Analysis clearly shows waste-to-energy facilities are not the best environmental option for managing leftover waste, pointing instead to Material Recovery, Biological Treatment.

Eric Lombardi and Kate Bailey

BioCycle July 2013, Vol. 54, No. 7, p. 48

The bulk of solid waste disposed today can be recovered for reuse, recycling and composting, with markets for around 90 percent of what is thrown away. Therefore it makes no sense to continue building the large waste disposal infrastructure of the past. “On the way to zero,” a community now needs a mechanism for responsibly handling the remaining 10 percent, (i.e. the “leftovers”), which is the mixed waste material that remains while a community is transitioning to a full-throttle, comprehensive source separation program that has Zero Waste as the ultimate goal. Sinking hundreds of millions of dollars into building a disposal facility designed to handle a large, steady flow of mixed waste is about the fastest way for a community to put the brakes on its progress toward Zero Waste because it steals funds and tons away from diversion.

This begs the following question: Is there a smart infrastructure investment a community can make to manage the relatively small, post-recycling/composting leftovers that supports a continued progression toward Zero Waste and minimizes the harm to public health and the environment? The waste-to-energy (WTE) industry has been increasingly aggressive in claiming that using the leftover mixed waste to create energy is the preferred method for handling nonrecycled materials. Anthony Orlando, president and CEO of Covanta Holding Corp., one of the world’s largest owners and operators of waste-to-energy infrastructure, was recently quoted in Waste & Recycling News as saying: “We think [our clients should] absolutely [be] pushing recycling, but then looking to do the best with what´s leftover after that recycling. And clearly, the answer, whether you listen to the [European Union], the U.S. EPA or any kind of policy initiative, the best environmental answer after you’ve recycled is to convert what’s left over into energy.”

A New Kid On The Block Named “MRBT”

A common misconception is that disposal is an either/or question — either a landfill or an incinerator. But this isn’t true in practice because incinerators also need landfills to dispose of their ash and other items that don’t burn well. WTE facilities on average send 10 percent of their feedstock by volume to landfills (up to 25 percent by weight), according to the U.S. EPA. So there is no such thing as “zero waste to landfill,” a statement sometimes made by companies about achieving zero waste. In essence, incinerators are really just “pretreating” leftover waste before landfilling.

