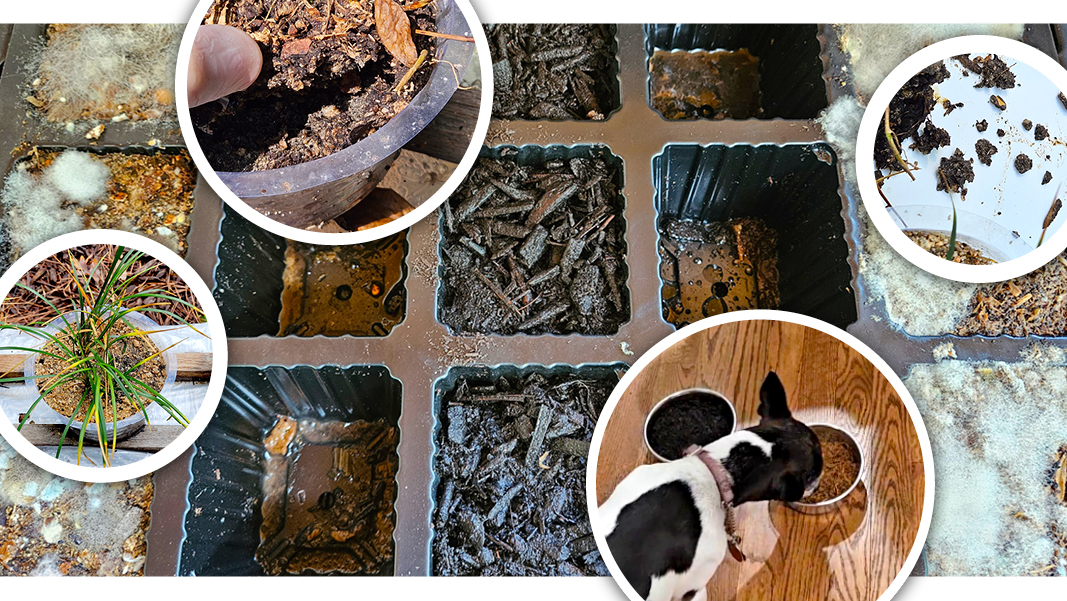

Top: The author prepared and executed various tests to examine how the dehydrated food from a kitchen composter compared to actual compost. Photos by Ron Alexander

Ron Alexander

The commercial composting industry in the United States goes back to the late 1970s when biosolids composting facilities started operating following the collaborative composting research completed by the U.S. Department of Agriculture (USDA) and the U.S. Environmental Protection Agency (EPA). Much of this landmark research is still the backbone of the regulation and “best management practices” used in our industry today. Yard trimmings composting started and greatly expanded during the late 1980s and 1990s, due in large part to state bans on landfill disposal of leaves, grass and brush. And all the while, manure composting continued to expand.

Today, the next commercial composting frontier is wasted and inedible food as feedstock. BioCycle’s 2023 Nationwide Survey: Full-Scale Food Waste Composting Infrastructure in the U.S. surveyed 200 facilities. Recovering and recycling food is incredibly important as our population continues to expand, requiring more food to be used to feed humans and the animals raised for human consumption. Further, disposal of food waste in landfills generates methane which contributes to climate change. Whether recovering food for people or animal feed or processing it to generate energy and/or improve soil quality … it’s all good and it’s all important for the planet and its inhabitants. Rescuing food from the landfill, however, has its challenges, the most important ones probably being collection, and its related costs, inert contamination, and proper processing, as it can easily attract vectors and generate odor.

Commercial composting is a well understood science and manufacturing process today. The microbe-driven exothermic process requires the proper feedstocks (carbon and nitrogen in the proper amounts), oxygen, water, and time. As many of us “lifers” in the industry know — having witnessed some very expensive commercial composting failures — real composting takes months to produce a stable and mature product which is versatile, efficacious and easy to use. And in real composting, heat is generated by the microbes — a sign of biologic degradation — not an outside source.

