Sally Brown

It seems as though people have started cooking. Not only is toilet paper in short supply in the supermarket, the baking aisle has a gaping hole where the flour is supposed to be. In this time of “Stay Home, Stay Healthy,” I’ve gotten more than one request for recipe sharing in my inbox. I have not been a good team player — though feel free to email me if you want a great recipe for Jamaican beef patties. Instead I’m going to share a different kind of recipe. One geared for those who are more comfortable “cooking” on a front-end loader than in front of the stove.

Long before “social distancing” was even a term, the City of San Francisco decided to upgrade the biosolids stabilization technology at one of its wastewater treatment plants. Instead of traditional anaerobic digestion to produce a Class B biosolids material, the city followed the lead of DC Water and opted for Advanced Thermal Hydrolysis prior to anaerobic digestion. This technology uses a combination of heat and pressure to treat the material coming from primary settling and secondary aeration before it goes into anaerobic digestion.

The process accomplishes two things: it gets hot enough to reach pasteurization, and it increases the digestability of the material so that more methane can be produced in the digesters. It also results in a lower quantity of Class A biosolids coming out the end of the process — something I lamented years back. However, what does come out is pathogen free. It is high in nitrogen, pretty high in water and not something you would want to put directly on your rose bush. Here appearance is the problem, not safety.

The City of Tacoma, Washington, has had a similar process for decades and has come to terms with how to market Class A cake in an elegant and cost-effective way. (See “Building Profitable Markets For Biosolids Products”). The TAGRO program, in cooperation with Washington State University, tested a range of “recipes,” if you will. These recipes included some type of carbon source and some mineral material. The city has ended up making two basic products. TAGRO Classic is a high nutrient material that is a quick mix of biosolids (40%), sawdust (40%) and sand (20%) by volume. It is great for topdressing a lawn. They also make TAGRO Potting Soil, which is a mix of biosolids (8%), aged wood (61%) and sawdust (31%) by volume. After blending, this product cures for a few weeks and is available in bulk or in bags. TAGRO regularly sells out both the classic and the potting soils — and the City of Tacoma has reduced its biosolids handling costs significantly.

Do As Tacoma Does

That sounded like a great idea to the folks in San Francisco, namely Ryan Batjiaka, a Bay area native, who was getting his Masters with me at the time. We approached Karri Ving, lead of San Francisco’s biosolids program, who was very interested in doing recipe testing. Ryan interned at TAGRO for a few months to understand its process and plan. He then went back to the Bay area to see what ingredients were locally available to make a San Francisco version of biosolids-based potting soil. Realize that locavores are not limited to cooking in kitchens. You can “cook” from your loader and still be a locavore.

Ryan looked for materials with a high C:N ratio that would fit through a 9.51 mm (half-inch) sieve. He identified a range of materials that sounded like they might make a nice mix, prioritizing feedstocks from waste streams over virgin materials to keep costs down and have a lower environmental footprint. Several sources of urban wood were found, including yard trimmings fines, yard trimmings and lumber fines. These materials are not unique to the Bay area. For more of a local flair, he found almond fines, redwood shavings and sawdust and walnut shells. Finally, with a desire to include some trendier ingredients, biochar and char made from walnut shells were located.

These potential ingredients were tested to identify any warning signs. Standard soil parameters were measured:

- Organic matter: high (>50%) is what you are looking for

- Electrical conductivity (EC): low (<2 dS/m) is best

- pH: a range (5-9) is acceptable

- Carbon:Nitrogen (C:N) ratio: >60:1 is best as the biosolids are high in N

- Bulk density (g cm3): < 1 g cm3. A level higher than that means greater potential for anaerobic conditions in the mix

- Moisture content: < 50%. Biosolids are relatively wet and you want something to help air flow through the mixture

These are all easy and relatively inexpensive parameters to measure. Moisture content and bulk density can be pretty well approximated by a trained eye. For this study, one of the materials was a little too rich (almond fines were 3.6% N with a C:N ratio of 14.7). Some were too salty (biochar and walnut char had EC of 11.8 and 40 dS/m respectively).

