Nine brands of cutlery marketed as compostable were put through a degradation test at a Vermont composting facility that utilizes the aerated static pile method.

Nate Clark

BioCycle December 2014

In December 2009, management at Green Mountain Compost (GMC), a commercial composting facility (formerly known as Intervale Compost Products) located in Williston, Vermont, enacted a compostable cutlery ban, restricting any generators from sending these products to the facility for processing. “We were kind of forced into creating policy around acceptance of compostable plastics as they entered the marketplace and started showing up in the waste stream,” explains Dan Goossen, General Manager of GMC. “Beginning in 2008, lots of knives, forks and spoons were coming out with our screened overs. This required many hours of hand picking to remove them from the overs stream and ultimately led to our decision to say no to compostable cutlery.” Compostable liners, in addition to bowls, plates, cups, etc., were still accepted.

GMC’s compostable cutlery ban received a fair amount of media attention. Some distributors of compostable plastics, advertising their products as a “green” solution to waste reduction, were upset by the ban as it brought compostability claims into question. In addition, large generators that utilized GMC for processing were forced to stop using compostable cutlery. “The universities and other larger generators that we service prefer to have all compostable inputs in their cafeterias because it really simplifies things (i.e. source separating),” notes Goossen. “With the ban in place, this was not possible.”

Despite GMC’s ban, compostable cutlery brands continued to pop up on the market, and generators continued to purchase the products as an effective tool for facilitating successful food scraps diversion programs. In Vermont, the first state in the U.S. to pass a universal recycling law that bans organics from the landfill by 2020, GMC is consistently under the microscope as a testing ground for organics recycling as a whole. It is for reasons like this that in September 2013, Goossen and Jennifer Baer, GMC Sales and Production Coordinator, decided it was time to reconsider the cutlery ban. But before any final decision was made, Goossen and Baer put nine brands of compostable cutlery to a “degradation test” in GMC’s composting system to gather evidence to support their decision. (A degradation test is essentially a disintegration test, which is one of four components of the ASTM compostability assessment.

Each compostable cutlery sample was weighed and then placed in a heavy-duty nylon mesh bag (above) containing several scoops of GMC’s bulk compost recipe.

Testing Protocol

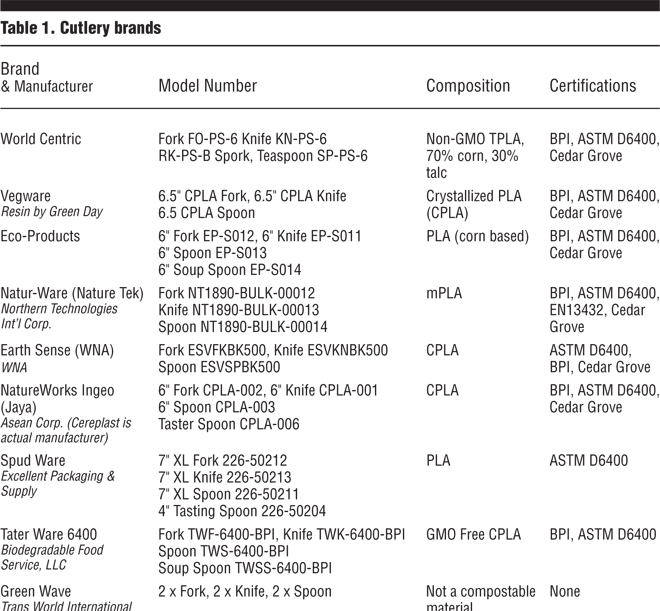

The compostable cutlery brands (Table 1) utilized in GMC’s experiment were made from polylactide (PLA); eight of the nine brands met ASTM D6400 standards and were BPI (Biodegradable Products Institute) certified. To determine which compostable cutlery brands to test, Goossen and Baer contacted local distributors and asked what brands they normally sell, knowing those are the ones that will most likely go through GMC’s system. The facility uses an aerated static pile (ASP) composting system. Each batch of compost goes through two aeration phases then is screened prior to a curing phase. The compostable cutlery trial utilized this process, with the exception of screening, for a total of 173 days of composting.