Food Waste Dehydration

Despite the documented benefits of food recovery and recycling, its growth in the U.S. has been slow (somewhat pragmatic), since managing this highly putrescible feedstock requires proper infrastructure and training. Some states such as California, Vermont, Massachusetts, and New York, have enacted policies embracing food recovery and recycling. The infrastructure required to manage both recovered food (still edible) and food waste is being established. To better manage food waste handling and transport, new technologies, including electric food dehydrators (often incorrectly referred to as “composters”) have been developed.

Commercial food dehydration units were first installed almost 10 years ago in Las Vegas, as I remember evaluating the product for a client interested in utilizing it (test data in Table 1). As reported by BioCycle on multiple occasions, food waste dehydrators show promise for restaurants, food wholesalers, etc., reducing its volume, moisture content, and odor. So, it should be no surprise that these units have been shrunk down to sizes that can be used by homeowners. And for homeowners looking to reduce the ick factor of gathering their food scraps, they can be a great tool.

The systems can reduce the volume of food waste by up to 90%, using an outside heat source, as much food waste possesses a great deal of moisture. The dehydration units use temperatures ranging from approximately 165° to 275° F for a 4-to-20-hour timeframe, with the resulting material having under 10% moisture content. Some technologies suggest adding their microbe or enzyme packages. However, it is not realistic to believe that added microbes are effective at accelerating biological degradation and stabilization, as they are attempting to survive in the hostile environment created within the systems, i.e., high temperatures and low moisture content. Further, adding a small amount of enzymes for a treatment period of 4-to-20-hours is also unlikely to significantly affect biological degradation.

What Is And What Is Not Compost

Note that a defining characteristic of a quality compost product is that microbial decomposition occurs for a long enough period of time that a significant reduction in volatile solids occurs (illustrating biologic carbon stabilization), thereby assuring that vector attraction of the material is permanently reduced so that the finished products, at an appropriate moisture content, do not attract insects or animals or easily regrow pathogens. This research dates back to the USDA Agricultural Research Laboratory in Beltsville, Maryland in the late 1970s. Further, the USEPA 40CFR Part 503 biosolids regulations require a minimum of 38% volatile solids mass reduction to meet vector attraction reduction. The Ohio State University’s Compost Operator Education Course Book suggests that volatile solids loss during composting “ranges from 30% for leaves to up to 90% for food wastes.”

In 2018, the American Association of Plant Food Control Officials (AAPFCO) approved a new definition for compost that makes it clear what compost is (and is not):

Compost – is the product manufactured through the controlled aerobic, biological decomposition of biodegradable materials. The product has undergone mesophilic and thermophilic temperatures, which significantly reduces the viability of pathogens and weed seeds, and stabilizes the carbon, such that it is beneficial to plant growth. Compost is typically used as a soil amendment, but may also contribute plant nutrients. (AAPFCO Definition – Official 2018)

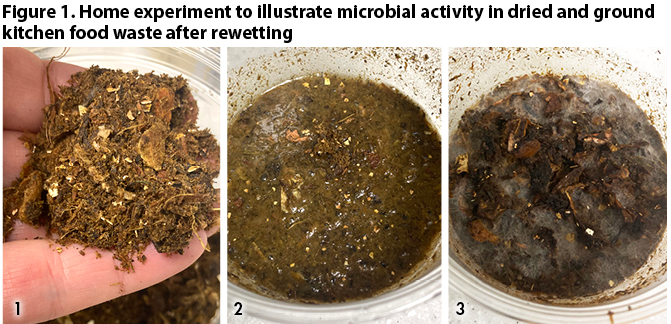

Having this definition is a critically important framework as manufacturers and marketers of new technologies to process food waste either claim or imply that the output from food waste dehydrators is compost or can be used in the same way as compost. In a BioCycle CONNECT column in March 2023, Dr. Sally Brown noted, “these appliances take the highly putrescible (ready to rot) food waste and stabilize it by removing the moisture. Without the water, no microbe can decompose the stuff. The drying removes the water and also concentrates the salts. When you take this dried food waste and put water back into it (Figure 1), the microbes are able to step right up and resume the decomposition process. The yuck comes right back” (Brown, 2023). Therefore, the dehydrated food waste is simply “shelf” stable, not properly biologically stable.

