Top: Certified compostable packaging was composted in laboratory vessels to identify process conditions that optimize biodegradation. Photos by Engineered Compost Systems

Tim O’Neill, Liv Johansson and William Meredith

A study was conducted at the Engineered Compost Systems’ (ECS) lab in 2023 to test the compostability of one of the most common bioplastics, polylactic acid (PLA), under controlled conditions. Bioplastics marketed as “compostable” are increasingly part of the feedstock mix at commercial composting facilities. Accepting certified compostable bioplastics can benefit a compost manufacturer when they facilitate increases in tip fee revenue, moisture and nutrients attributable to food waste. Bioplastics that degrade outside of the standard time frames for composting can result in visual contamination of the final compost. In this study, the primary goal was to begin to characterize how specific measurable compost process conditions impact bioplastic degradation rates so that facility designers and operators might use this data to improve the performance of these materials.

Chemistry Of Thermoresistant Bioplastics

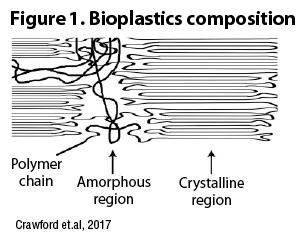

For years, compostable bioplastics were poorly resistant to heat when compared to conventional plastics. Developments in bioplastic chemistry improved heat resistance by increasing the crystallinity of bioplastics. Crystallinity refers to the structurally ordered regions of a material; the degree of crystallinity suggests how orderly and tightly knit the polymer chains of a material are, and, fundamentally, how stable that material is in solid form. Bioplastics with large amorphous regions have polymer chains “in a highly disordered and tangled state” (Crawford et.al, 2017), creating brittleness under physical stress or heat (Figure 1).

For years, compostable bioplastics were poorly resistant to heat when compared to conventional plastics. Developments in bioplastic chemistry improved heat resistance by increasing the crystallinity of bioplastics. Crystallinity refers to the structurally ordered regions of a material; the degree of crystallinity suggests how orderly and tightly knit the polymer chains of a material are, and, fundamentally, how stable that material is in solid form. Bioplastics with large amorphous regions have polymer chains “in a highly disordered and tangled state” (Crawford et.al, 2017), creating brittleness under physical stress or heat (Figure 1).

Bioplastics with higher degrees of crystallinity and molecular weight are more resistant to heat and stress, making them suitable substitutes for many foodservice applications (e.g. coffee cups, coffee cup lids). However, there is an inverse relationship between the degree of crystallinity and heat conditions, i.e., the better they are for holding your coffee, the less likely that they will compost successfully.

Polymers are the structural backbone of every plastic. All plastics are repeating chains of different polymers. Different types of polymers and how they are linked together will impact how easy it is for microbes to take them apart. The process of microbial decomposition or separation of the polymers is known as mineralization. Mineralization occurs when enzymes interact with material surfaces and break the available polymers into oligomers and monomers, which are then consumed (assimilated) by the microbes for their survival. The “oligomers and monomers assimilated within the cells are converted to carbon dioxide (CO2) and water (H2O) (aerobic), and CO2, methane (CH4), and H2O (anaerobic)” (Zambrano et.al 2020). The cycle continues until the material has been fully biodegraded.

The challenge for composters is that “the accessibility of the polymer structure to enzymes and water depends primarily on crystallinity ” (Zambrano et.al 2020), and the higher the degree of crystallinity the lower the rate of mineralization and bio-oxidation of the bioplastic by compost microbes. In addition, different chemical bonds within polymers can impact how easily microbes can decompose the material.

Compostable plastic producers continue to develop bioplastics that have higher degrees of crystallinity. In many ways, this makes them better products and more like their fossil fuel counterparts. Two major developments have been Crystallized PLA (cPLA) and Talc-injected PLA (tPLA) — both chemically altered to improve their heat and stress resistance. The cPLA and tPLA are some of the most commonly used bioplastics and are suggested to be easily compostable in the scientific literature. The benefits of cPLA and tPLA are that they can withstand temperatures of up to 180°F and can be made into reusable and dishwasher-safe products.

