Top: Food waste, collected in BPI certified compostable Natur-Bag liners, is unloaded at Better Earth Composting in Peoria, IL.

Nora Goldstein and Craig Coker

The US Composting Council (USCC) released “Compostable Products: A Primer for Compost Manufacturers” on June 11, 2021. Authored by BioCycle Associates (BioCycle Connect, LLC’s consulting division), the Primer is part of a virtual “conference” on compostable products that consists of two educational workshops, June 17 and 24, and a Summit on July 15. The workshops delve into the science, history, current status, testing and labeling of compostables; the Summit features a panel of experienced compost manufacturers and will explore the key question, “should I accept compostable products at my facility,” and what are the consequences of deciding one way or another.

The US Composting Council (USCC) released “Compostable Products: A Primer for Compost Manufacturers” on June 11, 2021. Authored by BioCycle Associates (BioCycle Connect, LLC’s consulting division), the Primer is part of a virtual “conference” on compostable products that consists of two educational workshops, June 17 and 24, and a Summit on July 15. The workshops delve into the science, history, current status, testing and labeling of compostables; the Summit features a panel of experienced compost manufacturers and will explore the key question, “should I accept compostable products at my facility,” and what are the consequences of deciding one way or another.

The Primer updates a 2011 USCC document, “Compostable Plastics 101.” As noted in the introduction, a growing focus over the past 10 years has been on finding alternatives to single-use plastic packaging due in large part to global concerns about marine plastic pollution, and the unknown impact of microplastics in terrestrial ecosystems, especially agricultural soils and food systems. Global consumer products companies have made commitments, as part of initiatives to transition packaging from the make-take-waste linear model to a circular economy model, where the plastic does not become pollution but is instead recirculated as a valuable commodity. For example, signatories of the U.S. Plastics Pact are some of the world’s largest beverage and consumer packaged goods (CPG) companies, and they commit to only using packaging that is 100 percent reusable, recyclable or compostable by 2025.

Lawmakers are also tuning into consumers’ concerns. A growing number of municipal and state governments are considering or passing single-use plastic packaging laws, many of which designate compostable packaging as an acceptable alternative.

At the same time, the demand for composting facilities to accept food scraps, let alone compostable products, far exceeds the number in the U.S. that accept them. In 2018, BioCycle conducted a survey of full-scale composting facilities that process food waste. BioCycle defines a full-scale facility as a municipal or commercial facility equipped to receive and process organic waste streams arriving by truckload volumes from generators and haulers on a year-round basis. The survey identified 185 full-scale food waste composting facilities (<4% of the more than 4,700 composting facilities operating in the U.S., most of which accept yard trimmings only). Out of the 103 who answered the question about feedstocks accepted, 61 responded that they accept compostable paper products and 49 responded that they accept certified compostable plastic products.

The Primer has six sections. Section I is titled, “Compostable Products — What Does That Mean?”; Sections II-V cover standards, certifications, regulations and labeling, and bioplastic resins, respectively. Section VI, “Current Landscape For Compostable Products,” looks at some of the challenges related to compost manufacturer acceptance of compostable products. An Appendix defines the types of biopolymers. A separate document posted on the Compost Research & Education Foundation website is a review of the scientific literature on compostable plastics. It is divided into three topic areas:

- Formation and fate in the environment of microplastics derived from compostable bioplastics under industrial-scale composting conditions.

- Factors that optimize the disintegration and biodegradation of compostable bioplastics during industrial-scale composting, including additives.

- Analysis and/or comparison of biodegradation under anaerobic and aerobic conditions.

This article highlights some of the findings explained in the Compostable Products Primer. The document is available on the USCC website.

What Does Compostable Mean?

Compostable products in the context of this document are limited to a discussion of products that are utilized to:

- Physically capture and transport source separated organics, i.e., bags

- Package or label (e.g., produce stickers) foods

- Serve food or contain food for carryout, e.g., cups, straws, utensils, bowls, clamshells

Compostable product formats fall into two basic categories — paper/fiber and plastics. A third format is a “hybrid” of the two, e.g., fiber packaging coated with bioplastic.