Dried and ground food waste (1), Rewetted material (2), Mold resulting from microbial activity (3). Photos by Sally Brown

Other data has been published illustrating that the dehydrated material is not compost or appropriate for immediate usage, and realistically requires further processing and significant curing (stabilization and maturation) for efficacious application. For example, research recently completed at the Universiti Brunei (in Darussalam, Brunei) found that materials produced during their home electric “composter” trials were “still found to be immature and would require additional curing. Their research also indicated the presence of a substantial level of phytotoxins within the samples, even after four weeks of curing” (Azis et al., 2023).

As reported in BioCycle in 2011, Loyola Marymount University completed trials processing its dining hall residuals using a commercial scale dehydration unit (Rasmussen et al., 2011). Since the manufacturer had suggested that the resulting product could be used as a soil amendment or mulch additive for commercial and home garden applications, the University initiated a research project. What they found was where the “unprocessed dehydrated food waste” was blended into mulch, that mulch “experienced a steep rise in fungal growth over the first two to three weeks; all three reached high fungus coverage (between 75-100% coverage),” and therefore not suitable for use in campus landscaping operations.

Garden Fundamentals, a science-based gardening group that worked with electric kitchen units, reported that it had “contacted several manufacturers and asked them for proof that they compost. None had any. To be honest they didn’t really understand what composting is” (Pavlis, 2021). Garden Fundamentals further stated that the term “dehydrated food waste byproduct” seems like a good description of the material produced by these units.

A few companies in this market space, such as Mill Industries, have been more academically honest by positioning their “food recycling” units, which are essentially preprocessing systems, while also making household kitchen scraps easier to handle. Further, the company does not refer to its resulting material as “compost” or “dirt,” which can lead to its inappropriate usage. Mill’s contracted field research found that the use of the dehydrated food material directly applied to the soil at various rates led to significant mold generation in the field, as well as attraction of both domesticated (dogs) and wild animals (racoons, skunks, etc.) where the product was utilized, even when incorporated into the soil. Its laboratory research further found that the material achieved minimal volatile solids reduction and required post processing management to allow it to be used as an efficacious soil amendment. While over time the material stabilized and did not inhibit plant growth, the research recommended that the dehydrated food scraps were not suitable for immediate use as a soil amendment but could be if further processed. For that reason, Mill did not position its resulting material as a “compost” or a ready to use soil amendment.

Testing Use Of Dehydrated Outputs

Reviewing this type of existing data and with a concern that calling the material coming out of these electric kitchen dehydrating units “compost” — or calling the units themselves “composters” — would negatively affect the reputation of “real compost” developed over the past 45 years, I both produced and obtained dehydrated food materials and completed a series of simple experiments to evaluate the use of the output as a soil amendment or organic fertilizer. My experiments included measuring mold generation and plant growth trials, as well as having the outputs evaluated by an accredited analytical laboratory. The methodology used and my findings are described below.

Molding: Much of the prior research illustrated that the dehydrated food material was prone to molding. This is a nuisance to an end user, has been shown to kill some plants, and illustrates a low degree of biologic stabilization. To evaluate the use of the material as a fertilizer topdressed in an indoor potting situation, dried and ground output from two electric kitchen units and compost were placed into planting trays, watered and covered to maintain moisture content. On the third day significant mold generation occurred in some of the dehydrated food samples, along with a significant odor. After five days, mold had just about covered both of the dehydrated food samples (Figure 2) and there was so much offensive odor that the experiment had to be moved outside. Outside, the dehydrated food samples attracted flies on an ongoing basis. All of this illustrates significant vector attraction.

Rewetted dehydrated food sample A (1), Rewetted compost (2), Rewetted dehydrated food sample B (3). Photo by Ron Alexander

Photo by Ron Alexander

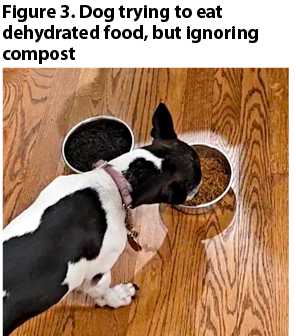

Prior research also illustrated vector attraction of mammals where the dehydrated food was used in field applications. Our simple indoor vector attraction test, using the mammalian species Canis familiaris (the domesticated dog) illustrated that dehydrated food, even without moisturization, attracted an animal (Figure 3) seeking to consume it while ignoring actual compost.

