Top: Concession stands at Moda Center once again offer food selections served using certified compostable products. Photos courtesy Portland Trail Blazers

Nora Goldstein

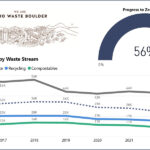

The National Basketball Association’s Portland (Oregon) Trail Blazers blazed the zero waste trail almost 15 years ago, becoming one of the first professional sports teams in the country to implement a food waste composting program. The initiative started in the arena’s suites, and gradually expanded to the entire arena, capturing both back-of-house and front-of-house food waste and certified compostable foodservice ware. Organics diversion was one component of the basketball franchise’s greening commitment, along with recycling, energy and water conservation, use of renewable energy and drought-resistant landscaping. The team helped found the Green Sports Alliance, earned LEED Platinum certification for its arena, Moda Center, and most recently began using reusable beverage cups for alcohol purchases. “We have a goal of achieving zero waste for every event no later than 2030,” notes Brittany Saulsbury, the Portland Trail Blazers’ Sustainability Operations Manager.

The Trail Blazers’ food waste recycling initiative experienced a setback in early 2019, when a group of Oregon composting facilities that accept food waste and compostables signed onto a declaration that they were going “food-only,” no longer accepting compostable packaging and serviceware. Included was Pacific Region Compost, owned by Republic Industries, that was doing the collection and composting for Moda Center. “We were diverting 30 to 40 tons/month of food waste and compostable foodservice ware to Pacific Region Compost during our busy months,” says Saulsbury. “When we had to shift to capturing food only, we stopped diverting from the front-of-house within the venue to only capturing back-of-house material from the food vendors. It definitely hurt our diversion, which dropped to about 10 to 15 tons/month.”

Turning The Tide

Once operations normalized following the COVID-19 pandemic, the Trail Blazers continued composting back-of-house food waste but remained interested and willing to restart the program to capture the front-of-house stream. Around that time, Justin Zeulner — who served as Senior Director of Sustainability and Public Affairs for the Portland Trail Blazers from 1999 to 2014 and oversaw the launch of the arena’s zero waste programs — relocated to Portland. Zeulner had founded The Wave Foundation in 2018 with the purpose of strengthening community health, local economies, and environmental sustainability in the Pacific Northwest by “reducing demand for new materials and related harvesting or extraction of natural resources while promoting waste reduction strategies through source reduction, efficient resource use, sustainable sourcing, recycling, upcycling, composting, and recovery.”

Among The Wave Foundation’s initiatives, working alongside partners like NatureWorks, Natur-Tec, and Eco-Products, was to rekindle a closed loop solution for Portland venues — including Moda Center, the Oregon Convention Center, Portland’5, Portland Expo, Oregon Zoo, and Providence Park — that would capture all food waste along with compostable foodservice ware. “We began organizing discussions with venues, asking if The Wave Foundation could create a solution, would they be interested in participating,” explains Zeulner. “The response was positive. We also approached the solid waste haulers servicing these venues, including WM and Republic, to see if they were open to being part of the solution. Both said no. The composting facilities that had signed onto the declaration to accept food only also did not change their positions.”

Undaunted, Zeulner continued to explore options. During a conversation with DeSantis Landscapes, a local company that installs native landscapes and utilizes compost, Zeulner learned about Annen Bros. Farm in Mt. Angel, Oregon, a large-scale hazelnut grower that has a farm-based composting facility and utilizes the compost it makes in its orchards. He also was introduced to City of Roses Disposal and Recycling (COR), a Portland-based solid waste company with experience in organics recycling. Both Annen Bros. and COR were interested in servicing the collection and composting program.

