Craig Coker

Odors vary tremendously in both time and space between where they are generated and where they are perceived. Composting facilities can utilize human and field olfactometry measurement tools to better evaluate neighborhood impacts.

Odors are gaseous chemicals that are emitted into the air from a variety of sources. Some are considered pleasant, like methyl salicylate (the smell of wintergreen Altoids®) or homofuronol (the smell of baked bread). Others are less well-tolerated, like skatole (the smell of manure) or dimethyl disulfide (the smell of rotting vegetables). These gases are detectable by the human nose at various levels of concentration in the air, some of which can be detected at extremely low concentrations.

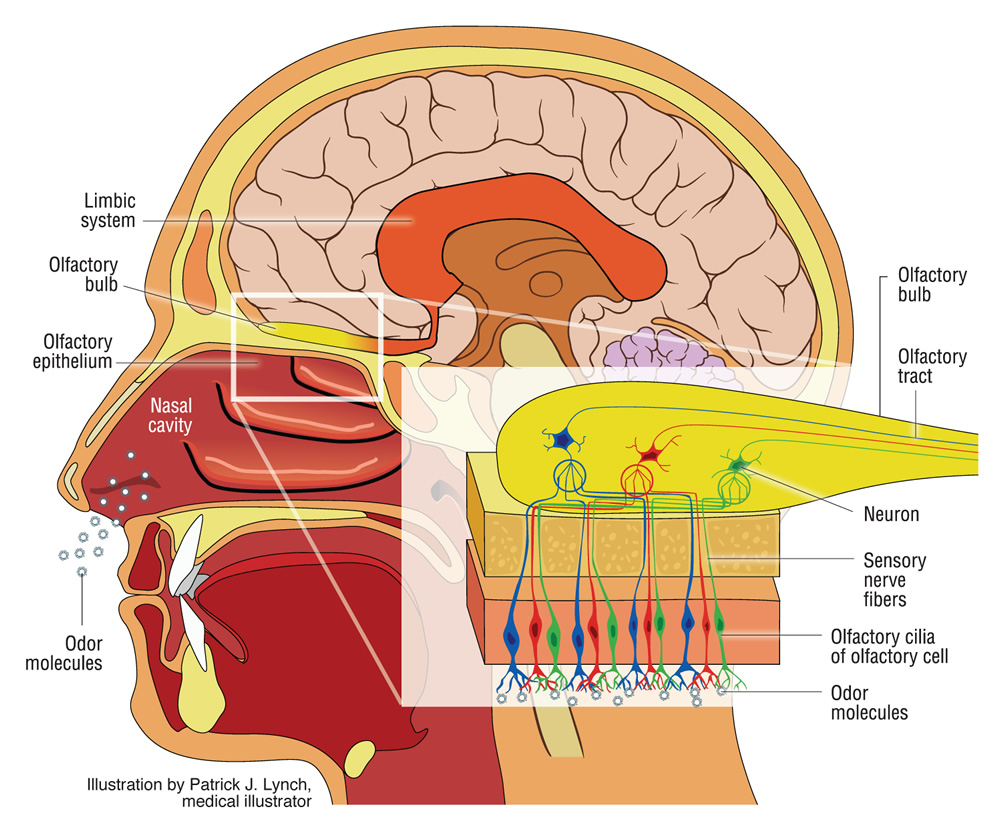

Noses of mammalian species are all similar, in that they use olfactory receptor cells in the nasal passages to detect odors. These cells have tiny hair-like cilia that contain olfactory receptors. Each receptor can bind to a limited set of odorous chemicals. Changes in calcium and sodium ions in the receptor as a result of an odor binding to a receptor sends a signal through the olfactory nerve to the olfactory bulb, where the brain interprets the electrical signal received as an odor (see illustration).

The human nose has 400 types of olfactory receptors; each is paired with a matching olfactory gene in that person’s DNA. By contrast, the human eye has only three types of receptors (blue, green, and red ranges of the color spectrum) and human taste buds have only five types of receptors (sweet, salty, bitter, sour and savory). Humans have around 900 genes that can code olfactory receptors, allowing us to detect up to 10,000 different odors; how each is perceived depends on the DNA sequencing of those 400 types of odor receptors (McRae, 2013). This is why the smell of 2-heptanone (the smell of blue cheese) is pleasing to some, and unappealing to others.