Growth Trials

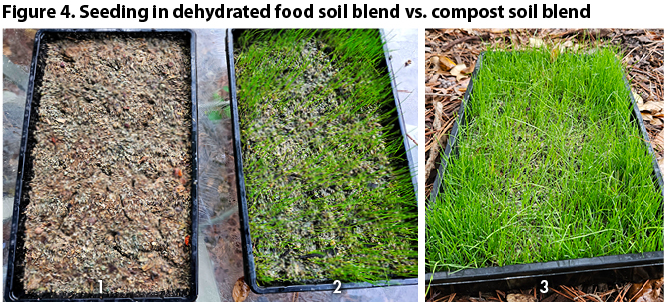

Having completed many compost product (and recycled organic product) development and field research trials over the past four decades, two simple growth trials were set up using a typical compost inclusion rate and a sandy soil. Rye grass was planted in one trial using a 25% inclusion rate of compost or dehydrated food and 75% sandy soil. The treatments were watered but no fertility was applied. As illustrated in Figure 4, there was no germination at all in the dehydrated food-soil blend but the grass flourished in the compost-soil blend. Further, the treatment containing 25% dehydrated food attracted a lot of flies and smaller insects assumed to be gnats or fruit flies, and generated significant odor. After two weeks, the treatment containing dehydrated food material was abandoned, because no seed germination had occurred and there was significant odor generation. It was also noticed that this flat held a lot of water (didn’t appear to drain properly) and the soil surface crusted over (Figure 5).

One week after seeding: Dehydrated food blend (1) , Compost blend (2). Three weeks after, seeding in compost blend featured good coverage and color (3). Photos by Ron Alexander

No seed germination in 25% dehydrated food soil blend (1); Dehydrated food mulch crusting on top of flat and pot (1, 2). Photos by Ron Alexander

In a second trial, Mondo grass was grown in media containing 50% sandy soil, 25% peat moss and 25% compost or one of two dehydrated food products. Two pots of each blend were planted with one of each being topdressed with the same compost or dehydrated output used in the media. The topdressed product would act to provide additional nutrition to the plant (act as a fertilizer). Again, treatments were watered but no fertility was applied. From the start of the trial the pots mulched with the dehydrated food material attracted flies and were slow to accept water. By day five, tip burn was noticed on all three mulched pots, but this was much more significant on the dehydrated food material-treated pots. Over the next week, tip burn and yellowing of leaves increased in the four dehydrated food containing pots, with the mulched pots being the worst (Figure 6). The two compost containing pots accepted and drained water more readily and its leaves possessed better color (Figure 7), as well as had a more robust root system.

Ater 21 days, all pots containing 25% dehydrated food show tip burn (1, 2, 3). Pot also mulched with dehydrated food displayed increased problems (3). Photo by Ron Alexander

Pot containing 25% compost (1), Pot containing 25% compost and mulched (2). Excellent rooting (to bottom of pot) in pot containing 25% compost, plus mulch (3). Photos by Ron Alexander

Photo by Ron Alexander

This trend continued and at day 12 the mulch from the dehydrated food treated pots was removed to see if plant growth would improve. It did not and all dehydrated food treated pots continued to be slow to accept water, then stayed very wet. Moisture was measured with a handheld moisture meter and used to schedule watering. By the end of the trial (day 25), the plants in three of the four pots containing dehydrated food were greatly damaged, with one pot containing plants that were nearly all dead. This 25% inclusion rate and mulched dehydrated food pot stayed excessively waterlogged and contained a significant amount of living insect larvae. Two of four dehydrated food containing pots contained living insect larvae (Figure 8).