As this was a first-time recipe test, Ryan pretty much followed the blending basics that TAGRO uses. All feedstocks were mixed at volume ratio of 40% with Class A biosolids, 40% sawdust, and 20% sand. He also did a 50:50 mix of the yard and lumber materials with the biosolids, similar to the TAGRO potting soil. Finally, because the EC of the chars was so high, he reduced their percentage and made special “char mixes” consisting of 25% char, 25% yard trimmings fines and 50% biosolids. The mixtures were set to rest for 32 days.

How’d It Go?

As taste is a subjective thing, Ryan wanted to make sure to come up with a mix that was acceptable for a broad range of palates. His testing program reflected this.

No better way to turn customers off than with a smelly, moldy product. Ryan used panels to evaluate odor at several points during the curing process (days 1, 15 and 32) as well as to evaluate appearance immediately after mixing.

It turns out that with the Class A biosolids, there is pretty much nowhere to go but up. Ten of the 13 blends smelled better than the biosolids alone. Time also helped matters, with odor ratings improving for almost all of the blends, and the biosolids alone, over time. The two primary exceptions were the blend with walnut shell char and the blend with the almond fines. The pH of the walnut shell char mix was >10, high enough for ammonia to volatilize and offend the sniffers. The almond fines blend was too rich, too wet and got smelly and moldy by Day 32. Characteristics no one wants in a soil product for their garden. This was reflected in the CO2 evolution of the mix, a tool to measure mixture stability recommended by the US Composting Council’s Seal of Testing Assurance (STA) program, and a standard for soil testing. This blend gave off more than 8 mg of carbon as CO2 for each mg of organic matter. All other mixes gave off less than 5.5 mg CO2-C.

Appearance rated high right after mixing but for a few blends (almond fines), it deteriorated over time. We didn’t have the crew back to judge appearance a second time but if you start blending on your own, it is very important to have your mix still look lovely weeks after blending.

Soil Testing

Ryan generally followed the STA protocols to evaluate suitability of the different mixtures. The results were also compared to published soil specifications including the California Department of Transportation’s (Caltrans) guidelines.

Of the different variables tested, a few stand out as critical for recipe development: Electrical conductivity, pH, the C:N ratio, and CO2 evolution. Just like with food, if a soil is too salty (EC), the plants won’t want to grow. Again, just like food, different plants have different preferences or tolerances for salt. Seedlings, just like toddlers, are especially fussy. An ideal mix will have an EC<2 dS/m but plants can often tolerate <5 dS/M. Two of the mixes Ryan made were over that (the biochar and walnut shell char). With time and rainfall, the EC will go down.

Using less of these salty ingredients is another easy option. Same deal with pH, too high is too caustic. Here the walnut shell char mix came in at over 10, well above the 5-8 range that most plants prefer. As the organic matter in the mix mineralizes and as the mix gets exposed to air, the pH will decrease. This one was like a fine wine, needing time to age. If time is not on your side, then cut down on the char.

The C:N ratio is another factor — too low and the mix is likely unstable. That was the case with the almond fine blend (9.1). Get it over 12-15 and you are good. Get it too high and your plants turn yellow. The walnut shell mix had a C:N mix of 29, potentially not enough nitrogen for the plants to prosper. Finally, the stability is important. You may like raw cookie dough but plants like their cookies cooked. The almond fines mix was the one of concern here.

