Top: Harvest Cycle is a community composting project offered by Groundwork Rhode Island, and provides food scraps collection in Providence (RI).

Emma Sabella

Food encompasses 40% of all waste disposed in the United States, leading to the single biggest priority when it comes to diverting waste from disposal. The Center for EcoTechnology (CET) provides technical expertise to help local, state, and federal policymakers and businesses and institutions of all sizes develop and implement wasted food reduction and diversion programs across the EPA Food Recovery Hierarchy — from prevention to recovery and donation to recycling. CET has worked with three collection and composting operations, profiled in this article, which are living examples of food scraps recycling opportunities.

Bennett Compost

Bennett Compost, an urban food waste hauler and processor located in the heart of Philadelphia, Pennsylvania, was founded in 2011 with $100 and three small bins. Today, Bennett Compost serves 5,000 households and 50 commercial customers, keeping more than 80 tons/month of organic material out of the landfill.

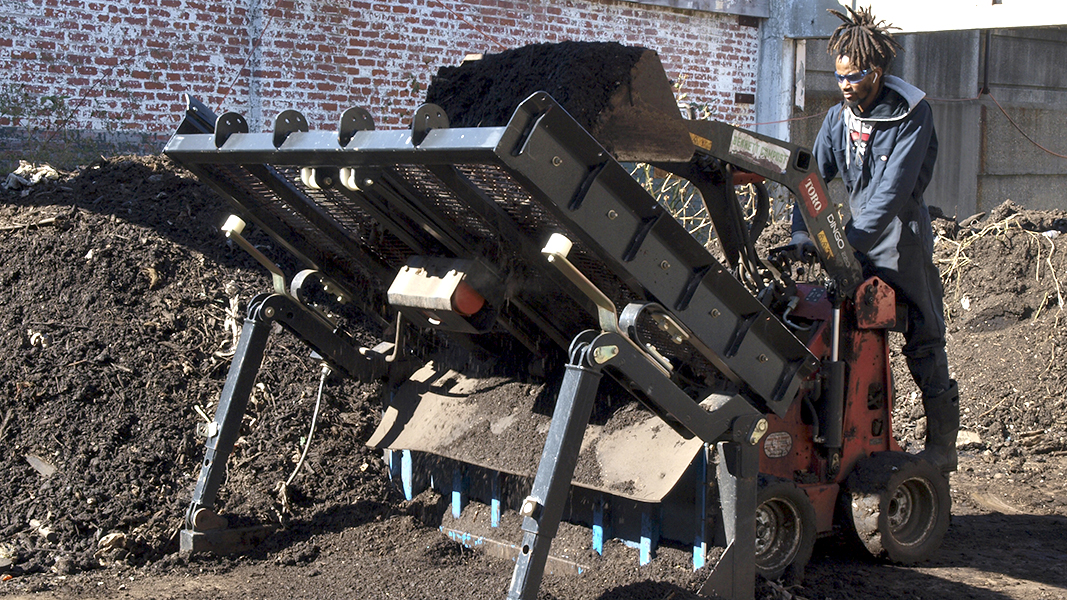

Bennett Compost recently moved from its 0.25 acre composting site to a municipal location. Composting equipment for its small urban footprint included a stand-behind mini skid steer loader and an improvised screen. Photos courtesy of Center for EcoTechnology

As demand for organics collection in Philadelphia increased, Bennett Compost reached the limits of its one-quarter-acre site’s processing capacity. The company collects 20 tons of material each week, but only had capacity to process 5 tons/week using aerated static piles. It partnered with two other sites in the area to process the remaining 15 tons/week of material. Being nimble, resourceful, and creative helped Bennett Compost scale up and divert more organics in a city with a population of 1.6 million.

In November 2020, Bennett Compost moved to a municipal site and will soon start processing materials generated from the City of Philadelphia. (It continues using other composting sites for processing until permitting is completed for the municipal site.) Fostering neighbor and community relationships and partnerships was paramount to the success of the company, and played a major role in the City’s decision to select Bennett Compost to operate the municipal site. Letters of support were received from local organizations, tours were provided to engage community groups such as Girl Scouts and local nonprofits, and Bennett Compost organized compost giveaways, and participated in community cleanups.

Harvest Cycle

Harvest Cycle is a community composting project offered by Groundwork Rhode Island, a nonprofit organization based in Pawtucket with the mission of creating healthier and more resilient urban communities through environmental sustainability and economic opportunity. Harvest Cycle collects food scraps by bicycle from more than 450 residences and eight businesses throughout Providence and processes the material at its community garden.

