Composting agro-industrial residuals — from livestock manure to sugarcane sludges — is on the rise, with compost utilized for agricultural production.

M.J. L. Beltrame, K. Goldschmidt Beltrame and F. Carvalho Oliveira

BioCycle September/October 2019

The Tera Ambiental Ltda. facility (Jundiai, State of São Paulo, Brazil), which uses both turned windrows and aerated static piles, features a composting capacity of 90,000 tons/years.ABISOLO (Brazilian Association of Plant Nutrition Technology Industries) was founded in 2003 to represent and protect the interests of companies producing agricultural inputs, including those using composting in their industrial processes. Its more than 100 members are in 9 of the 20 states in Brazil that have plant nutrition technology industries; the largest representation (29%) is in the State of São Paulo. In 2018, the Plant Nutrition Technology sector invoiced US$2 billion, producing 7.4 million tons of inputs. This sector invests, on average, 3.6 percent of revenue in research and development, generating 19,600 direct jobs.

The agro-industrial composting segment in Brazil has great growth potential. Generators include the intensive livestock production sector, and the sugar cane, pulp and paper, slaughterhouse, and citrus agro-industries, among others. In urban centers, organic waste streams include solids from sanitary sewage treatment and industrial wastewater plants, source separated green waste and pre and postconsumer food waste, and the organic fraction of municipal solid waste.

According to the Institute of Applied Economic Research (IPEA, 2012), agricultural production, such as soybean, corn, sugar cane, beans, rice, whole wheat, coffee and oranges, generated approximately 300 million tons of waste. By comparison, the livestock sector and associated agro-businesses, such as confined poultry rearing, dairy and beef cattle and pigs, were responsible for about 1.7 billion tons. (In 2017, Brazil’s agribusiness sector produced about 215 million bovine, 40 million pigs, and 1.5 billion chickens.) The forestry sector generated 40 million tons. While a significant portion of the waste generated by beef cattle is dispersed in the pastures, the increasing value of arable land is causing a migration of animal production to confined systems, concentrating organic waste generation.

Composting Regulations

ABISOLO actively participates in developing clear and objective legislation for the composting sector. It intensively engages in both environmental and agronomical discussion forums, and meets with CONAMA (National Environment Council), the Ministry of Agriculture, Livestock and Supply (MAPA), and other agencies in the states.

Brazil has an environmental regulatory frameworks governing the composting sector, however — especially for urban and industrial organic waste streams — landfills are still an attractive alternative because of the costs involved with developing a composting operation. Some Brazilian states have prescribed procedures for implementation of composting facilities that have the specific purpose of producing organic fertilizers. These include the states of São Paulo, Paraná, and Minas Gerais. In general, requirements are to waterproof the composting yards to avoid contamination of the water table and collect rainfall that comes in contact with the windrows for later treatment on-site or proper disposal.

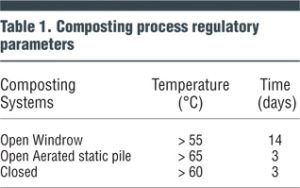

In 2017, CONAMA published a resolution (#481) to standardize, nationwide, minimum environmental protection procedures for the composting process. The biggest improvement brought by this resolution was to establish specifications of time and temperature parameters in the process, aiming at product hygiene, which was never previously described in any legislation. Table 1 outlines the parameters.

Brazil also has comprehensive legislation regarding products resulting from the composting process. This product legislation is ruled by Laws, Decrees and Normative Instructions, all under the direction of MAPA. It describes in detail all administrative and operational procedures of all stages of the process, from inputs that can be used, such as quality and tolerance criteria, to contaminants in final products, labeling, packaging, registration, laboratory analysis and marketing.

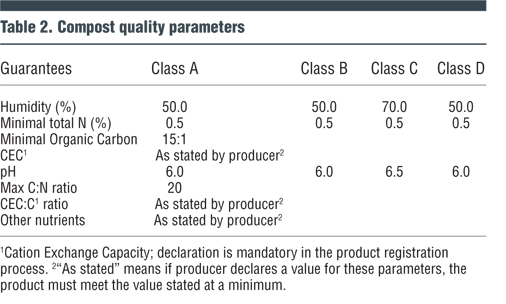

Table 2 highlights some of the parameters. (The values reflect minimum guarantees found in the Normative Instruction #25/2009.)

The rules created four classes of compost products that are safe for use in conventional agriculture. There are separate rules for organic agriculture that follow international standards.