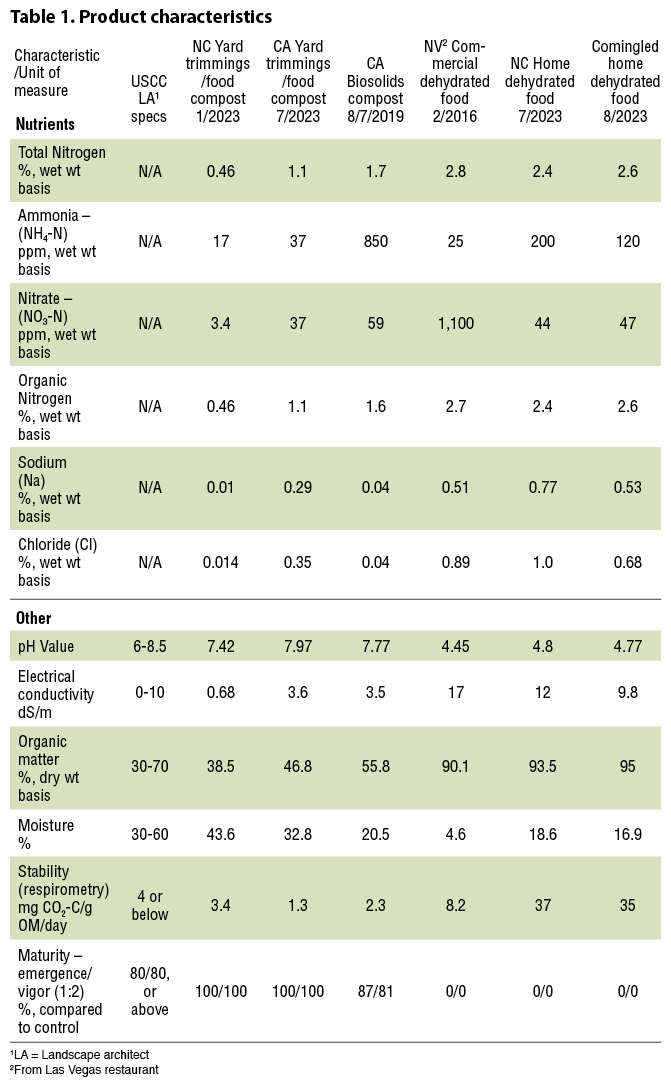

Product Test Data

The two dehydrated food wastes used in the experiments were sent to a lab for product characteristic analysis (Table 1); other composts and a dehydrated food waste from Las Vegas are also included for comparison. The chemical characteristics of the dehydrated food materials will vary based on their input feedstocks, and the same can be said about compost. However, certain characteristics, indicative of the dehydrated food materials — such as a high electrical conductivity, sodium and chloride content, and a very low moisture content and pH — are problematic to their efficacious use as a soil amendment. The sodium and chloride content of the dehydrated food materials is two to three times higher than most yard trimmings/food waste-based composts that I have evaluated in the past. Since these salts are known to be damaging to seeds and seedlings, and commercial composts possessing these high levels of sodium and chloride are not readily available in the U.S. marketplace, additional plant growth research is warranted.

Dehydrated food material’s low pH, high organic matter content, poor stability and maturity ratings are all indications that the food material requires additional biological stabilization before using it as a soil amendment, without having deleterious plant establishment and growth (or other nuisance) effects. The amount of time necessary for appropriate stabilization is unclear, however the materials must be properly oxygenated and moistened to first allow for microbial repopulation before biological stabilization can occur. Further, the high temperatures used in these dehydration units and loss of moisture work to essentially eradicate microbial life in the material. This statement was confirmed by DNA sequencing (through Genome Insights, Hillsborough, NC) of a dehydrated food sample produced by the author, which identified “no measurable (microbial) DNA” in the sample. No microbial DNA = no live microbes = no microbial stabilization.

Dehydrated food material’s low pH, high organic matter content, poor stability and maturity ratings are all indications that the food material requires additional biological stabilization before using it as a soil amendment, without having deleterious plant establishment and growth (or other nuisance) effects. The amount of time necessary for appropriate stabilization is unclear, however the materials must be properly oxygenated and moistened to first allow for microbial repopulation before biological stabilization can occur. Further, the high temperatures used in these dehydration units and loss of moisture work to essentially eradicate microbial life in the material. This statement was confirmed by DNA sequencing (through Genome Insights, Hillsborough, NC) of a dehydrated food sample produced by the author, which identified “no measurable (microbial) DNA” in the sample. No microbial DNA = no live microbes = no microbial stabilization.