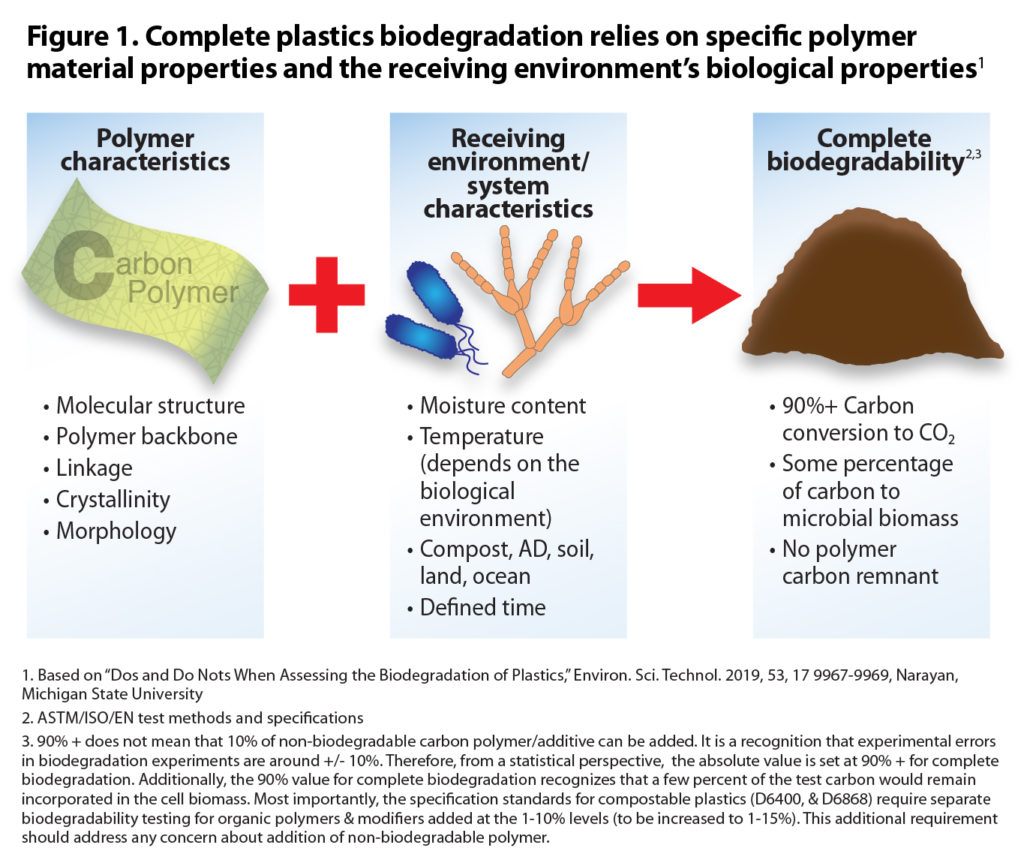

Terminology for compostable plastics is confusing for a host of reasons, starting with the terms “biodegradable” and “compostable.” The following rule of thumb is a useful guideline: Not all biodegradable products are compostable, but all compostable products (assuming they meet existing standards) are completely biodegradable, i.e., achieve 90+ percent conversion of carbon to carbon dioxide by microbial utilization.

The word “biodegradable” in the context of whether it is or is not compostable takes a bit of unpacking (Figure 1). A paper, “Dos and Do Nots When Assessing the Biodegradation of Plastics,” published in Environmental Science & Technology (ES&T), provides a straight forward explanation (Zumstein, et. al, 2019). “It is crucial to recognize that the biodegradability of a plastic is entirely disconnected from the origin of the carbon in the plastic: while a biobased plastic might be nonbiodegradable, plastics based on fossil carbon may readily biodegrade or vice versa,” explain the authors. “Studies that … question biodegradability of certified biodegradable plastics based on experiments in receiving environments other than the one for which the plastic is certified biodegradable ignore the fact that plastic biodegradability is not only a material property but also largely depends on the properties of the receiving environment.”

Dr. Ramani Narayan of Michigan State University, a coauthor of the ES&T paper, provides further context: “Bioplastics is a generic term that includes both ‘biobased’ and ‘biodegradable-compostable’ plastics. Biobased refers to a polymer/plastic in which the carbon, in part or whole, comes from renewable plant-biomass resources. Biodegradable refers to end-of-life in which the plastic/polymer carbon is completely converted to carbon dioxide by microbial metabolism. Biodegradability is a system property and the receiving biological environment (soil, compost, land, ocean, temperature, humidity) needs to be identified.”

Dr. Ramani Narayan of Michigan State University, a coauthor of the ES&T paper, provides further context: “Bioplastics is a generic term that includes both ‘biobased’ and ‘biodegradable-compostable’ plastics. Biobased refers to a polymer/plastic in which the carbon, in part or whole, comes from renewable plant-biomass resources. Biodegradable refers to end-of-life in which the plastic/polymer carbon is completely converted to carbon dioxide by microbial metabolism. Biodegradability is a system property and the receiving biological environment (soil, compost, land, ocean, temperature, humidity) needs to be identified.”

Home-Compostable Certification

The Primer provides an update on U.S. and international compostability standards and certifications. There has been movement on establishing a standard and certification for home compostability. ASTM International Committee D20 continues to discuss the need for standards for backyard or “home” composting. Its proposed method has evolved over the years and is currently focusing on a determination of disintegration in backyard composting.