Manufacturers report that tPLA products require three to six months of commercial composting time, and cPLA requires two to four months of commercial composting time, with additional studies suggesting that composting times in excess of six months are still inadequate for complete biodegradation of PLA-type bioplastics. These broad ranges in required processing time are indicative of the general lack of data to correlate process conditions, such as temperature, oxygen level, pH, and moisture, with rates of biodegradation. Better understanding the correlation between processing conditions and biodegradation motivated ECS’ testing efforts.

Laboratory Apparatus

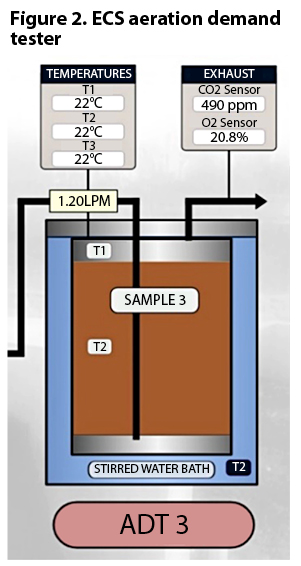

ECS’s Compost Process Lab is equipped with three instrumented Aeration Demand Testers (ADTs) that provide controlled composting process conditions and measure the real-time levels of CO2 and O2 (the primary indicators of composting activity). ADTs aerate a 15-liter reactor volume while controlling the surrounding water-bath temperature to within +1°C and airflow to within 2% of full-scale. By adjusting the rate of air flow, the range of oxygen levels can be indirectly controlled. These data provide insight on how process conditions and whole mix characteristics impact the rate of bioplastic biodegradation.

ECS’s Compost Process Lab is equipped with three instrumented Aeration Demand Testers (ADTs) that provide controlled composting process conditions and measure the real-time levels of CO2 and O2 (the primary indicators of composting activity). ADTs aerate a 15-liter reactor volume while controlling the surrounding water-bath temperature to within +1°C and airflow to within 2% of full-scale. By adjusting the rate of air flow, the range of oxygen levels can be indirectly controlled. These data provide insight on how process conditions and whole mix characteristics impact the rate of bioplastic biodegradation.

Each ADT is a sealed stainless-steel vessel nested within another steel vessel that serves as a stirred, temperature-controlled water bath. Sensors monitor the temperature in the headspace (T1), compost sample (T2), and in the water bath (T3), as illustrated in Figure 2. All sensor data is logged every ten minutes.

Phase 1 Tests

The Phase 1 tests, designed to observe the impacts of heat, moisture and biology, had two goals: 1) Isolate the effects of temperature and moisture on plastic decomposition outside of a compost pile; and 2) Begin to characterize the effects of temperature within a composting environment. Seven tests were conducted on the same selection of readily available, ASTM D6400 and D6868 Certified PLA products (Figure 3).

Each of these seven process condition tests were continuously maintained for 21 days; all were “static” (non-agitated). The composting tests used a substrate mix of 80% ground yard waste and 20% ground produce waste on a weight basis. After 21 days, the test items were visually observed and recorded. Figures 4 and 5 report the process conditions and outcomes.

Phase I Findings: From the results of these tests, it appears that elevated temperatures and moisture alone have a limited impact on the degradation of the bioplastics tested. On the other hand, exposure to the active composting environment (compostable substrate mix) increased the degradation rates of the film bag, the low temperature PLA cup, and the fiber coffee cup. Overall, the degradation rates of these items appeared to increase with increased temperature. Neither the white food serviceware nor the coffee cup lid were noticeably degraded by the active composting environment at any of the three temperatures tested. It should be noted that the moisture levels in the ADTs were high (close to the water holding capacity of the substrate) throughout the 21-day test which would, in theory, optimize the potential for hydrolysis of the bioplastics. In practice, moisture levels tend to be lower in windrow or aerated static pile composting methods.