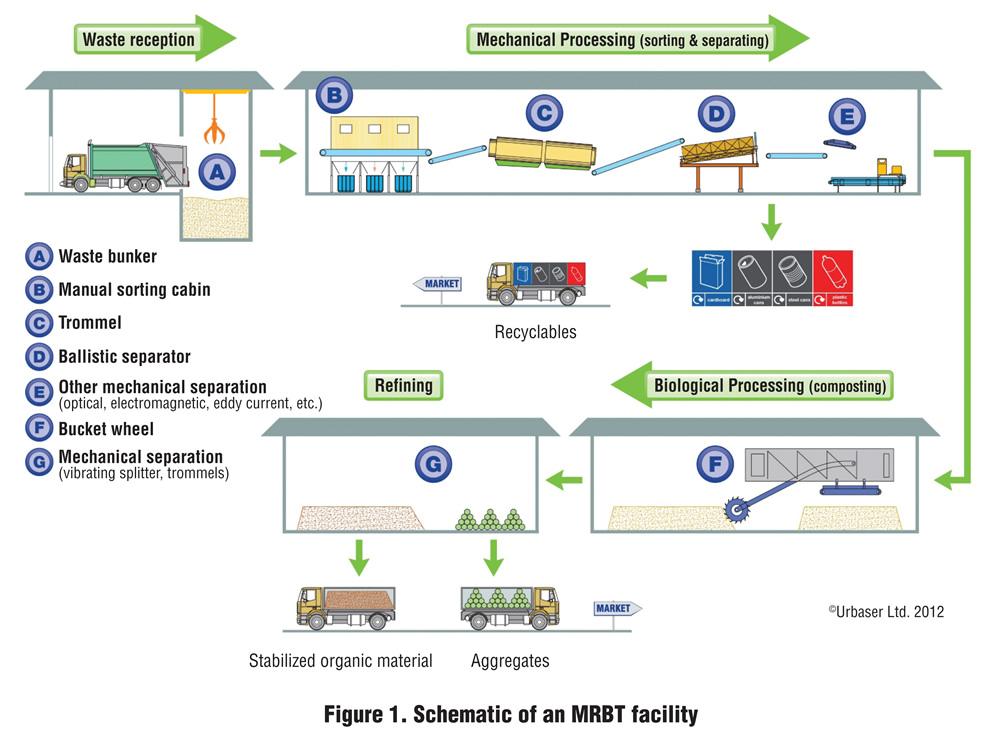

In the U.S., around two-thirds of MSW discards are still landfilled or incinerated; Europe, however, has a third option for the disposal of leftovers. The system — known as mechanical biological treatment (MBT) — involves sorting the leftover mixed waste for any easy-to-grab, easy-to-market recyclables such as plastic bottles and cardboard, and then stabilizing the biodegradable portion of the waste so that it doesn’t create landfill gas when buried, greatly reducing the environmental impact of landfilling. Eco-Cycle’s study thus analyzed the three most dominant disposal technologies in the world today — landfills, incinerators and MBT. For the study, the third option was renamed Material Recovery, Biological Treatment (MRBT) to draw attention to an increased focus on sorting out recyclables and other dry items (Figure 1).

Analysis Of Scenarios

Five scenarios were analyzed: Two landfill options (one with 80 percent landfill gas (LFG) captured and used for energy production and one with 40 percent); one Waste-To-Energy option (mass-burn system); and two MRBT scenarios (one with “high recovery” of recyclables and no LFG capture and one with “low recovery” of recyclables and no LFG capture.) The assumptions regarding LFG capture rates and recovery of recyclables from MRBT are meant to be conservative and reflect general industry consensus to avoid any bias. However, we recognize that LFG capture rates are controversial and so we picked a range for gas collection efficiencies that reflects the large uncertainty about how much LFG is actually captured over the life of the landfill. Our goal in picking this range was in the hope that anyone associated with the landfill industry would read our study and not feel like we had tilted the playing field against them. And for the WTE option, we chose the typical mass-burn facility with energy recovery. Thermal conversion technologies, such as pyrolysis, gasification and plasma arc, were not considered in the analysis because no commercial scale facilities with real emissions data are in operation in the U.S. The authors want to emphasize that this study is a technical assessment of the lifecycle environmental impacts using the best real data that could be located.

Using the lifecycle analysis tool developed by Morris — called MEBCalc™ or Measuring Environmental Benefits Calculator — the study compared these five disposal scenarios across seven (7) lifecycle environmental impacts: climate change, acidification, eutrophication, respiratory diseases, noncancers, cancers and ecotoxicity. MEBCalc is based on pollution data from the EPA’s TRACI model. (A full description of these categories and the assumptions used in the MEBCalc model are in the full report.)

The authors chose to model the City of Seattle for two reasons: its successful, cutting edge recovery programs, and its great data on its leftover waste. Seattle households recycle and compost an impressive 71 percent of their discards, leaving 29 percent for disposal (the leftovers). These leftovers include food waste (30%), pet waste and diapers (26%), followed by some paper (12%), plastic (4%) and textiles/clothing (3%). Many of these items could be recovered, particularly food waste and paper that could be captured for composting as Seattle’s curbside composting program matures. But they are, at least for the short term, leftover waste that needs to be disposed. The study modeled the materials flow of that leftover stream through the five disposal options to find the most environmental one.

MRBT Has Least Impact

The analysis identified the MRBT system to be the best choice for a community to dispose of its leftovers for the following reasons: Recovers the greatest amount of additional recyclables; Stabilizes the organic fraction of the residuals, thus preventing generation and release of landfill methane; Reduces the amount of material to be disposed in a landfill; Minimizes the negative environmental and public health impacts of landfilling leftovers compared to the other disposal alternatives; Can operate as a “dual-purpose facility” that also supports source separated recycling/composting collections; and Identifies other nonrecyclable items in the trash before burial for future “producer redesign” opportunities.

