BioCycle March/April 2018

Boston, Massachusetts: Organics Recyclers Receive Equipment Grants

Under its Solid Waste Master Plan, Massachusetts has a goal to reduce trash by 2 million tons annually by 2020. To assist companies that will turn recyclable materials into new products, compost or a renewable energy source through anaerobic digestion, nearly $1 million in grants were awarded to six companies under the state’s Recycling Business Development Grant (RBDG) program. The Massachusetts Department of Environmental Protection (MassDEP) administers the RBDG grant program, which targets difficult-to-recycle materials, including food with contaminants such as plastic, rubber gloves, and cutlery; wood; and bulky, rigid plastics. This round of grants will fund projects that promote materials recovery and will build the state’s infrastructure to better manage these materials. As a condition of receiving funding, grant recipients commit to meeting tonnage goals over a two-year period.

Two of the grant recipients involving anaerobic digestion (AD) are:

• Ag-Grid Energy, LLC is forming Rockwood Ag-Grid Organics, LLC with Rockwood Farm, a dairy in Granville, to develop an AD facility to codigest manure from the farm’s dairy cows and food materials from off-site sources. Ag-Grid Energy, LLC received $250,000 to purchase a depackaging unit that will enable the facility to accept food contaminated with other materials and separate those materials to produce a high-quality feedstock for the digester. Initially, the facility will be able to accept about 20,000 tons of food material annually, with the potential to increase to 60,000 tons/year over time.

• Waste Management established a Centralized Organics Recycling (CORe) facility in Charlestown that receives food waste containing some inorganic material, such as plastic bags and gloves, and processes it to produce a slurry suitable as a a feedstock for AD facilities. Waste Management received up to $100,000 for a blending and storage tank, along with associated piping and pumping infrastructure, to increase the CORe facility’s capacity to process food waste. The company has a contract with the Greater Lawrence Sanitary District (GLSD) to tip the slurry at the water resource recovery facility for codigestion. It is premixed with biosolids prior to being put into the digester.

One composting facility, Martin’s Farm Compost in Greenfield, received a RBDG grant for $146,000 that it will use to purchase a screener to remove small pieces of plastic, metal, glass and other inorganics from compost. Martin’s Farm anticipates composting as much as 9,000 tons of food material annually.

Hartford, Connecticut: Connecticut RFP Solicits AD And Other Clean Energy

The Connecticut Department of Energy and Environmental Protection (DEEP) has issued a request for proposals to procure up to 899,250 MWh/year of renewable energy and associated Renewable Energy Certificates (RECs) from offshore wind, fuel cell, and anaerobic digestion renewable energy resources, pursuant to long-term contracts of up to 20 years. Bidders must submit completed proposals to DEEP by April 2, 2018. Connecticut will announce winning bids in June 2018. The plants have to start generating power between July 1, 2019 and December 31, 2025. The proposed plants must have capacities of at least 2 MW. The maximum capacity for fuel cell and AD plants has been set at 20 MW and 5 MW, respectively, while there is no limit for the capacity of offshore wind and fuel cell with CHP facilities. All of them can include paired or co-located energy storage, DEEP said.

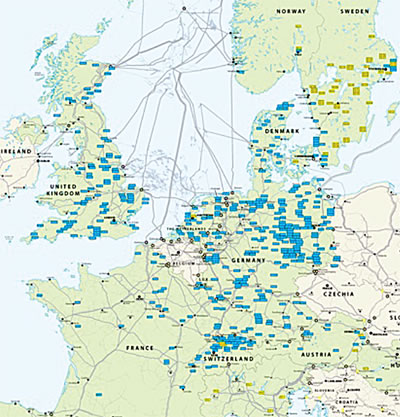

Brussels, Belgium: European Biomethane Map Illustrates Positive Trend

Rapidly growing interest worldwide in biomethane (renewable natural gas) produced by anaerobic digestion facilities as a fuel source for transportation led Gas Infrastructure Europe (GIE), in collaboration with the European Biogas Association (EBA), to publish the “European Biomethane Map 2018.” Europe had 17,662 biogas plants as of the end of 2016, with all European Union countries active in the field, along with Iceland, Norway, Serbia and Switzerland. Biomethane plants upgrade raw biogas to natural gas pipeline quality, which can then be injected into the local gas grid or used locally for heating or fueling purposes.Compared to the biogas electricity sector, biomethane is still in its infancy. In 2011 (the earliest data available from EBA), 187 biogas plants in Europe were upgrading their production to biomethane. The total number of biomethane plants grew quickly in subsequent years, reaching 497 installations in the first quarter of 2017. In 2016 alone, 41 additional biomethane plants were registered. The countries with the most biomethane plant construction in 2016 were Germany (+11 units), Sweden (+10 units) and France (+9 units).

Los Angeles, California: Utilities Release Solicitation For Dairy Biomethane Pilots

In December 2017, the California Public Utilities Commission (CPUC) issued a decision which establishes the necessary framework to direct natural gas utilities to implement not less than five dairy biomethane pilot projects to demonstrate interconnection to the common carrier pipeline system and allow for rate recovery of reasonable infrastructure costs pursuant to SB 1383, California’s short term climate pollutant mitigation law. Participating utilities are Southern California Gas Company (SoCalGas), Pacific Gas & Electric Company (PG&E), San Diego Gas & Electric and Southwest Gas Corporation.

These utilities recently issued a joint Request for Proposals for dairy biomethane pilot projects that would provide funding for development of biogas treatment facilities and collection lines, pipeline lateral extensions and compression facilities to deliver the upgraded biomethane to the utility system’s interconnection point, and the development of the interconnection point itself. The utility funds cannot be used to fund digesters, biogas upgrading facilities or end-use facilities (these project facets are eligible for funding under the California Dept. of Food and Agriculture Dairy Digester Research and Development Program). Proposals are due in June 2018.

Washington, D.C.: NREL Scientists Model Methane-Eating Bacteria

A research team that includes scientists from the U.S. Department of Energy’s National Renewable Energy Laboratory (NREL) explored how the bacteria Methylomicrobium alcaliphilum 20ZR uses methane, an abundant greenhouse gas, and converts it to a raw material for creation of new products. NREL researchers and coauthors Calvin Henard and Michael Guarnieri are members of a team looking to discover how M. alcaliphilum 20ZR, a methane-eating organism known as a methanotroph, operates. It was one of the first research initiatives of its kind. “Very little is known about methanotrophic metabolism in general,” explains Henard. “These are the first metabolic models generated for this particular organism, which is one of the most promising biocatalysts that can be used to make products from natural gas and biogas derived methane.”

Once the metabolism is defined, it can be manipulated and optimized for targeted production of fuel and chemical intermediates. The potential utility of the bacteria for biocatalysis, improved carbon utilization and simultaneous greenhouse gas mitigation spurred the research. M. alcaliphilum 20ZR can use methane as its only carbon and energy source. The reduction of methane could have environmental and health benefits. Methane-eating microbes such as M. alcaliphilum 20ZR are adept at manufacturing precursors of renewable fuels and chemicals. One of the processes looked at by the team resulted in production of precursors to nylon — a valuable consumer product whose production is traditionally very environmentally unfriendly. Ideally, they wanted to know if the organism could be engineered to be more effective and efficient.