Nora Goldstein

Extended producer responsibility (EPR) has arrived in the compostable foodservice packaging space. Vegware is a compostable products supplier founded in Scotland and also active in the U.S. The manufacturer started partnering with the composting sector in 2010 to enable its caterer clients to access commercial composting. “Vegware has always wanted to provide a zero waste solution for the foodservice sector,” explains Eilidh Brunton, senior waste management consultant at Vegware. “We manufacture and market a certified compostable line of products and from the outset, we have worked with the waste sector to help customers access suitable composting.. That is not without its challenges, but from a producer responsibility perspective, it was one we wanted to take on.”

Trade waste collections for used Vegware are now available in 56 of the 100 largest cities across the United Kingdom (UK), covering 72% of the UK’s urban population. Frustrated by a lack of collections in its home turf, Vegware launched its Close The Loop collection program in Scotland in 2017, providing an EPR service.

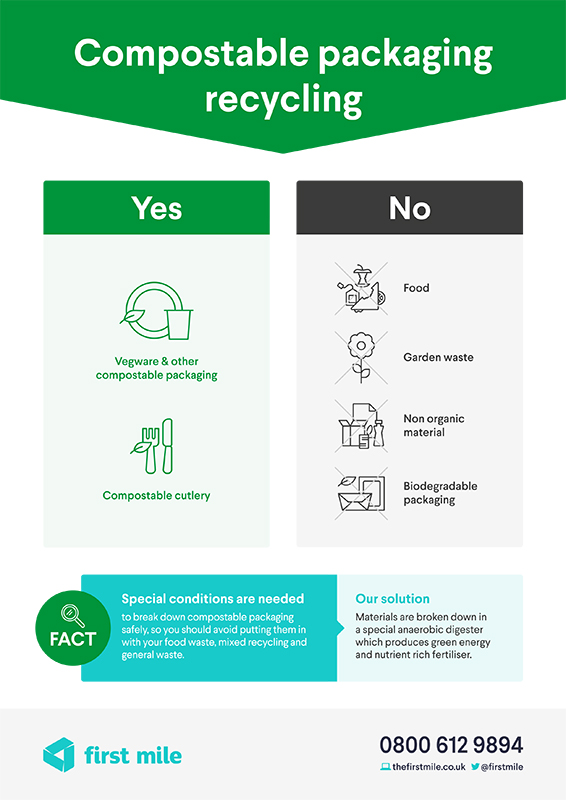

In the UK, food waste must be processed either at in-vessel composting (IVC) or anaerobic digestion (AD) facilities. Clients implementing a composting scheme often wish to combine food-soiled certified compostable packaging together with food waste for simplicity. However, AD is dominant in many UK regions, and commercial kitchens often already have a pure stream of food waste going to AD. Some larger foodservice sites choose to have two different organics streams: keep the “back of house” kitchen prep waste in their existing AD contract, and set up new “front of house” bins taking used Vegware and meal scraps that go to composting.

Vegware has hundreds of commercial customers choosing its products for their renewable materials, but either don’t set up a separate collection of those products or don’t have a trade waste collection going to suitable composting. The composting piece of the puzzle was aided in July 2018, when garden waste composting facilities in the UK that use open windrow composting were officially allowed to process certified compostable drinks cups and lids. “We now work with over a third of the 53 suitable IVC facilities in the UK, and are actively engaging with the waste sector to overcome any barriers,” says Brunton.

Close The Loop

Zero waste station at Dynamic Earth in Edinburgh, Scotland, an attraction that traces the history of the planet.

Vegware started Close The Loop to help more of its UK clients access commercial composting. “To gauge customer interest, we reached out to a waste collector in the central belt in Edinburgh that collects cardboard and inquired about its capacity to add collection of food-soiled Vegware products,” notes Brunton. “The plan was to offer clients using our products the collection service. The hauler had room on its trucks for dedicated “wheelie” bin(s) to collect the used products, swapping out a full bin with an empty one. It agreed to collect our materials.”

The pilot worked well and Vegware began to offer its Close The Loop service more widely. The filled 240L or 1100L bins are brought to a depot where the materials are aggregated and then transported each week to the composting facilities servicing that region. Waste collectors typically use box trucks with lift gates to load/offload the bins. Generators pay for the collection service, as they do for other materials collection.

Close The Loop collection service: (1) Wheelie bins are distributed to customers who collect (2) used, food-soiled Vegware compostable products. (3) Clean bins are swapped out for filled bins that are collected in box trucks. Photos courtesy of Vegware

“Drivers are trained to look out for contamination in the bins at the time of collection but there is no official sorting after leaving the customer’s location,” explains Georgia Budden, who works with Brunton and others on the Vegware team on collection program implementation. “Instead we work closely with the clients to minimize contamination through custom signage, training and engagement. We developed a ‘Five Steps To Zero Waste’ process to make sure the separation and collection system is established correctly.”

The five steps include:

- Switch all disposables to Vegware compostable alternatives to simplify the recycling for the customers, and reduce the risk of contamination.

- Identify the best recycling solution and label the bins.

- Communicate the system using posters and table talkers.

- Training and engagement — staff training is provided to ensure everyone knows which bin is for their location’s compostable packaging.

- Measure and communicate, including utilization of Vegware’s social media assets to promote the program.

First Miles’ national “postback” service where clients can collect used compostable products in a RecycleBox and ship them to a centralized location to be taken to a composting facility.

The company has near national collection coverage in Scotland and continues to launch new routes in other UK regions as it partners with local waste collectors and available composting facilities. Where collection isn’t available, Vegware has partnered with First Mile, a national “postback” service where clients can collect the used compostable products in a RecycleBox and ship them to a centralized location to be taken to a composting facility. “We also have a handful of clients who offer a ‘bring back’ program to their customers,” says Brunton. “For example, a small café in Edinburgh accepts the used products. After customers return them six times, they get a free lunch! The program also builds customer loyalty.”

In 2019, Vegware collaborated with Paper Round, a commercial recycling service, on a 12-month pilot to collect its compostable products from a dozen of Paper Round’s clients in London, including corporate offices that utilize catering services. Paper Round also offers food waste collection; those organics are taken to an anaerobic digestion facility.

The pilot included switching all disposable products to Vegware’s compostable product line. A waste stream audit conducted before the pilot began found that general waste comprised 30%, and standard coffee cups comprised 15%. Vegware compostable products being used at the time accounted for 35% of the waste audited. After the switch to all Vegware products and establishing separate collection, a second waste audit found the following: General waste-6%; Vegware-66%; standard coffee cups-0.3%. Food waste remained the same, at 14%, in both audits. A webinar on the pilot provides further details.

Paper Round launched the full-scale service in May 2020, in the midst of the pandemic, where many London offices it typically services were closed or on reduced work schedules. But the nearby Brighton part of its collection service is thriving. The compostable products are taken to the enVar IVC composting facility in Cambridgeshire. The material is shredded and then mixed with other feedstocks for a 7-week composting cycle. As many school and workplace caterers increase their use of disposables in response to COVID-19, Vegware is providing a way for foodservice to introduce more circular waste practices.