Collection And Composting Components

A variety of boxes needed to be checked to begin diverting the postconsumer food waste and compostable packaging to Annen Bros. Farm. This included COR applying to Oregon Metro (Metro) for a non-systems license. Metro, the regional government agency that regulates solid waste, requires that all solid waste (including food scraps and other recyclable materials) generated inside the Metro jurisdictional boundary must be transported to a facility that is part of the region’s solid waste system or otherwise authorized under a separate non-system license (NSL). A NSL is a regulatory instrument that allows Metro to monitor the flow of waste and ensure that it is properly managed at approved facilities once it leaves the region. The NSL was issued to COR Disposal and Recycling, explained a Metro representative, and it covers source separated commercial food waste generated within the Metro area that is collected by COR. The NSL does not specify certain businesses that generate commercial food waste thus the venues that COR services are included under the NSL. COR may deliver commercial food waste from other businesses to Annen Bros. in accordance with the NSL requirements.

Metro requires local governments to adopt an ordinance that meets region-wide standards for the separation and collection of food waste from certain food-generating businesses. The program is food only and local government ordinances also require businesses to keep food waste separate from compostable packaging and utensils or other non-food items. If a Metro transfer station receives a load of business food waste that contains compostable packaging, then Metro considers the load to be contaminated and would reject the material from recovery, explained the Metro representative. The contaminated load would instead be sent to a landfill for disposal with other garbage. These requirements led to COR needing a NSL.

Annen Bros. had to get a solid waste registration permit from the Oregon Department of Environmental Quality (DEQ) to process the source separated food scraps and other feedstocks. The farm had been operating its composting facility under a registration with the Oregon Department of Agriculture to process agricultural feedstocks only. “We used to grow hops and would compost the residuals,” says Chase Annen. “In 2010, we installed a Green Mountain Technologies’ concrete aerated composting pad to improve the efficiency of managing the hop waste. Over the years, we stopped growing hops and expanded into growing hazelnuts, but continued to use the pad to compost manure, yard debris, and some tree trimmings. Therefore, we were equipped to compost the food waste and compostable foodservice ware from Moda Center.”

Food waste, compostable foodservice packaging and liner bags tipped at Annen Bros.’s composting facility in Mt. Angel, Oregon. Photos courtesy of Annen Bros. Farm

Zeulner introduced Annen to Carla Castagnero, president of AgRecycle in Pittsburgh, Pennsylvania, who has been collecting and successfully composting food waste and compostable foodservice ware from venues, including the Pittsburgh Pirates ballpark, for many years. Castagnero advised Annen on how to effectively and efficiently process loads from Moda Center. “Every incoming load should be tipped in an area where the operator is able to inspect the materials for contaminants,” explains Castagnero. “There are items that aren’t visible when inspecting loads at the venue, but when spread out on the receiving pad, become evident. I also recommended that once contaminants are removed, the material be blended in a mechanical mixer with amendment to size-reduce the products.”

“We followed Carla’s recommendations and created plenty of space to be able to spread out the incoming load and remove contamination,” adds Annen, who typically does the picking himself. “It usually takes about 30 minutes and involves breaking open the compostable liner bags to inspect the contents. Bags with a lot of contamination are disposed. Typically, we find candy bar wrappers, plastic wrap, warming tray candles, and bottles and cans. In a 10-cubic yard load of material coming in, contamination is less than 0.5 cy.” The Trail Blazers are charged a fee for Annen’s time required to remove contamination. “Chase sends photos of contamination to us, which is very helpful,” notes Saulsbury. “We use the photos to pinpoint where it is coming from and improve our training and processes.”

It typically takes 30 minutes to remove contaminants from an incoming load that is spread out on the receiving pad.

Once sorted, the material is loaded into a feed mixer that slices up the cups and other items into chunks. “I usually add a drier amendment, like leaves, to the mixer as well,” he continues. “Our aerated static piles are usually about 10% food waste by weight. The compostable packaging all disintegrates during our composting process, which can be as long as two months, depending on the quantity of incoming material.” Finished compost is applied to the hazelnut orchards or sold. About 8,000 tons of all feedstocks were composted in 2023.