The extremely high organic matter content of the dehydrated food materials is an indicator that a reduction in volatile solids hasn’t taken place, an essential characteristic of real compost, and therefore vector attraction reduction has not been achieved. This was illustrated by mold formation, and the attraction of flies and wild animals for the dehydrated food material. It is unclear whether this characteristic also means that there will be more significant regrowth of pathogens in the product. Finally, some field research suggests that use of this material directly from the food waste dehydrator may attract dogs or wild animals looking for food.

Lessons Learned

While the kitchen and commercial food dehydration devices show promise in managing the logistics of food recovery and recycling, as well as reducing the “ick” factor, it does not appear (with few exceptions as discussed above) that nearly enough work has been completed to figure out the management and final disposition of the resulting product. Cavalierly calling the product “compost” (or inferring it is compost by marketing the unit as a “composter”), soil amendment, fertilizer or dirt without completing the due diligence related to its end use is risky and can greatly hurt the reputation of real compost (as well as the food dehydration devices).

My limited field trials also identified negative effects of using the dehydrated food material in soil blends as far as moisture acceptance and drainage, which are problematic in seed germination, plant establishment and growth. All in all, it appears that much more research is required to understand the efficacious end use of the dehydrated food materials. And it certainly appears inappropriate to call the resulting materials produced from these electric dehydration units “compost”, so it is misleading — especially for consumers who would like to make compost at home — to call the technologies “composters.”

The commercial composting industry in the U.S. went through periods where clever technology companies would argue over how fast they could produce compost. All believed that they could outthink the microbes, which can only work as fast as they can work. These technologies and facilities failed while giving the industry a black eye and slowing its overall growth. We now seem to be in a place where another useful technology, this one for food waste preprocessing, may be overpromising what it can deliver, speaking to the need for self-regulation of that industry. If not, the federal government may need to step in to regulate the electric food recycling industry — especially about its claim to be marketing “composters” and producing “compost” — before it damages the reputation of commercially manufactured compost and puts at risk the billions of dollars of public and private infrastructure investment used in its development, not to mention the possible billion dollars of compost sales revenues generated annually (assuming 100 million CY produced/year x $10/CY).

There is no doubt that the dehydrated food material could be further processed at commercial composting or anaerobic digestion facilities and probably be added to backyard composting piles or used in vermiculture (worm food) applications. There is also a likely application as an animal feed additive. However, use of the materials as soil amendments or fertilizers, right out of the dehydration systems, appear to be fraught with nuisance issues (e.g., odor, mold, vector attraction) that require further study.

It should also be mentioned that the commercial composting industry is governed by regulation and its end product is supported by probably over $100 million of university research in the U.S. alone. We have to make sure that in our zeal to better manage food waste that we do not allow unregulated home and commercial food dehydration units (requiring no permitting for operation) to damage the well-established commercial composting industry, which manufactures massive volumes of efficacious soil building products, while reducing methane generation and creating jobs.

References

Azis, F.A., M. Choo, H. Suhaimi and P.E. Abas, Universiti Brunei Darussalam. 2023., The Effect of Initial Carbon to Nitrogen Ratio on Kitchen Waste Composting Maturity. Sustainability, 15(7), 6191.

Brown, S. 2023. Connections: What Is Not Compost. BioCycle CONNECT.

Pavlis, R. 2023. Garden Myths – Learn the truth about gardening, Electric Composters – An Eco Win or Unnecessary Appliance? Garden Fundamentals.

Rasmussen, J. and B. Bergstrom. 2011. Food Waste Diversion at Urban University. BioCycle. Vol. 52, No. 12, p. 34

Ron Alexander is a horticulturist and president of R. Alexander Associates, Inc. (Apex, North Carolina), a company specializing in product and market development for organic recycled products. He is author of ”The Practical Guide to Compost Marketing and Sales” (2nd Edition published by BioCycle) and has over 40 years of experience in compost and recycled organics product development and marketing. Mr. Alexander is an Industry Liaison to AAPFCO (Association of American Plant Food Control Officials) and completed research during his tenure in college and after, working with university researchers and public and private testing laboratories. He thanks the US Composting Council, Soil Control Labs, Nora Goldstein, Dr. Sally Brown and Dr. Geoff Hill with the development of this article.