The proposed standard is under the jurisdiction of Subcommittee D20.96 on Environmentally Degradable Plastics and Biobased Products, which also developed the ASTM D6400 and D6868 standards used to certify compostable plastics. It will contain performance requirements for “home compostability,” requiring that products biodegrade within a certain time frame. After a material is tested by an independent laboratory and approved as “home compostable,” a logo could be printed on the package for consumers. The Biodegradable Products Institute (BPI) is also conducting a scientific review of home composting conditions in the U.S. in an effort to determine appropriate time frames and temperatures for a standardized test and specification.

Products currently sold as “home compostable” in the U.S. often use the “OK compost HOME” certification offered by Austria’s certifier of compostable packaging, TÜV AUSTRIA’s OK (Figure 2). TÜV AUSTRIA bases its home compostable test mainly on adaptations to the commercial compostability tests, doubling the time frame and lowering the temperatures. An Australian standard called AS 5810, entitled “Biodegradable plastics suitable for home composting” is similar (UrthPact, 2020). Both require disintegration in six months, and biodegradation and compost formation in 12 months.

Products currently sold as “home compostable” in the U.S. often use the “OK compost HOME” certification offered by Austria’s certifier of compostable packaging, TÜV AUSTRIA’s OK (Figure 2). TÜV AUSTRIA bases its home compostable test mainly on adaptations to the commercial compostability tests, doubling the time frame and lowering the temperatures. An Australian standard called AS 5810, entitled “Biodegradable plastics suitable for home composting” is similar (UrthPact, 2020). Both require disintegration in six months, and biodegradation and compost formation in 12 months.

Field Verification

One challenge identified in the USCC’s Compostable Plastics 101 — refinement of the ASTM standards — has evolved, with a specific focus on the field verification step. Since the standards were adopted in the 1990s, an increasing number of compost manufacturers have shortened their processing times to as little as 45 days for active composting and curing, with a range of 60 to 120 days from start to finish being more typical. Part of the challenge in determining if certified compostable products will break down is due to this variability in processing time frames and conditions at commercial composting facilities (which makes it challenging to verify and update the ASTM standards). It is also worth noting that shortened composting times may not result in a fully matured, though still marketable, compost product.

The ASTM standard for disintegration is 12 weeks or 84 to 90 days, which on face value is out of sync with shorter time frames for composting. However, that time frame was set in the ASTM ISR study (ISR, 1996) based on a comparison to <60-day field/full-scale tests because it was more conservative (e.g., harder to pass than the full-scale test), and would avoid false positives. In other words, the study found that items failing the lab/pilot scale were still passing in the more aggressive time frames and conditions in the field/full-scale tests, which is preferable to having products pass the lab/pilot scale and fail in the full-scale facility, which would be a false positive.

The same sample kit of certified compostable products (example in left inset) is provided to all compost manufacturers for field testing. Mesh bags with the products can be buried in a windrow or static pile (right inset) as it is being built. Contents of mesh bag mid-way through the composting process (background).

Biodegradation is a process (not visible to the human eye) where microorganisms consume the organic carbon and convert it to carbon dioxide, water vapor and humus. It cannot be measured in a field test, but instead is determined by a laboratory test. By comparison, disintegration is a visual and physical breakdown that can be measured in a field test. The maximum time frame for biodegradation in the ASTM D6400/D6868 standard for industrial compostability is 180 days.

Little data is publicly available to know how much organic carbon from a compostable product may still remain before the compost leaves facilities. In addition, it would be nearly impossible to know whether the carbon detected came from a compostable product versus a conventional plastic contaminant. The 180-day time frame for biodegradation is commonly confused with the 12 week/84-day time frame for disintegration, and is cited by some as a reason why the ASTM standards are out of sync with the operational requirements of composters.

Compost Manufacturer Acceptance

It is anticipated that in this decade, consumer packaged goods will increasingly utilize compostable alternatives for their packaging. Synchronizing introduction of these products with capacity and willingness of compost manufacturers to accept them is necessary. The gap between the number and types of compostable products being introduced into the marketplace and the number of compost manufacturers willing and able to accept those products is significant. Compost manufacturers — those accepting food scraps and those that are not — are being approached regularly about receiving compostable products.

Those already accepting compostable packaging — primarily along with food scraps — are struggling with contamination from lookalike products. Some note that when a consumer or food service worker sees a certified compostable bag or cup in the organics bin, they assume that any bag or cup can go in, whether compostable or not.

This paper, the USCC virtual workshops and Summit, and a decision-making guide for compost manufacturers on acceptance of compostable packaging (to be released in a beta-test form at the Summit), are designed to help compost manufacturers navigate this complex landscape.

Nora Goldstein and Craig Coker are Editor and Senior Editor, respectively, of BioCycle CONNECT and associates of BioCycle Associates. Craig Coker also is a Principal in the firm Coker Composting & Consulting, near Roanoke, VA.