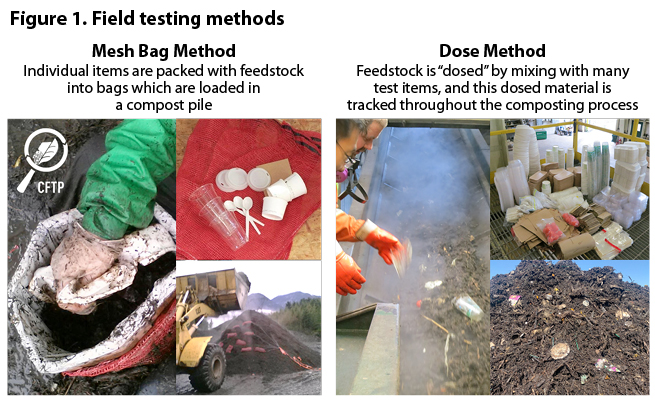

Top: Protocols used for field testing compostable items at operating composting facilities are the Mesh Bag (left) and Dose (right) methods. Photos courtesy Compostable Field Testing Program

Emily McGill

Compostable foodservice ware has been in development for decades. To fulfill its potential as a more sustainable packaging solution, product breakdown in real-world composting environments is essential. The Compostable Field Testing Program (CFTP) is a nonprofit research group that supports composters to field test certified compostable food packaging. Over the past 20 years, the CFTP has helped develop two major testing protocols in collaboration with composters, advisors, and industry experts: the Mesh Bag method and the Dose method. Both assess material disintegration but they differ in their ability to reflect how facilities actually process materials.

These two methods have been used for the data collected by the CFTP, which was made public in fall 2024 as described in Part I of this series. This article delves into the similarities and differences between the two field testing methods, how they impact product disintegration, and the pros and cons for each. The findings of the field testing will be covered in Part III of this article series.

Methods Overview

The Mesh Bag method (Figure 1, on left) has been in use and evolving since the 1990s. Individual test items are placed in mesh bags with 0.5 cm (0.04 inches) holes, allowing compost conditions, e.g., temperature, microbes, air and moisture, to interact with the material through the mesh while keeping test materials contained for easy recovery.

The Dose method (Figure 1, on right) was first trialed by BSIbio (a compostable products distributor and co-founder of the CFTP) and University of British Columbia researchers in 2014, and then again via the Closed Loop Partners’ Composting Consortium’s Disintegration Pilot conducted in 2023. In this method, a larger quantity of test items is mixed directly into the compost pile. The approach better reflects real-world conditions as products are not isolated within bags, but blended and processed with the feedstocks being composted.

Step-by-Step Method Comparison

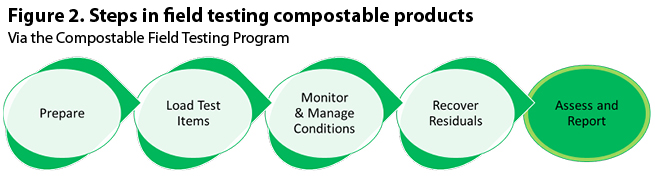

Both the mesh bag and dose methods share a similar approach: prepare to test; load test items into the compost operations; monitor composting conditions; recover residuals; and assess and report (Figure 2). However, key differences between the methods affect the type of insights they can provide, as outlined in this section.

1. Prepare to Test

Select the materials and items to be tested, choose which method to employ, and establish the timeframe and location for field testing.

- Mesh Bag: Select the test items, determine how many replicates to use (bags with the same mix of products), when and how they’ll be added to and removed from the compost pile, the total time frame for the test, and location for testing.

- Dose: Select the test items and decide what concentration to dose the feedstock at (e.g. 1%, 2%, 5%). Determine what quantity of feedstock to dose. Calculate the resulting quantity of test items, determine when and how they’ll be added to the compost pile, the time frame for the test, and how the results will be measured once the test is complete.