Each compostable cutlery brand (referred to as “sample”) was weighed and then placed in a heavy-duty nylon mesh bag containing several scoops of GMC’s bulk compost recipe. It should be noted that GMC has two distinct compost manufacturing streams: a certified-organic stream that does not allow any compostable products and a noncertified stream that accepts compostable products. Sample bags were then buried 3 to 4 feet within a compost pile. In Phase 1, samples underwent 17 days of static aeration (average temperature of roughly 140°-150°F) before being removed and remoistened, a standard procedure in GMC’s composting process. Sample bags were directly remoistened to ensure adequate moisture for continued composting. For Phase 2, samples were reinserted into a new pile of partially composted materials for an additional 27 days of aeration (temperature range of roughly 110°-140°F).

Following Phases 1 and 2 (a total of 44 days of aeration), each sample bag was emptied and its contents picked through. Visible pieces of cutlery were removed, photographed, and weighed. Sample bags were then refilled with compost from the pile from which they came, and the leftover pieces of cutlery were mixed back into their respective sample bags. The bags were then buried 3 to 4 feet in a curing pile consisting of the same compost material that surrounded the sample bags during aeration.

Test Results

Samples underwent 129 days of curing at mesophilic temperatures — between 90°F to 115°F before being removed at 173 days. Again, sample bags were emptied and contents picked through. Visible pieces of cutlery were removed, photographed and weighed. However, some samples were not weighed after curing because they were almost fully degraded down to tiny pieces that would have been nearly impossible to pick out and/or distinguish from other material contained in bags. The degree of degradation was determined by visual examination of photographs and consideration of decrease in total sample mass.

Results from the compostable cutlery trial are provided in Figure 1. All eight of the BPI-certified sample brands were found to “fully” or “mostly” degrade after the 173-day composting process representative of GMC’s system. The Green Wave cutlery sample utilized in the experiment turned out to be an older formulation that is not compostable and was sent to GMC erroneously (this sample did not carry BPI certification). As noted, the samples did not undergo a screening process. GMC screens compost to three-eighth-inch prior to the curing period, and it is likely any intact pieces would have been screened out for further composting.

“The GMC test was well-run and well-documented,” notes Steven Mojo, BPI’s Executive Director. “It focused primarily on the ability of the samples to disintegrate under GMC’s unique composting process. GMC’s test is complementary to that of the BPI and the ASTM standards. Under ASTM D6400, for example, manufacturers test for satisfactory disintegration and complete biodegradation under thermophilic temperatures found in most industrial composting sites. These are standardized tests that minimize the variations found at actual composting facilities.”

Lifting The Ban

The compostable cutlery experiment gave Goossen and Baer confidence that cutlery products labeled as compostable are by and large compostable. Therefore in April 2014, GMC’s compostable cutlery ban was lifted. “Our biggest concern with compostable cutlery products is that they: a) Do not contain any traditional plastics or foreign materials that we do not want in our finished compost; and b) Break down to the point where they are no longer visible,” notes Goossen. “If these two conditions are met, we are satisfied. Based on what we witnessed in our trial, we now have the confidence that BPI certified products are actually going to degrade to the point where they’re no longer a nuisance.”

Given that compostable certifications have proven effective at determining which products do and do not degrade, Goossen and Baer believe it is now a matter of accurately and clearly labeling products. “What is really important now is that the compostable plastics industry, which is manufacturing these products, gets the message from composters and others that they really need to do a better job of labeling and educating customers,” adds Baer. “The level of consumer confusion surrounding compostable products is really high — people in the community want to do the right thing but have no idea what the difference is between compostable and biodegradable [no certifications for biodegradation currently exist], and the labeling on these products is terrible.”

Goossen agrees. “As composters, everyone expects us to take everything,” he explains. “We [composters] are on the receiving end of a product [compostable plastics] that doesn’t benefit compost at all. We accept this material, so in return, I expect compostable plastics manufacturers a to do a better job labeling and differentiating their products as certified compostable.”

Nate Clark is a Contributing Editor to BioCycle.