Reusable Cups

The Trail Blazers utilize certified compostable foodservice ware supplied by Eco-Products. The vendor became an Official Zero Waste Partner in October 2023, with its products being used at all concession stands and premium areas throughout Moda Center. Products include plates, bowls, trays, utensils, cups, and straws. Eco-Products also provides cups for alcoholic beverages for Moda Center’s groundbreaking reusable drinkware program through a partnership with its Novolex® sister company, Waddington North America®. “Our partnership with Eco-Products will support and elevate our goal of only having compostables, recyclables, and reusables at our concession stands,” notes Saulsbury. “All front-of-house collection stations have bins for recyclables, compostables, trash and reusable cups, which were introduced in October 2023. Cups are one of our largest single-use items, which is why we are focusing on those initially for the reuse program. So far, we’ve eliminated 168,000 single-use cups from our waste stream through the program. Our goal is to get to a half-million by the end of the season. We are the first U.S. professional sports venue to introduce reusable cups venue-wide, so it’s a learning experience for all teams.”

She adds that since the launch of the reusable cups, branded Rip City Reuse, they have been seeing a 75% return rate of the cups. “We estimate the other 25% are being taken home by fans. No deposit is charged so we are evaluating options to increase the capture rate.” The reusable cups are collected and sanitized by Bold Reuse, a local women-owned company. The Blazers worked with Bold Reuse during the 2022-2023 season by converting single-use serving boats into reusable trays on the Club level at the arena. The pilot program achieved an 88% average return rate by the end of the season. “Moreover, 95% of the fans who participated in the pilot expressed their desire to see the initiative expanded to encompass additional products and levels within the arena,” notes a Bold Reuse press release. “This resounding support from the Portland community fueled the decision to introduce reusable cups for alcoholic beverages on an arena-wide scale.”

In-House Sorting

ServiceMaster Building Services, a Proud Partner of the Portland Trail Blazers, is contracted to clean the arena after games and other events and to sort bags collected from the front-of-house bins. The cleaning crews do several sweeps of the seating areas; the first crew picks up compostable foodservice ware, the second gathers recyclables, the third collects the reusable cups, and a fourth crew picks up trash.

Bags from the front-of-house collection stations are sorted at Moda Center to remove contamination and capture recoverable items deposited in the wrong bin.

Bags from waste stations are brought to an area at the end of the night where ServiceMaster’s staff sorts through them to recover reusable cups, compostable products and recyclables that ended up in the wrong bin. This ensures waste streams have minimal contamination. Large tables on wheels are currently used to do the sorting; to help recover the compostable products, samples are attached to a board as a visual aid in the sorting area. “The visible Eco-Products logo on the foodservice packaging makes it easier to identify the compostables,” notes Saulsbury, who says when the Blazers reintroduced the front-of-house bins and post-collection bag sorting, the learning curve was steep. A conveyor belt to facilitate the bag sorting process is also being evaluated to improve the efficiency of the sorting process.

“There isn’t a net savings on our trash disposal because of the cost to service the zero waste program,” says Saulsbury. “We are doing it because it is the right thing to do. For COR to haul to Annen Bros., it is not a part of their typical route, so it is more expensive to do than when collected organics with compostable foodservice ware were brought to the Metro transfer station in Portland. If more venues could participate, the fees would go down because more material would be collected and hauled to the composting facility. Being a true zero waste venue is challenging because it depends largely on the local infrastructure available, and we often have to think creatively and work collaboratively to come up with solutions.”

Using a grant from the U.S. Department of Agriculture’s National Institute of Food and Agriculture (NIFA),The Wave Foundation is continuing to work with venues in Portland to identify options for closed-loop solutions. Other initiatives include facilitating donation of surplus edible food from the venues and laying the groundwork to include for-profit sales of food from historically underserved Native, Black, Indigenous, and People of Color (BIPOC), and women producers to large venues, restaurants, and other buyers to create a circular system of production, use, donations, and sales. “For example, Yakama Nation Farms currently wastes second and third cut produce that could be purchased and used by Levy Restaurants — the foodservice vendor for Moda Center and the other Portland public venues,” explains Zeulner. “The goal is to include 60 producers making sales to participating venues within two years. This includes value-added hazelnut products that could be sold at concession stands.”