Phase 2 Tests

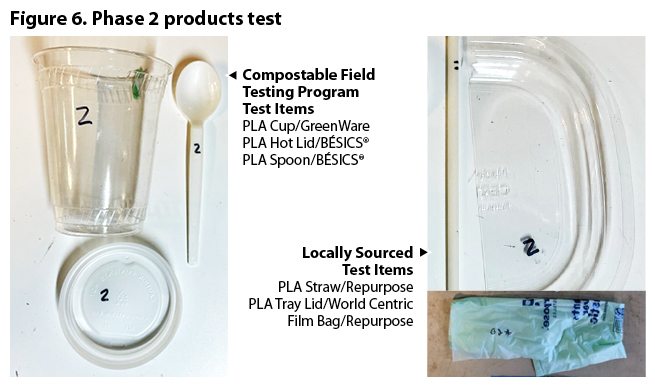

Building off the work of Phase 1, ECS developed the Phase 2 test plan to measure the effects of a range of higher temperatures on bioplastic degradation. The goal was to find temperatures that would accelerate bioplastic degradation enough that the process could then be completed at temperatures below 60°C that are desirable to optimize the rate of stabilization and minimize air emissions. Phase 2 included a wider array of products, including items used in the Compost Research Education Foundation’s Compostable Field Testing Program (Figure 6). In Phase 2, the bioplastics were observed more frequently during the composting process to develop a better understanding of the relationship between degradation rates and process conditions over time.

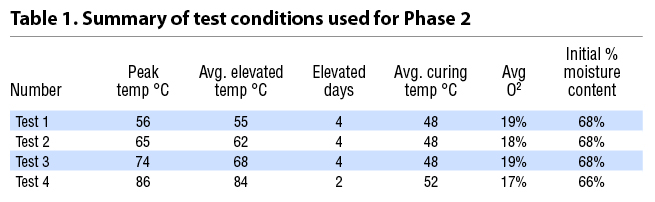

Test Design: Phase 2 included four tests. All were started with an early warming period below 45°C to allow the mesophilic bacteria to neutralize the acidic food waste prior to shifting into thermophilic temperatures, avoiding low pH inhibition. Each test had a limited period of peak temperature. Tests 1, 2 and 3 ran for 31 days. The ADTs were opened on day 11, 18, and 31; the bioplastics were removed, photographed, and measured. Eight days into the trial period, it was observed that the standard heating methods of the ADTs could not achieve the planned high temperature of 85oC. On day 11, when the bioplastics were first removed from all ADTs for evaluation, the labeled bioplastic test items of ADT 3 were added to ADT 2 as the curing temperature was to be the same.

The ATD 3 vessel was then reloaded with the same compost substrate mix and bioplastics test items. This became Test 4, which started with a 2-day mesophilic period, then was removed from the stirred water bath, connected to a separate aeration source to maintain surplus oxygen, and placed in an oven where it achieved the target temperature of 85oC. The elevated temperatures achieved, retention times, and curing temperatures are listed in Table 1.

The compost substrate blend was composed of 40% ground green waste, 41% woodchips, and 19% food waste on a weight basis (Figure 7). Total bulk density of the mix was 840lbs/cubic yard with starting moisture content of 68%.

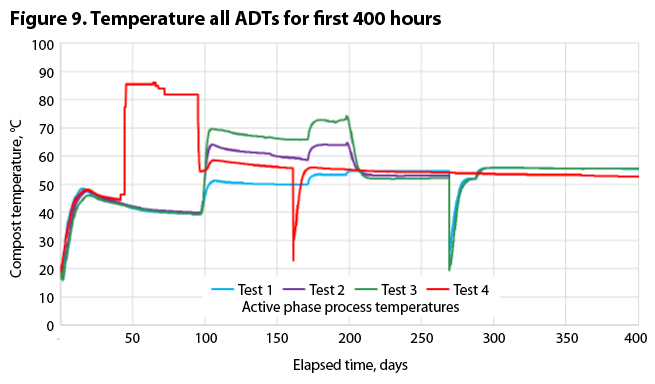

Each of the three ADTs was filled with alternating layers of the substrate mix and bioplastic test items to ensure that all surfaces of the bioplastics were fully in contact with the compost substrate, and not each other (Figure 8). Substrate mix was also placed inside the mesh bags with the test items for this same purpose. The ADTs were then sealed and subjected to the temperatures listed in Table 1 and shown in Figure 9.

