BioCycle October 2012, Vol. 53, No. 10, p. 55

Filter Sock Earns Biobased Label

Filtrexx has earned the USDA Certified Biobased Product (UCBP) label for its SiltSoxx™ sediment and erosion control products. The UCBP label is issued under the USDA BioPreferred® program, which promotes increased purchase and use of biobased products. The UCBP label verifies that the product’s amount of renewable biobased ingredients meets or exceeds prescribed USDA standards. Biobased products are goods composed in whole or in significant part of agricultural, forestry, or marine materials. Filtrexx SiltSoxx have been certified as 100 percent biobased. “We’re seeing widespread adoption of SiltSoxx as a BMP in storm water management because of their ease and performance,” says Filtrexx CEO Rod Tyler. All biobased amount claims are verified by independent labs and monitored by the USDA. www.filtrexx.com

NRC And RONA Join Forces

The National Recycling Coalition (NRC) and the Recycling Organization of North America (RONA) have signed a letter of agreement to join forces and reorganize under one umbrella — the North American Recycling Coalition — pending approval by both boards. According to a press release announcing the merger, the NRC acronym will be retained. Combining NRC and RONA’s assets and resources as well as state and provincial affiliations will create a stronger presence in the recycling arena. “I am thrilled that we will now be moving forward with a unified voice for recycling,” said NRC president Mark Lichtenstein. nrcrecycles.org

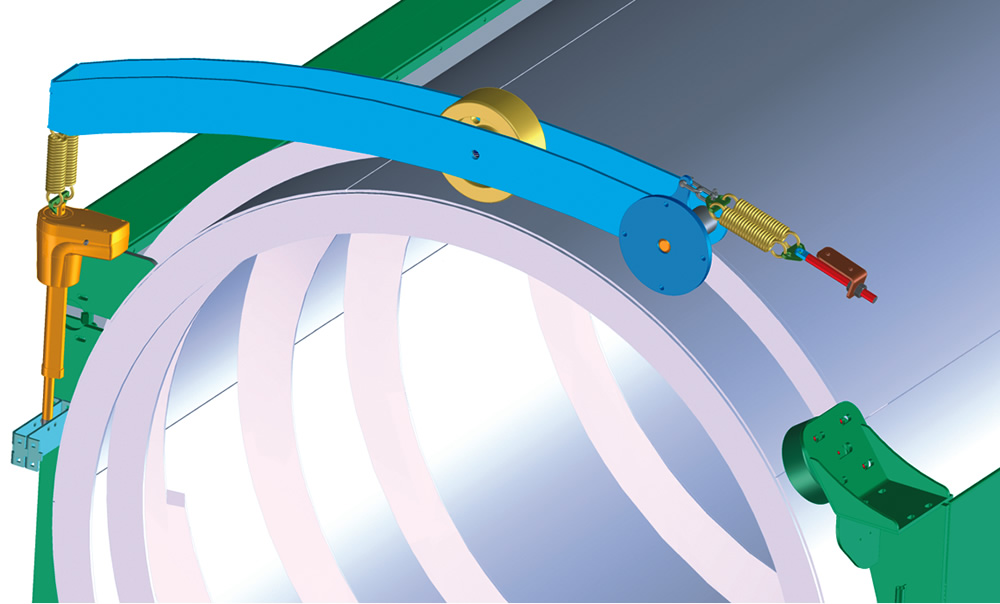

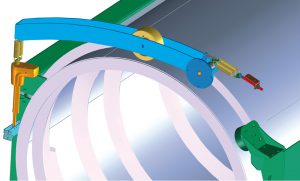

Wheelgrip For Drum Screen

The new Cribus series of drum screens from Komptech comes with patented “Wheelgrip” technology. The larger two models, Cribus 3800 and 5000, have a drive system consisting of four electronically driven wheels and a fifth wheel that provides downward pressure if the machine senses drum slippage. Because there are no chains and sprockets, changing between drums is reduced to 5 minutes, notes Komptech, adding that the Wheelgrip system also offers much more flexibility in drum speed — adjustable between 8 and 20 RPM, allowing the customer to adjust the speed for varying materials. www.kompechusa.com

Composting Expansion

Silver Springs Organic (SSO) recently held a grand reopening of its composting facility in Rainier, Washington, doubling processing capacity from 60,000 tons/year to 120,000 tons/year. Primary feedstocks composted are manure, food waste and yard trimmings. It is using the Engineered Compost Systems (ECS) high-rate aerated static pile technology for the active phase of processing, as well as the ECS RF TeleProbe and server based controls. SSO also built about 5 acres of roofing that separates storm water from condensate and leachate. www.compostsystems.com

Compact Biogas CHP Systems

To accommodate modular compact biogas digesters that process smaller volumes of organic wastes, 2G CENERGY® is offering compact combined heat and power (CHP) biogas units. Its new 2G filius® biogas CHP is a completely containerized, connection-ready system optimized for smaller biogas facilities. The modular standard size is 20 feet and is available in nameplate capacities ranging from 50 kWh to 150 kWh.

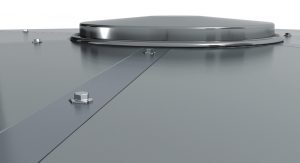

New Dome Design

CST Covers, a division of CST Industries, Inc., introduced an innovative flush batten aluminum geodesic dome design for its engineered cover technology. OptiDome™ features a Double Web I-Beam for strength and stability, plus patent pending batten seal technology that eliminates environmental exposure and UV degradation. CST notes that the new hub cover technology eliminates the need for exterior sealant at the nodes. www.cstcovers.com