Key Considerations: Do you have the right number of items to test? Mesh bag requires adequate replication to gather enough data for analysis. Dose requires accurate calculations and proportionate sampling post-process to produce reliable results.

2. Load Test Materials into Compost

Introduce the test materials into active compost piles, exposing them to the facility’s standard processing conditions.

- Mesh Bag: Pack mesh bags with premixed/preground feedstock and the selected test items. Within the bags, surround test items completely with feedstock. Filled mesh bags are placed at a minimum 3-feet depth from all edges and ends of the compost pile. Mark the test area with flags and rope to avoid accidental disturbance.

- Dose: Separate test items and mix them directly (“dose”) into the compost feedstock. The dosed feedstock is incorporated into the compost facility’s regular operations in a way that enables it to be tracked throughout the process, e.g., the material is segregated or added to the end of an existing pile/row.

Key Considerations: Accurate placement in the Mesh Bag method, and thorough integration into feedstock in the Dose method, are vital to ensure meaningful results.

3. Monitor and Manage Composting Conditions

Environmental conditions such as temperature, moisture and oxygen are monitored throughout the active composting process and through curing, if curing is included in the test. Starting and end composting conditions are also tracked, such as bulk density, feedstock composition, maturity and stability.

- Mesh Bag: Ideally, temperature is tracked via remote data logging thermometers within the mesh bags. During the trial, the mesh bags may need to move, either to allow for turning, or between stages of active composting, and from active composting to curing. When required, mesh bags are recovered and placed in the new location.

- Dose: The dosed material is monitored throughout the trial, and if the material moves between stages of composting, it is moved in its entirety and not mixed with undosed material.

Key Considerations: Detailed monitoring ensures that physical and environmental variations in pile conditions are documented, enabling a better understanding of their impact on disintegration rates. Variations in key conditions such as temperature and moisture significantly influence disintegration.

4. Recover Residual Test Materials

At the end of testing, or at predetermined intervals during testing, the composted material is screened to one-quarter-inch either manually or mechanically. What passes through the screen is considered disintegrated, and the “overs” on top of the screen are hand-sorted to recover test item residuals. Residuals are retrieved and evaluated for disintegration. Observations include changes in weight and surface area.

- Mesh Bag: Mesh bags are carefully recovered from the pile. The contents are sorted manually using hand-held screens. Test item residuals are collected and grouped according to the item, and weights and photos taken, per bag. This method yields data for each individual test item.

- Dose: The entire mass of compost dosed with test items is screened mechanically. Residuals of compostable products are recovered from the resulting overs, either through subsampling and manually sorting, or sorting the overs in their entirety. Subsampling is not recommended at the current stage of the method’s development, as it relies on an assumption of the mixture being homogeneous to a degree which has not yet been studied. This method yields data grouped by item type.

Key Considerations: Assessment criteria and methods for gathering results must be consistent across trials to enable data comparability. In Dose testing it is important to account for the extra labor required in retrieving residuals from loose test items in the pile.

5. Assess and Report Results

The final stage involves analyzing how much remains of test items after composting — the percent of residuals remaining, in terms of weight and surface area. This data can then be aggregated and analyzed to identify patterns and draw conclusions about material performance and how variable compost operating conditions impact disintegration.

- Mesh Bag: Each test item’s residual values are compared to its original values to determine the percent residuals and its inverse, the percent disintegrated for each individual item.

- Dose: The data for all residuals of a particular item type is grouped together, and compared to the total initial values for all items of that type, evaluated on a mass, volume and surface area basis.

Key Considerations: Results should be interpreted in the context of both the method used and the facility’s specific operating conditions.

Role Of Standardization

The CFTP is collaborating within ASTM International on standardizing efforts for both the Mesh Bag and Dose field test methods. Standardization ensures consistency and reliability in testing, providing a framework for evaluating compostable products and better understanding the composting conditions that products are exposed to. Consistent science-based protocols have already proven valuable in helping manufacturers and composters better understand the complex interplay of composting conditions and product breakdown, which will also help to inform policy, regulations and certification.

