Top: Compostable bags used for food waste collection. Photos by Massimo Centemero

Massimo Centemero, Marco Ricci and Alberto Confalonieri

Recycling organic waste into compost is essential for establishing modern, sustainable systems focused on transforming waste into valuable resources. When collected separately, organic waste significantly reduces the fermentability of remaining waste. This minimizes the necessity for intensive predisposal treatments and decreases greenhouse gas emissions associated with landfilling. Furthermore, because organic waste constitutes a substantial portion of municipal solid waste (MSW), less disposal capacity is required for residuals. Thus, promoting organic waste recycling not only supports environmental goals but also optimizes waste management efficiency.

Italy is currently one of the top-performing European Union (EU) member states in recycling municipal solid waste (MSW) generated in urban areas. Following consistent improvements, around 65% of all MSW generated in 2022 was separately collected and sent to materials and organics recycling facilities. That same year, the average MSW production per inhabitant was 434 kg (957 lbs). Italian municipalities have systematically committed to the separate collection of organic waste from both households and commercial activities (due in part to a 2022 law requiring separate collection of organics). This includes a specific scheme for garden and park waste (yard trimmings) utilizing bring sites (drop-off) or pay-as-you-throw (PAYT) collections at the doorstep, along with frequent and potentially doorstep collection of food waste. Notably, due to the efficient organization of food waste collection, the amount remaining in the residual waste fraction is often below 10% fresh matter (f.m. or wet weight, or “as is”). Currently, organic waste makes up almost 40% of the 65% of all separately collected MSW in Italy sent to recycling, significantly driving the overall separate collection of MSW.

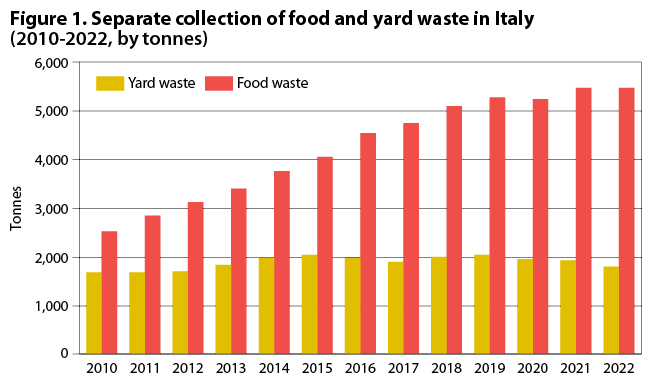

Updated official data for 2022 indicate that 7.2 million metric tons (tonnes) of organic waste (equivalent to 123 kg per capita) were collected by Italian municipalities, with about 75% consisting of food wastes. The collection of food wastes has seen a significant improvement, having doubled between 2010 and 2022, while yard trimmings collection increased by less than 20% during the same period (Figure 1). The Italian Composting and Biogas Association (CIC) estimates that currently about 90% of Italy’s population is connected to source separation schemes for food waste.

Single-use bags and liners become essential when households are required to collect most of their kitchen waste, including cooked food leftovers and partially liquid food residues. Since the 1990s, local authorities and waste collection companies in Italy have been providing households and commercial producers with paper or compostable plastic liners to encourage proper sorting of kitchen waste. This is due to its fermentable nature, high moisture content, and tendency to release odors and leachate if stored improperly. In 2010, the use of compostable liners became mandatory to prevent conventional plastic bags from contaminating composting and biogas facilities, thus avoiding the presence of plastic fragments in compost and soil.

How Compostable Plastics Behave In Industrial Composting

Globally, Italy became the first country worldwide to establish, in 2020, an extended producer responsibility (EPR) scheme for compostable plastic packaging, called Biorepack (see box). Prior to Biorepack’s formation, CIC conducted a national survey in 2017/2019 to evaluate the disintegration of compostable plastics within its members’ facilities. The survey included 27 composting and combined anaerobic digestion (AD) and composting plants, which collectively treat almost 3 million tonnes/year of organic waste; kitchen and yard waste comprise 96% of the total input.

The national survey examined the movement of plastics and other contaminants through the treatment processes of each plant, assessing the quantities that are separated (ending up in process rejects), recirculated (with the bulking agent), or incorporated into the final compost.

Laboratory analysis by CIC of the plastic fragments detected in the compost samples collected showed that none of the fragments were compostable plastic polymers, demonstrating that the recycling process successfully handles these materials at industrial facilities.

Focusing on food waste, which is expected to contain the largest share of physical contaminants, the amounts analyzed contain 3.1% f.m. of conventional plastic contaminants, 2.1% f.m. of other contaminants (such as glass and metals), and 3.7% f.m. of compostable plastics. Of the contaminants, about 90% of the conventional plastics are films, and packaging accounts for about 50% of all detected plastics. In comparison, yard trimmings had relatively low contamination levels, not exceeding 1% f.m.

Usually, preprocessing of food wastes (e.g., shredding, depackaging, screening, etc.) is effective in reducing the contaminant content of plastics to less than 2% in the input mixture undergoing biological treatment. Measurements at the facilities also enable measurement of the “dragging factor” during contaminant removal. The dragging factor is due to the sticky nature of organic waste which tends to “glue” onto the plastics, so when equipment removes plastics (and other) contaminants it also removes part of the organics. This increases the total amount of rejects during the recycling process; on average, the dragging factor is 2.75 — for example, 4% of physical contaminants result in approximately 12% final rejects when taking into account the organics adhering to the contaminants. The dragging factor rises with increasing levels of contaminants, causing significant reductions in the quantity of organics recycled, as well as an increase in the cost for disposing rejects and lower revenues from compost sales.