The recorded oxygen consumption and CO2 generation demonstrated that rate of biodegradation of the substrate mix was not inhibited by pH, moisture, C:N, nor the presence of the bioplastics themselves. In other words, the bioplastics did not inhibit the composting process. In the units where the temperature exceeded 62oC, microbial respiration declined. This result is in line with established research on thermal inhibition generally observed in composting.

The recorded oxygen consumption and CO2 generation demonstrated that rate of biodegradation of the substrate mix was not inhibited by pH, moisture, C:N, nor the presence of the bioplastics themselves. In other words, the bioplastics did not inhibit the composting process. In the units where the temperature exceeded 62oC, microbial respiration declined. This result is in line with established research on thermal inhibition generally observed in composting.

Phase 2 Findings

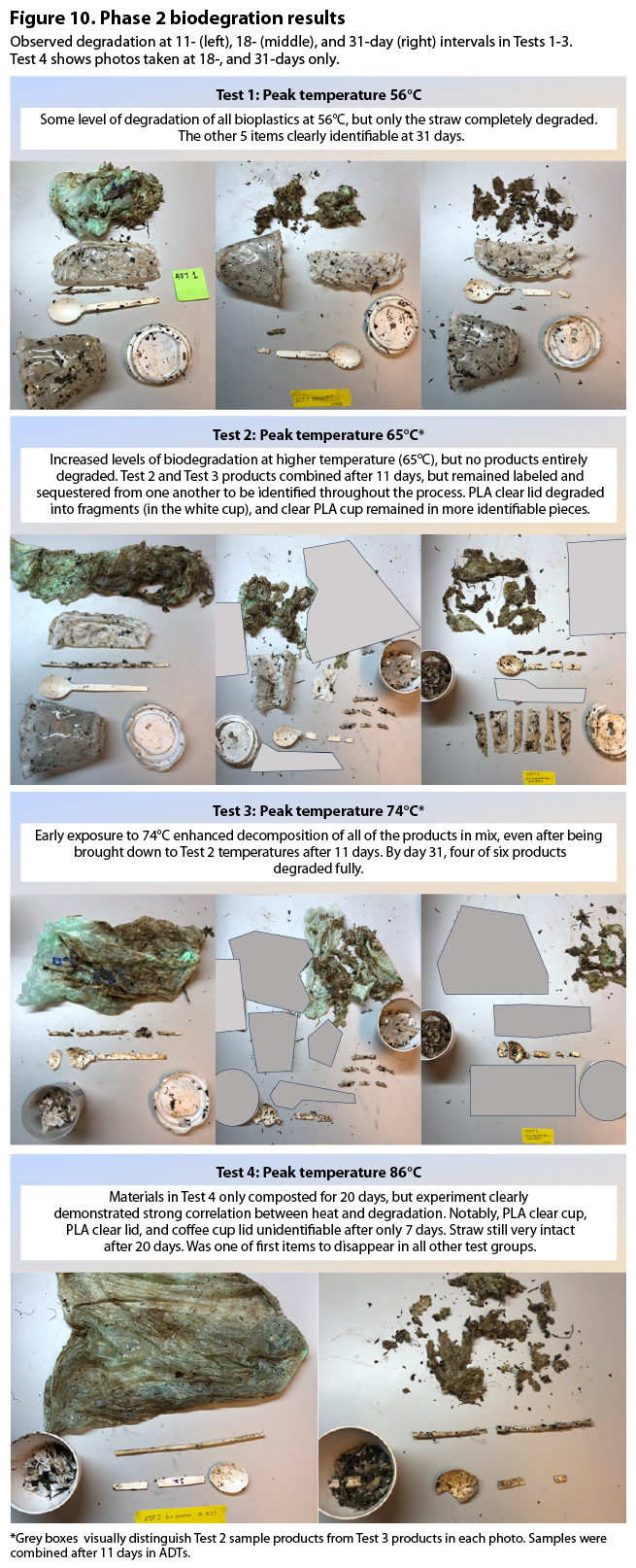

Biodegradation: The results of the tests suggest that time and temperature both play a critical role in the rate of bioplastics biodegradation. Figure 10 shows the observed degradation at 11- (left), 18- (middle), and 31-day (right) intervals in Tests1-3. Test 4 shows photos taken at 18-, and 31-days only.

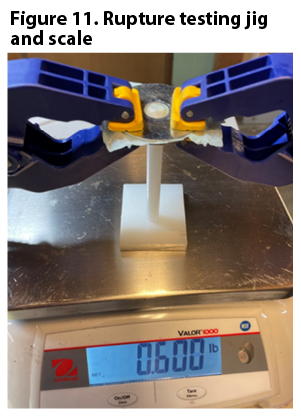

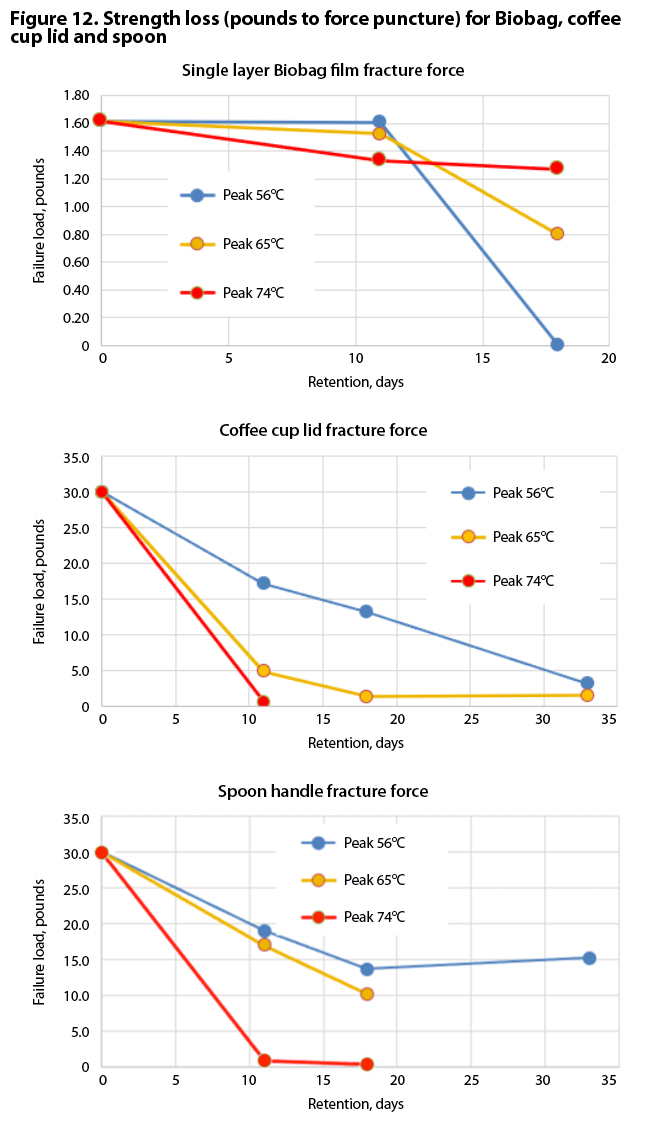

Strength Loss: Optimized static active phase composting is typically followed by turned windrow curing. Thus, the rate of strength loss in the Phase 2 tested bioplastics was of interest since weakened bioplastics could mechanically disintegrate in the turning process. To measure strength loss, items were tested at day 11 and 18 in Tests 1, 2, and 3 of the Phase 2 trial. The coffee cup lid, spoon handle, and Biobag® were rupture tested using a simple jig and scale to puncture them (Figure 11).