Harvest Cycle does not take putrescibles (meat, dairy, etc.) and is under the capacity cutoff of 25 cubic yards (cy) of material at a time, so no state permit is required for its composting operation. As a bicycle-powered organics hauler, the nonprofit is extremely efficient, and intentional about its pick up route. The model enables riders to serve 30 to 40 customers each day, without having to pay for gas and using fossil fuels. Customers outside of designated pick-up zones are encouraged to drop off food scraps at one of five different collection sites.

The bicycle-powered organics hauler organizes its collection routes so that riders can serve 30 to 40 customers each day.

The community garden composting site has seven 1.5-yard bins to process the food scraps, which are mixed with wood chips, leaves, and yard trimmings twice a week. Using shovels, pitchforks, and wheelbarrows, the material is removed from the bins and turned onto tarps, mixed, and then shoveled back into the bins to decompose. Other than a gas-powered auger used to help turn the material in cold winter months, all on-site labor is done by hand by a current crew of five.

The operation has many opportunities to recognize and pick out contamination. Bikers pick up food scraps in one 5-gallon bucket at a time, making it easy to spot any obvious contaminants. These are picked out and left in the customer’s bucket. Contamination that makes it on-site is pulled out by hand during processing. All customers receive an onboarding email when they sign up with a list of what items are accepted, and every email includes a list of the most persistent types of contamination to avoid (stickers, produce ties, “compostable” plastics). Harvest Cycle noticed that sometimes customers are confused about why some compost operations take meat and dairy and others do not. Educating customers on why some materials are accepted at certain sites and some are not is key to preventing contamination.

Harvest Cycle operates in an area where there is high demand for food scraps collection. However, due to space constraints and lack of funding, it needed to find creative ways to expand. For instance, it partners with four local community gardens to process additional material on their land in exchange for nutrient rich compost. Each garden is provided with several 1.5 cy compost bins. Three sites are open for drop off at all times and one site is open during business hours. Residents and businesses can sign up with Harvest Cycle to drop off their food scraps in the bins as often as needed. Customers are welcome to purchase a 5-gallon bucket for food scraps collection when they sign up for the drop off program. (The fifth drop-off location is at Harvest Cycle’s site.)

To keep even more organics out of landfills, Harvest Cycle was awarded funding to remediate a brownfield site to expand its operation. This new location will include a concrete slab and bays for storing materials and will enable Harvest Cycle to process 7 to 10 tons/week of material, servicing the equivalent of one city trash route. Harvest Cycle intends to purchase an in-vessel composting system and is planning to apply for a medium-scale permit that allows it to accept meat and dairy. Groundwork Rhode Island operates an environmental job training program from which Harvest Cycle hires staff. Graduates of the program will be hired to operate the new facility. Finished compost will be sold to urban farms in the neighborhood, keeping the benefits close to home. The site also will be used for school field trips, and to host weekend volunteer days and composting workshops.

Harvest Cycle’s future vision is to have frequent aggregation points or processing locations across town, so that all organic waste in Providence can be picked up by bicycle. Trucks will pick up collected food scraps from the aggregation points. This model positively impacts the climate and reduces noise and air pollution for neighborhood residents. Ideally, some of these aggregation points can eventually become processing sites, further reducing vehicle miles traveled, and keeping compost in the neighborhoods where it is produced as a resource for the community.

GoZERO

GoZERO Compost Services, located in central Ohio, is a food scraps composting services provider. It collects 82 tons/month of organics that are composted at several facilities, including Andre Farms in Wauseon, Ohio and London Correctional Institution in London. GoZERO offers community food scraps drop-off stations, commercial organics collection, and provides and services organics carts for venues. The composting sites used by GoZero process food scraps, BPI certified compostable plastics, paper, wood, and other carbon-based bulking agents.

GoZERO is the service provider to multiple municipal food scraps drop-off sites in the Columbus, Ohio area. The Solid Waste Authority of Central Ohio provided funding to these municipalities to establish the drop-off locations and work with a collection provider. Based on its experience, GoZero is establishing best practices for commercial composting that are reproducible and scalable. It intends to share these best practices to help solve food scraps related challenges in Ohio and beyond.

Emma Sabella is a Program Specialist with the Center for EcoTechnology. As detailed on CET’s Wasted Food Solutions website, a business or institution may be eligible to receive no-cost waste expertise if they are seeking to reduce and recover wasted food. The work is possible thanks to strong partnerships with state and federal agencies, nonprofits, sponsors like the U.S. EPA, and the food rescue organizations, haulers, and processors that bring the marketplace to life.