In this context the effective disintegration of compostable plastics during the recycling process is crucial to prevent physical and visual contamination of the final compost. During CIC’s national survey, compost was sampled at all facilities, and various contaminants were detected and measured. For all compost, the total contamination level results were significantly below the 0.5% dry matter (d.m.) limit set by the Italian Fertilizer regulation. In addition, laboratory analysis by CIC on the plastic fragments detected showed that none of these fragments are compostable plastic polymers, demonstrating that the recycling process successfully handles these materials at industrial facilities.

Based on the survey evidence, the CIC recommends limiting pre-screening or depackaging before organics processing to minimize the loss of organics due to the dragging factor. Consequently, a “clean” feedstock with a low percentage of contaminants can be directly treated at composting facilities. However, in the case of combined AD and composting, a pretreatment step is unavoidable; this step ensures that the feedstock is adjusted in terms of moisture and dry matter content and sorts out physical contaminants, which could potentially damage the equipment during the AD process.

Bioplastics And Compost In Italy

According to Italy’s National Waste Legislation, compostable plastics, including bioplastic carrier bags, fruit and vegetable packaging, plates, glasses, and disposable tableware made of compostable material, can be collected with food waste only if they are certified according to the European harmonized standard UNI-EN-13432. Biorepack and CIC have established a national survey program involving around 700 waste composition analyses per annum to continuously assess the amounts of compostable plastics and contaminants collected within food waste collection. These efforts are part of a broader strategy to enhance the effectiveness of compostable plastic recycling, ensuring that the materials collected do not compromise the quality of the compost produced. By adhering to the stringent UNI-EN-13432 standard, Italy aims to maintain high recycling rates and minimize contamination in composting processes, supporting both environmental sustainability and the circular economy.

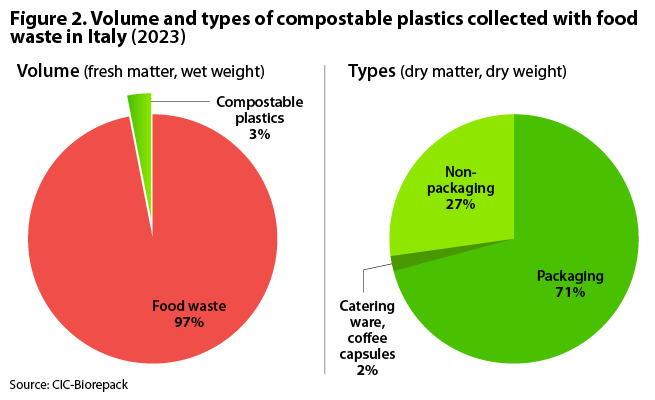

Thanks to this cooperation, updated data from Biorepack for 2023 show that about 83% of all compostable plastics packaging collected jointly with food waste are effectively included into the biological recycling process (i.e. anaerobic digestion, composting or both), while 17% are ending up in the reject flow. From a quantitative point of view compostable plastics represent almost 3% f.m. of all food waste collected (about 5.5 million tonnes) and consist mainly of packaging waste followed by nonpackaging items (such as liners for food waste collection) and minor quantities of rigid packaging such as catering ware (i.e. cutlery, plates, cups) and coffee capsules (Figure 2).

Compost Production And Use In Italy

About 1.9 million tonnes of compost are produced annually at composting and combined AD and composting plants in Italy.

Over the past 15 years, Italy’s waste treatment facilities have not only expanded their capacity but also transitioned from basic composting technologies to a more advanced approach, incorporating a pre-digestion step that produces biogas from easily degradable organic matter, followed by a post-composting step for the digestate. This combined treatment offers several advantages, such as producing biomethane, a renewable energy source, and creating a solid organic fertilizer (compost) that is easier to handle, store, and market. This innovation ameliorates the sustainability of the overall recycling process. Additionally, the composting phase enables recycling of compostable items like liners, bags, and packaging.

About 1.9 million tonnes of compost are produced annually at composting and combined AD and composting plants in Italy. Of that total, approximately 65% is produced at composting only facilities, and 35% is produced at combined AD and composting plants. Compost is recognized as a product and, according to Italian Fertiliser Legislation (Dlgs 75/2010), compost derived from food waste is classified as a soil improver that can be used in both conventional and organic farming. About 35% of all Italian compost carries CIC’s voluntary “Compost Quality CIC” label, which enhances user confidence and acceptance.

A detailed analysis of the compost market in Italy, conducted by CIC for CY2021, reveals that the market is predominantly local, with most sales occurring near the facility or within the same district or region to minimize transportation costs. The analysis found that 80% of the compost from food waste is sold directly to final users such as farmers at an average price ranging from €6/tonne ($6.40/tonne) when sold in bulk, to €150/tonne ($161/tonne) when sold packaged. CIC expects the compost market to reach 2 million tonnes by 2026.

Massimo Centemero, a leading European expert in composting and compost application on soil, is the Managing Director of CIC and the vice-chair of the European Compost Network (ECN), which serves as the umbrella organization for compost and biogas entities across Europe. Marco Ricci is senior expert at CIC, and leads the Compostable CIC certification for compostable items. He also serves as the vice-chair of the ISWA Working Group on Biological Treatment of Waste and is a leading expert in planning strategies for organic waste treatment and designing collection schemes. Alberto Confalonieri is chair of the technical committee of CIC, and has a significant experience in assessing the performance of both compost and anaerobic digestion facilities; in recent years he follows the development of biomethane production from organic waste.