The U.S. EPA’s Landfill Methane Outreach Program (LMOP) released a new report, “An Overview Of Renewable Natural Gas From Biogas,” in July to provide biogas stakeholders and other interested parties with a resource to promote and potentially assist in the development of renewable natural gas (RNG) projects. The document summarizes operational RNG projects in the U.S. at landfills and anaerobic digesters, and the potential for growth. Technical information on how raw biogas is upgraded into RNG and ultimately delivered and used by consumers is included, along with a discussion about barriers, policies and incentives related to RNG project development. The following excerpts provide a flavor of the report’s content:

Carbon Intensity: When fossil natural gas is replaced by RNG, the resulting GHG emission reductions provide a climate benefit. One way to characterize the climate benefit of a fuel is to determine its “carbon intensity” (CI) or “carbon footprint” based on a complete life cycle assessment that estimates the GHG emissions associated with producing and consuming the fuel. The California Air Resources Board (CARB) calculates the CI of renewable fuels as part of its Low Carbon Fuel Standard (LCFS). A table in the report shows CARB’s CI Ranges of Fossil and Renewable Vehicle Fuels (March 2020). Compressed RNG produced from the following sources, and the average CIs (g CO2e/MJ) are: Landfill gas: 46; Digested manure: -271; Wastewater AD: 30; Food and green waste (stand-alone digester): -11.

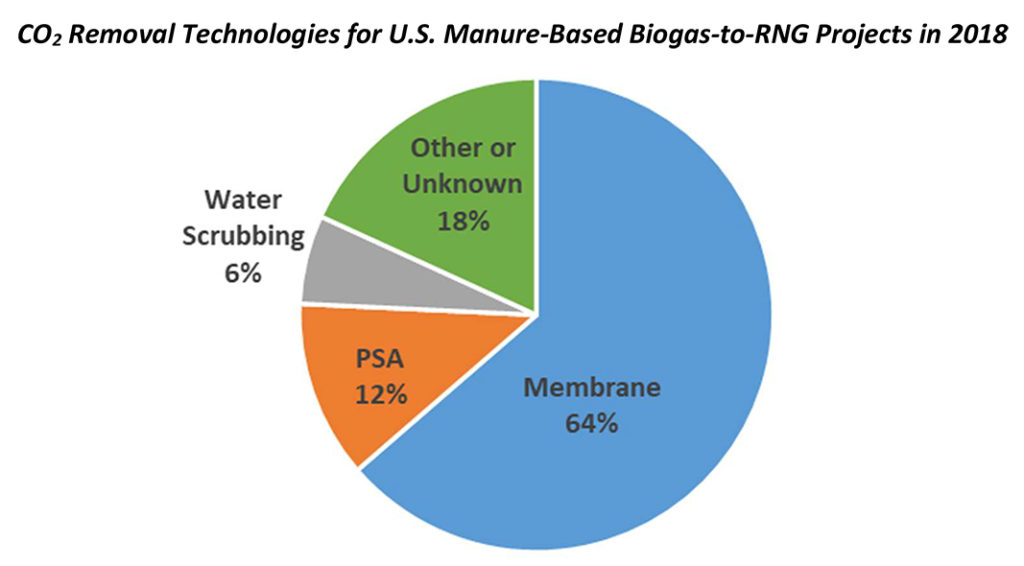

Carbon Dioxide Removal: Based on 2018 data in Argonne National Laboratory’s database of RNG projects, the CO2 removal technology distribution for RNG projects at landfills in the U.S. was solvent scrubbing (27%); membrane systems (24%); pressure swing adsorption (PSA, 10%); and membranes and PSA (8%) used in combination. The balance used water scrubbing or an unknown technology. For manure-based AD biogas-to-RNG projects in the U.S. in 2018, the breakdown is: membrane systems (64%); PSA (12%); and water scrubbing (6%). The balance uses another technology.

Technical and Economic Barriers: Upgrading raw biogas to RNG requires meeting numerous gas quality specifications, which can vary by state or pipeline system and can be difficult to achieve cost-effectively depending on the biogas source. Additionally, utilities may have the misconception that RNG is not as clean as, or is somehow lower in quality than, fossil natural gas. The report describes the nature of each barrier in detail, with solutions to overcome them. The two main economic barriers to producing RNG are the capital and operating costs associated with capturing and cleaning biogas into RNG, relative to the current low price of fossil natural gas, and the cost of delivering RNG to customers, often by building a pipeline interconnection or investing in equipment to deliver the RNG another way.