Class A: Products that use raw material of plant origin, animal origin or from agro-business processing, in which toxic heavy metals, potentially toxic synthetic organic elements or compounds are not used.

Class B: Products that use raw material from processing of industrial activity or from agro-industry, in which toxic heavy metals, potentially toxic synthetic organic elements or compounds are used in the process.

Class C: Products that use any quantity of raw material from domestic waste.

Class D: Products that use any quantity of raw material from sanitary waste treatment.

MAPA is expected to issue a new Normative Instruction soon that will consolidate the four classes into two classes — one with sewage sludge and/or MSW waste without “selective” (i.e., source separated) collection that cannot be used on crops where the edible part has contact with the compost, and another with neither sewage sludge or MSW.

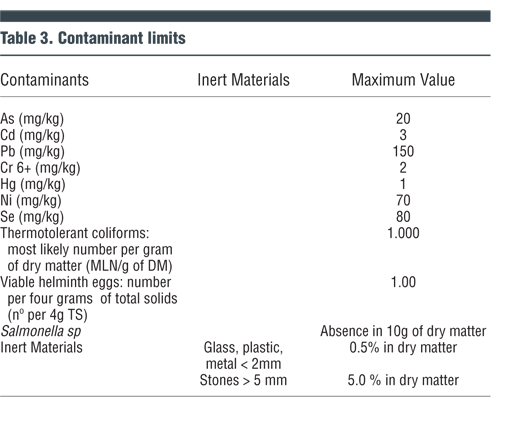

Another important Normative Instruction limits contaminant levels in products, regardless of class. Table 3 includes the contaminant limits.

Facility Characteristics

Most composting facilities in Brazil use the turned windrow composting method, although some utilize the aerated static pile (ASP) process, depending on the raw materials being composted. For example, ASP is used to compost sewage sludge and food waste to prevent odors. For other types of waste, mainly from sugarcane, turned windrows are used.

The majority of composting companies in Brazil are dedicated to treating waste generated by agricultural activities and their associated agro-businesses, e.g., poultry litter, slaughterhouse waste, and sludge from wastewater treatment in agro-industrial processes. Large agro-industry sectors sometimes install composting plants dedicated to their own waste. These primarily include the sugarcane and paper and pulp agro-industries, all which process large quantities. Plants dedicated to the industrial waste segment generally do so within a cocomposting context, processing agricultural, MSW, and agro-industrial waste. A small but expanding sector is composting plants dedicated to the treatment of sewage sludge and organic urban solid waste, as there is a need for a more rational destination for sewage sludge than the landfill. About 90 percent of these cocomposting facilities process a mix of organic streams; the other 10 percent cocompost sewage sludge and urban organics.

Valoriza Fertilizantes Ltda., in Uberlândia, State of Minas Gerais (left) and Organosolvi Soluções Orgânicas S.A., in Coroados, State of São Paulo (right).

Composting Operations

Tera Ambiental Ltda., in the city of Jundiai, State of São Paulo, has capacity to compost 90,000 tons/year of organics, primarily sludges from biological treatment of sanitary sewage. However, it jointly processes sludges from wastewater treatment from the agro-industry, and food waste. Tera Ambiental utilizes both a turned windrow system and aerated static pile.

Valoriza Fertilizantes Ltda., in the city of Uberlândia, State of Minas Gerais, has capacity to process 120,000 tons/year of organics, mostly from agricultural origin (mainly poultry rearing). It also composts sludges from wastewater treatment of agri-food industry and food waste. It utilizes aerated static piles.

Organosolvi Soluções Orgânicas S.A., in the city of Coroados, State of São Paulo, has capacity to process 170,000 tons/year of organics, mostly from agricultural origin (mainly poultry rearing. It also composts agri-industrial sludges from wastewater treatment of processing meat and other foods. Aerated static pile composting is used.

Composts produced by these facilities are utilized on all types of agricultural crops. As noted, compost containing municipal sewage sludge cannot be used on crops where compost could come in contact with the edible part of the plants.

Moacir J. L. Beltrame, MSc., Civil Engineer, and Katia Goldschmidt Beltrame, MSc., Agronomist, are Technical Advisors to ABISOLO Organic Fertilizers. Fernando Carvalho Oliveira, PhD, Agronomist, is Technical Manager of TERA Ambiental Ltda., and Director of ABISOLO Organic Fertilizers.