All three product types appeared to have lost strength over the test period, with higher temperature accelerating the loss of strength in the coffee cup lid and the spoon handle. Conversely, it appears that the Biobag’s strength loss at the 18-day mark was inversely proportional to temperature, losing more of its strength in the 55oC ADT (Figure 12). Only fragments that could be identified and mounted in the jig were strength tested at each point.

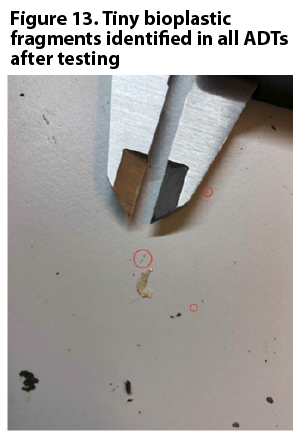

Fragmentation: At the end of the experiment, the presence of minuscule plastic fragments throughout the compost was observed (Figure 13). These fragments’ product origins could not be determined, though they were mostly observed to be white, and they appeared in all the ADTs at the end of testing. This would suggest that even if bioplastics appear to the untrained eye to mechanically disintegrate, an unknown amount of additional time would be required for them to become fully degraded.

Fragmentation: At the end of the experiment, the presence of minuscule plastic fragments throughout the compost was observed (Figure 13). These fragments’ product origins could not be determined, though they were mostly observed to be white, and they appeared in all the ADTs at the end of testing. This would suggest that even if bioplastics appear to the untrained eye to mechanically disintegrate, an unknown amount of additional time would be required for them to become fully degraded.

Conclusions

These scoping tests provide insights into the behavior of bioplastic degradation rates as a function of process conditions. The ECS results indicate that there are correlations between temperature and rates of bioplastic degradation in an active composting environment. Higher temperatures resulted in more rapid and complete degradation. It was also clear that elevated temperatures and moisture alone were insufficient to degrade bioplastics, indicating that bio-oxidation plays a significant role.

The importance of higher pile temperatures to accelerate degradation could be a concern for composting processes that are static, such as ASPs and most in-vessel systems, since in practice large piles are far from isothermal; a wide range of temperatures can be measured throughout the pile. Additionally, the most elevated temperature (86°C, peak), which provided the fastest rates of degradation for most of the test items, would be difficult to achieve with most commercial systems and feedstocks. Sustained temperatures above 65°C are undesirable as they result in slower rates of stabilization and increased air emissions.

Variability in degradation rates between the different test items indicates that the biodegradability of all items “Certified Compostable” will not be optimized by a single series of process conditions. We understand that the chemical structure (crystallinity) of the white test items is by design, so that they can withstand higher temperatures and/or provide more rigidity to foodservice ware. This crystalline structure makes these products less amenable to biodegradation even at the more elevated temperatures produced in Phase 2. On the other hand, the clear PLA items tested appeared to readily disintegrate into small particles at more modest temperatures. The film bag’s degradation rate appeared to benefit from being in full contact with composting substrate at moderate composting temperatures as well as degrading even more quickly during the curing phase following exposure to the maximum temperatures of 86°C. It should be noted that this trial focused only on PLA-based bioplastics. Other materials are likely to behave differently.

Tim O’Neill, president and founder of ECS, has worked in the compost industry since 1993 and has been responsible for the development and manufacture of compost process control systems. His expertise includes compost aeration and control, regulatory compliance, and process and monitoring technology. He serves as a Trustee for the Compost Research and Education Foundation. Liv Johansson supports science, education, public policy, and permitting work at ECS, and formerly served as a compost facility operator for the Woodland Park Zoo’s manure composting operation. She is treasurer of the Washington Organics Recycling Council and leads the Council’s annual Compost Facility Operator Training course. William Meredith is ECS’s laboratory technician and is instrumental in facilitating all ECS laboratory work.