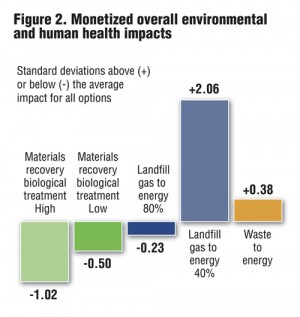

MRBT had the lowest environmental impact across five of the seven categories assessed, and the lowest overall monetized score. Since it’s difficult to objectively say if it’s more important to reduce greenhouse gas emissions versus cancer risks versus water pollution, economists use a technique called monetization to apply a dollar value to environmental impacts to make a more “apples to apples” comparison. “Monetization provides a method for evaluating trade-offs between the different types of environmental impacts and is a standard approach within the field of environmental economics,” explains Morris. “The benefit of monetization is that it summarizes and aggregates the environmental impacts into a single indicator for each management option.”

Figure 2 shows MRBT had the lowest overall environmental and human health impacts. The results are displayed using standard deviation, which summarizes the relative impacts of each leftovers management approach as it compares to the average impact. Any impact above the midline is “relatively worse” when compared to the other options. Likewise, impacts below the midline are “relatively better” in terms of lower environmental impact. The full report contains the raw scores for each disposal scenario across each environmental category.

Infrastructure For A ZW Future

MRBT facilities have another important and valuable quality — they’re not threatened by higher recycling rates because they can be “dual purpose” systems that can process both mixed waste and source separated discards. This is a very critical point because a Zero Waste community will have an ever-decreasing amount of mixed waste per capita as more discards are recovered through source separation or avoided by reuse and waste reduction programs.

WTE facilities and landfills, on the other hand, depend upon a minimum amount of waste coming through the front door in order to be financially viable. This is especially critical for WTE facilities as they usually negotiate a “put or pay” contract where a minimum number of tons of mixed waste are guaranteed, which makes the community liable for supplying a large number of tons for an extended period, often 20 or more years. WTE facilities cannot be a bridge to a Zero Waste future when their economic and operational model is dependent upon a reliable, high quantity flow of leftover waste.

Communities need to invest in more infrastructure that supports increasing diversion rates. MRBT facilities can support a Zero Waste community because they are not dependent upon a constant feedstock of mixed waste and can easily shift away from processing mixed waste and expand the processing of clean source separated discards as a community improves its recycling and composting. For example, the MBT facility in Perugia, Italy began with the biological treatment of mixed waste but now also composts source separated organics to produce high quality soil amendments. This type of dual-purposed facility is a smart capital investment and the bridge to a Zero Waste future.

In addition, experience in Europe shows MRBT infrastructure can be built and operational in the U.S. in a shorter timeframe than landfills and incinerators, and can be modular in size to help communities manage leftover waste more locally. The shorter lead time is a result of less public opposition and more political support for these technologies compared to larger, less flexible technologies like incineration. Plus, the MRBT facility can be built at an existing landfill site.

Higher Recovery Rates

As a “preprocessing” system before landfilling, MRBT offers one more significant benefit: It reduces the total amount of waste landfilled. The MRBT system modeled for Seattle increased the community diversion rate up to 87 percent — 71 percent recovery from source separated recycling and composting, and another 16 percent diversion from MRBT, including recovery of additional recyclables from mechanically sorting the leftovers and the moisture and carbon reduction from the aerobic composting of the leftovers. This remarkably high recovery rate demonstrates that MRBT can reduce leftover waste into the landfill to the same levels as an incinerator while still supporting source separation as the highest and best priority.

Based on the study’s findings, MRBT is the correct choice for any community with limited disposal capacity that is either considering an investment in an incinerator or needing to increase the life of its existing landfill. MRBT is a good match for communities already committed to source separation and looking to take the next step to reduce their environmental impacts to meet Zero Waste or sustainability goals. But it is not the first step for a community with low diversion rates and low participation in recycling and composting programs. These communities should focus on the 3Rs (reduce, reuse, recycle) and getting valuable resources out of the waste stream in the most environmentally sound way: source separation.

The Eco-Cycle analysis clearly shows WTE facilities are not the best environmental option for managing leftover waste. After maximizing source separated recycling and composting, communities looking to minimize the environmental impacts of their remaining waste should pursue an MRBT system. It is a smart capital infrastructure investment that provides disposal services while supporting ever-increasing recycling and composting.

Eric Lombardi is Executive Director of Eco-Cycle, a Zero Waste social enterprise based in Boulder, Colorado. Kate Bailey is International Program Developer and Senior Analyst for Eco-Cycle.