and author of several articles and fact sheets on persistent herbicides in composts. Dan Goossen (Dan@greenmountaincompost.com) is Manager of Green Mountain Compost in Williston, VT. Josh Kelly (josh.kelly@vermont.gov) is the Materials Management Section Chief for the Agency of Natural Resources in the VT Dept. of Environmental Conservation. Ann Hazelrigg, Ph.D. (Ann.Hazelrigg@uvm.edu) and Gabriela Maia, M.S. (gsmaia@uvm.edu) are Plant Pathologists with the University of Vermont Extension.