Plant Response

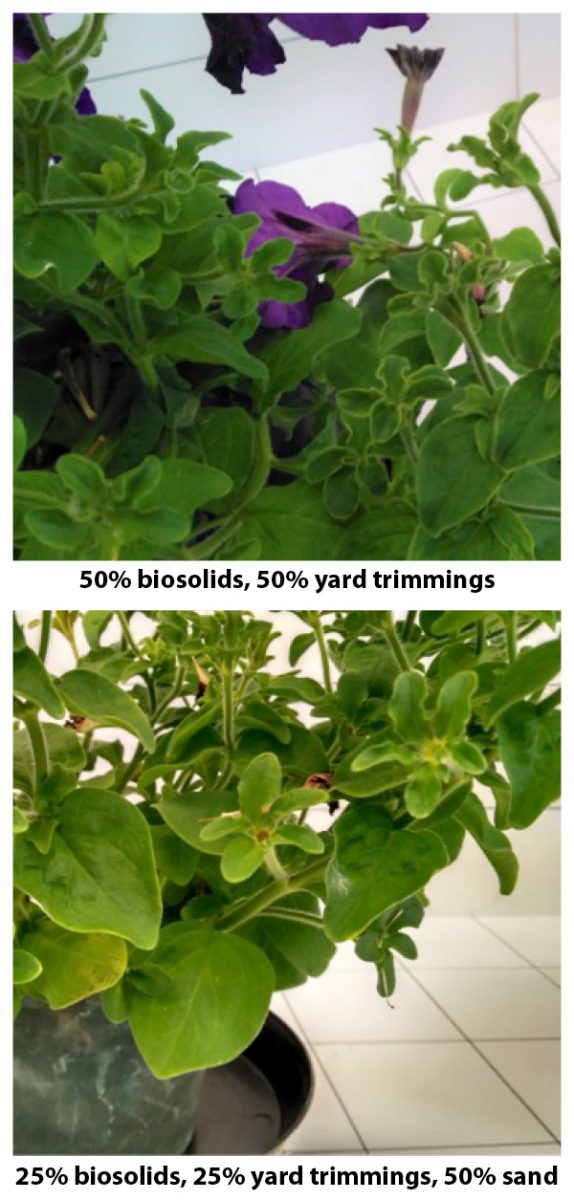

Plants are the ultimate test. Think of it as the Michelin star for your mixture. Ryan tested both seedling germination and plant response. Just like cooking for your finicky toddler, he looked at cucumber and radish germination as those are sensitive crops. Because Ryan is cooking for more of an urban audience, he grew petunias. Soil standards for a topdressing for field corn will require a different set of recipe testing.

The cucumbers and radishes germinated well for most of the mixes. Seedlings were set to germinate in 100% of the blends, rather than the more forgiving 50:50 mix of blends and commercial potting mix that are often used. Three factors lead to poor germination. If your mixes are too salty (EC), the pH is too high, and the decomposition too active (respiration per unit of organic matter), those seeds are not happy. The char, walnut shell char and almond fines mixes did not pass the germination test because of the reasons just stated. But not every mix needs to be used for germination. In many cases your potential customers are looking for something to spread on top of their soil, or to gently incorporate it in. Think of it as a thick layer of icing on a cake.

The test plants for the growth study were petunias. While petunias are not the typical choice for farmers, they are very popular for home gardeners. Ryan got baby petunias from a local nursery to use for the trial. He counted number of blossoms, weight of the plant and a shoot index. The shoot index is used as a measure of quality of the vegetation and is an average of the width of the plant and the height. The Betty Crocker Gold Standards here were the TAGRO Potting Soil, TAGRO Classic blend, and a food/yard trimmings compost produced using the Gore cover system.

I am very proud to say that many of the mixes met that standard. The yard trimmings, lumber fines and yard/lumber mixtures had more flowers than even the TAGRO Potting Soil. While the plants may not have been quite as big, they sure looked beautiful. The walnut shell char and almond fines mixtures did not hold up so well. I would argue that the seasoning on these was overhanded. Cut down on the char and you might come up with a real winner. Bake the almond fines (compost) or add some yard trimmings and you might have a real hit. The ingredients weren’t the problem; the recipes for these just weren’t quite right.

Ryan is now “cooking” professionally for the San Francisco biosolids program. They are currently working to consistently produce Class A materials in order to do some real-world recipe testing. This study shows though that making high performing blends with Class A biosolids is — while not necessarily easy as pie — something well worth attempting. In these times if your preferred test kitchen has a front-end loader, let your creativity fly.

Sally Brown, BioCycle’s Senior Adviser and long-time Connections columnist, is a Research Professor in the College of the Environment at the University of Washington. This article is based on work presented in Batjiaka, R. and S. Brown. Creating topsoils and soil conditioners from biosolids and urban residuals. J. Environ. Qual.