BioCycle May 2012, Vol. 53, No. 5, p. 10

Cambridge, Massachusetts: Harvard Steps Up Organics Recycling

Harvard University was diverting just 5 percent of its waste stream from the landfill in 1989. By 2011, that figure had climbed to 50 percent, says Rob Gogan, the university’s Recycling and Waste Manager. Harvard began its organics recycling program with animal bedding and in 1997 was recycling food scraps as well. Gogan presented aspects of the school’s program during a US EPA webinar entitled “Food Recovery at Universities and Colleges.” He explained that reducing the amount of food wasted is a key starting point for programs, and that conducting waste audits is a good first step to identifying where waste is being created. “Measure what’s actually in your trash, and chart progress from year to year,” he said. For example, a random 2011 sampling of Harvard’s dorm trash revealed 41 percent paper, boxes, bottles, cans and other materials that could have been recycled, 38 percent organics and liquids, including 20 percent compostable food scraps, 4 percent clothing and office supplies and 18 percent films, foams and personal hygiene materials.

Back-of-the-house waste prevention measures have included ordering the correct quantity of foods students will actually eat, researching favorite foods and training staff to minimize waste — including education about proper organics recycling.

Pottstown, Pennsylvania: Arborist Expands Into Composting

As the name implies, Arborganic Acres is a hybrid of sorts. When the economy slowed, arborist Bob MacMullen was looking for an environmentally friendly way to diversify his business. He also had an abundance of wood chips from his M&M Tree Service. That’s when he, with help from business partner Thomas Shine, decided to branch out into composting, opening Arborganic Acres for business in June 2010 to process municipal, residential and commercial (landscaping service) yard trimmings. Four months later he received a permit from the Pennsylvania Department of Environmental Protection (PaDEP) to accept fruit, vegetable and grain waste. Clients include a nearby Walmart and Victory Brewing Company about 20 miles away.

The facility’s current GP 17 Permit from PaDEP, which expires in September, only allows it to compost 500 tons of food waste annually. The agency is working on new permitting rules that would increase that amount, but until a new permit is actually in place, MacMullen says his hands are tied. “Food waste recycling in Pennsylvania is kind of stalled right now.”

Composting at Arborganic Acres starts on 46-foot by 30-foot blacktop pads under open sided containment buildings, using 1.5 HP Dayton blowers to negatively aerate the material to help control odors and jumpstart the composting process. Materials remain there for two weeks before being moved to a second-stage 3-acre compost pad, where they are positively aerated with the same type of blowers. Total processing time averages 16 weeks. The Powerscreen 511 trommel helps produce a variety of products including screened compost and a bed and garden mix (screened topsoil and compost), each sold in bulk for $35 a yard and also in bags through area garden stores. An Olathe tub grinder is used to make double and triple ground organic mulch. Learn more about Arborganic Acres at BioCycle’s FindAComposter.com.

San Diego, California/Hardwick, Vermont: Coast-To-Coast Partners Pilot Vermicompost System

A partnership between VermiVision Inc. (San Diego) and Highfields Center for Composting (Hardwick) combines its proficiency with aerobic-thermophilic compost preparation. “In 2011, we sponsored installation of a 40-foot continuous-flow (CF) worm digester bed as a pilot project at Highfields,” says VermiVision President Ralph Crevoshay. “The system is the recently-introduced design by Jack Chambers of Sonoma Valley Worm Farm. Jack supervised the installation in a ‘worm parlor’ created by Highfields staff in an unused lumber shed at its composting site, which is 6 miles away in Wolcott.”A bank of aerated static piles (ASPs) was built adjacent to the worm parlor. “A network of subsurface pipes captures heat from the negative-flow airstream of the ASPs and delivers it to the parlor’s floor to maintain worm-friendly ambient temperatures during long and frosty Vermont winters,” adds Crevoshay. The process begins with a three-week phase of aerobic composting of a mixture of manure-based material that typically includes a woody carbon source and up to 25 percent food waste. The resulting feedstock fills the CF beds on a continuous basis, guaranteeing perpetual harvests. The collaboration between VermiVision and Highfields is expected to generate system modifications adaptable to a wide variety of geographical conditions and organic waste sources. After a year to 18 months of pilot operations under the supervision of the University of Vermont’s College of Agricultural and Life Sciences, the partners plan to scale up the facility to commercial dimensions to serve regional needs. The company also plans to install a similar system at Cal Poly in San Luis Obispo (California), cosponsored by the College of Agriculture, Food and Environmental Sciences’ Center for Sustainability.

Pawlet, Vermont: Composting Entrepreneur’s “Unreasonable Invention”

Agrilab Technologies, LLP, a Vermont based business that has developed a method of capturing heat from composting and converting it into thermal energy, has been selected to participate in a program designed to give environmental entrepreneurs who are thinking outside the box a boost to get their projects off the ground. Organized by the Boulder, Colorado-based Unreasonable Institute, the program puts project developers together with alternative business and technology mentors as well as likely investors. Two of Agrilab’s heat-transfer systems are operational in New England, with a third in construction. In 2010, a Vermont farm where one of the units is installed won the Governor’s Award for Environmental Excellence & Pollution Prevention.