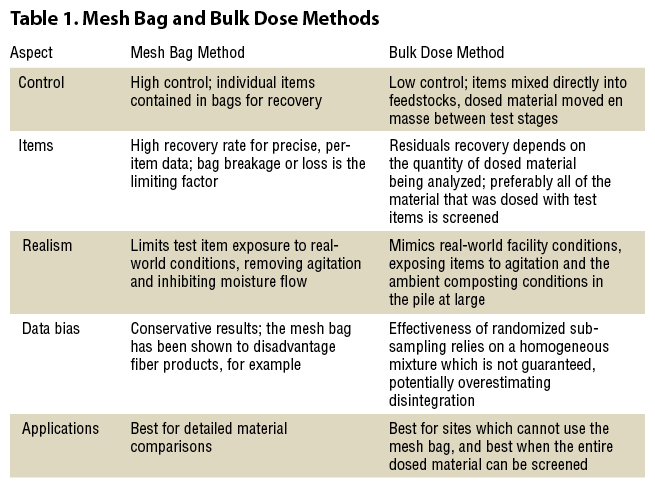

Pros And Cons Of Each Method

Table 1 summarizes the variables in the field testing methods. In the Mesh Bag method, the containment provided by the mesh ensures that each test item is exposed to composting conditions while remaining easy to retrieve. It also has the advantage of providing data for each individual item tested. The controlled nature of this method and item-specific data outputs allow for detailed comparisons across material types and environmental conditions. It is particularly effective for establishing conservative baseline metrics for some materials.

However, the mesh bag does prevent the test items from being exposed to agitation as the bags are removed and replaced before turning or moving the pile, and handling the bags adds some labor during testing. The mesh containment can also impact the free flow of moisture and microbes, which, when combined with the lack of agitation, can inhibit disintegration within the bag compared to the rest of the pile.

In the Dose method, test items are loaded directly into feedstock without containment. This simulates how compostable products are typically handled in operational settings, though it introduces variability in recovery. The dose method was originally developed to bring field testing to facilities which could not use the mesh bag method, e.g. sites with continuous agitation which would destroy mesh bags.

With its ability to better represent facility processing, dose testing has gained interest in recent years as an alternative to the mesh bag method for any site. Test items being directly exposed to the agitation and conditions of the pile avoids those limitations of the mesh bag method. However, the data the CFTP has gathered and received to date with the dose method has required massive quantities of test material and randomized subsampling. This subsampling relies heavily on the homogeneity of the dosed material and the ability to capture a representative portion of the residuals in sampling. Unintended or unexpected variation in the dosed mix can overestimate disintegration. At ASTM International, the latest updates to the method recommend screening all of the dosed material, rather than subsampling, which eliminates the concern of subsampling bias.

Building Confidence Through Methodology

Field testing bridges the gap between controlled lab-based disintegration and biodegradation and the dynamic realities of industrial composting environments. While laboratory tests simulate highly controlled composting conditions, field testing evaluates product disintegration amidst the variability of real-world composting systems, including differences in temperature, moisture, feedstocks, and processing times.

The continued evolution and refinement of these field test methods demonstrate the CFTP’s commitment to advancing compostable packaging research through robust, scientific approaches. By providing actionable data on material performance, these methods empower composters, manufacturers, and policymakers to make informed decisions, bridging the gap between sustainability goals and practical implementation.

As the composting industry continues to grow, field testing methodologies like these will play a crucial role in ensuring that compostable products contribute meaningfully to a circular economy. More information on the CFTP’s work is available on its website.

Part III of this article series will explore field testing results and their potential implications for the future of compostable packaging and composting.

Emily McGill is Program Director for the Compostable Field Testing Program (CFTP), via her role with BSIbio Packaging Solutions, one of the founding partners of the CFTP. Emily has directly facilitated or remotely supported over 20 field tests across diverse compost sites, and has used her experience to help lead the development of refined and standardized test methods under ASTM International.