Agrilab was one of 46 projects selected by the Institute, which has the stated goal “to unlock entrepreneurial potential to overcome the world’s biggest challenges.” The first 25 of those selected companies to raise $10,000 for their projects earned themselves a spot at the six-week boot camp, taking place this summer. “We have low-tech heat capture systems ideal for developing countries as well as the U.S., Canada and Europe’s larger farms, Agrilab partner Josh Nelson explained on a website video produced to help raise the cash, “and we have documented that we capture an average of 1000 BTU/ton of composting material per hour.” The system pulls heat generated from the composting process into a preheater, where the ends of rods running the length of cylindrical heat sinks filled with water (known as isobars) transfer the heat to the water. The heated water (up to 120°F) can then be used for a variety of applications, such as warming buildings, greenhouses or other structures. The systems are scalable and not necessarily limited to agricultural applications, says Nelson.

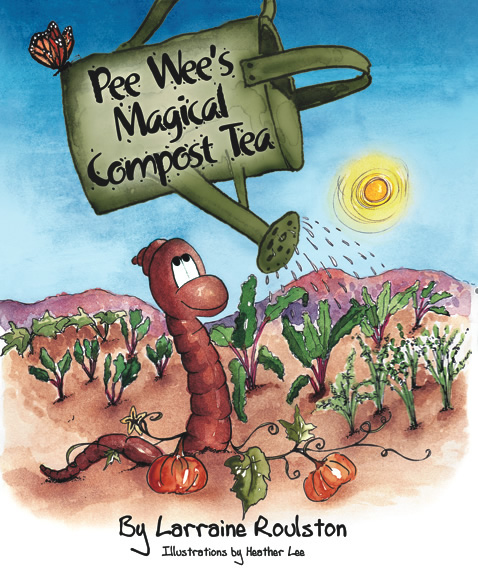

Havelock, Ontario: Kids Composting Books

Larraine Roulston began writing her “Pee Wee” composting books for children a number of years ago. The first of the series, Pee Wee and the Magical Compost Heap, introduces children to backyard composting through the adventures of Pee Wee, “the endearing little red wiggler worm, and all the insects in the compost heap,” says the description on Roulston’s website. The story in Pee Wee’s Magical Compost Tea, Roulston’s latest book, takes students on a Waste Reduction Week event to learn the benefits of compost tea. Pee Wee and the compost critters plan a compost tea party inside a rotting Jack O’Lantern. Roulston also created a 24-page coloring and activity book. Visit www.castlecompost.com.

Poughkeepsie, New York: One Million Pound Milestone

Marist College began composting dining hall food waste in September 2007 and recently passed a milestone of one million pounds diverted from the landfill. That achievement hasn’t gone unnoticed, with the school being named the per capita Organic Reduction Champion of the US EPA’s WasteWise program Game Day Challenge two years in a row. The program started when students from Marist visited nearby Vassar College where Greenway Environmental Services had set up a food waste composting program several years earlier. “In the interest of getting good clean food waste into our facility, we began designing food collection systems,” says Greenway partner Josephine Papagni, whose company also services Marist College. “We’re talking about old buildings that were never designed to manage solid waste the way we need to today.” This includes loading docks where every square foot of space is coveted real estate, she adds. “We come in and say ‘We have a way for you to manage wastes, and try to make them see that our system actually reduces the footprint. If you take the food waste out, the compactor size can shrink.”

Mt. Vernon, Maine: Soil Assessments Forget The Biology

Thirty years ago this spring, Bill Liebhardt and his colleagues published results of a controversial survey of 69 U.S. soil laboratories. All the labs had received five farm soil samples with accompanying crop histories and a request for recommendations to grow 125 bushels of corn. Test results varied widely, with only a few labs, including Woods End Laboratories in Mt. Vernon, reporting a value for existing and potential fertility based on crop rotations and/or the biological activity in the soil. Most of the labs surveyed simply recommended large amounts of nitrogen for the heavy feeding corn crop.

While there have been many advances in soil testing in the interim three decades, the storehouse of potentially available nitrogen in soil organic matter encouraged through practices such as composting and cover cropping continues to be overlooked while synthetic nitrogen is still overprescribed and over applied, say Woods End scientists. The most recent environmental casualty, according to a report by the Agricultural Sustainability Institute at UC Davis, is nitrate contamination of drinking water. “Many fertilizer recommendations made no sense either economically or environmentally 30 years ago,” says Liebhardt, a retired ag science professor and founder of the sustainable agriculture program at UC Davis. “I think we could have sent a bag of 10-10-10 and we would still have gotten recommendations for more N, P and K. I hope it is not that way today, but change is very slow.”

Chapel Hill, North Carolina: Vermiculture Conference

North Carolina State University’s (NCSU) 13th Vermiculture Conference, November 5-6, 2012, offers training on earthworm farming and commercial vermicomposting. Scheduled topics include: Developing Markets for Vermicompost & Worms; Application Rates & Techniques; Extract (Tea) Preparation, Storage, & Uses; Business Strategies; Microbiology, Latest Research and Analysis Reports; How to Harvest, Store and Bag Vermicompost; On-Site Installations at Business, Institutions; Pathogen Minimization; and Technologies. For more information contact Rhonda Sherman, conference chair and NCSU Extension Specialist in the Department of Biological and Agricultural Engineering at (919) 515-6770; honda_sherman@ ncsu.edu. Details at www.bae.ncsu.edu/workshops/worm-conference.