A helpful odor perception analogy is to envision the receptor nerves like strings on a guitar. As a single chemical odorant hits the olfactory receptor a single guitar string is plucked, producing a single note (for example, perceiving the rotten egg smell of hydrogen sulfide). When multiple chemical odorants are present and hit the receptors (multiple guitar strings) the result is a chord. For example, if Strings A, D and B (a C-major chord) are hit by three different odorants, the brain may perceive the earthy smell of good compost. Likewise, if Strings E, B and G (a D-major chord) are hit by three different odorants, the brain may perceive the smell of a sewer. The greater the number of odorant molecules present (higher concentrations) the louder the chord is played. The loudness of the chord is analogous to the intensity of the odor perception (St. Croix Sensory, 2005).

As discussed in earlier articles in this series, odors vary tremendously in both time and space between where they are generated and where they are perceived. Add to this that two neighbors detecting an odor will have different reactions to that odor based on the DNA coding of their odor receptors, and the difficulty of effectively monitoring odors in response to complaints becomes obvious. This article examines the topic of odor monitoring and the challenges of verifying odor complaints.

Odor Monitoring Methods

International standards are in place that dictate the scientific methods and practices of odor measurement. These standard methods for quantifying odor are: objective, quantitative, dependable and reproducible. In the U.S., the standards are ASTM E679-04: Standard Practice for Determination of Odor and Taste Threshold by a Forced-Choice Ascending Concentration Series Method of Limits and ASTM E544-99: Standard Practice for Referencing Suprathreshold Odor Intensity.

There are several means to detect odors in the ambient environment including air sampling and analysis using gas chromatography-mass spectrometry (GC-MS), human monitoring and recordation of observations using field tools like olfactometers to interpret odorous conditions, and electronic noses that use gas sensors to mimic odor receptors in the nose. Each approach has its advantages and disadvantages:

GC-MS: This method requires capturing a representative sample of air and analysis of that sample by a laboratory for its specific constituents. GC-MS is extremely useful if one is analyzing a sample for a particular chemical as it provides specific identification and quantification of molecules that form parts of the odor. This technology is used in the food and beverage industries to analyze the aromatic compounds deliberately added to foods to verify correct formulation. It is also used to detect and measure contaminants from spoilage or adulteration. The drawback to GC-MS analysis is that odors are made up of multiple chemicals, some of which act synergistically to affect perception. This method cannot measure the character of the odor, and it can be expensive (between $50 to $100/chemical/ sample).

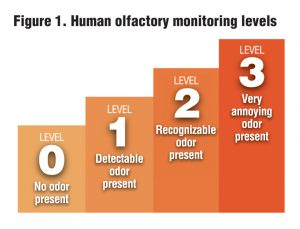

Human Olfactory Monitoring: Human olfactory monitoring was used by the compost curing facility built by the Region of Peel in Ontario, Canada several years ago. As a result of complaints, a daily odor, noise and dust monitoring protocol was established (see “Resolving Odor Challenges,” November 2012). Staff from the Region of Peel went out three times per day to monitor odor, noise and dust at 10 different stations around the facility. They were instructed to travel to each of the 10 stations and monitor outside the vehicle for several minutes, as well as drive between the stations with the vehicle windows down. They recorded odor events on a daily log sheet according to four levels (Figure 1).

Similar measurement systems were used for noise and dust. Staff was also to note any other events observed during the monitoring runs, such as wood smoke, leaf fires, manure land application, and other similar odor-producing events. If a compost curing odor was detected off-site, staff would return to the facility and investigate what work might have been underway at the facility that might have produced the odor (such as receiving of immature compost, turning windrows or screening compost).

This “human substitution” for complaints from neighbors has an advantage in that staff is monitoring for odors in the same time/space as the people detecting those odors so there is a direct correlation between neighbor and staff observations. The disadvantage of this approach is the large labor resource demand requirement for multiple monitoring observations at multiple times of day.

Olfactometry Methods: Olfactometry could be defined as the science of detecting and measuring ambient odor dilution. Olfactometry can be done in the laboratory, or in the field. Laboratory olfactometry involves diluting an odorous air sample to various concentrations then having human assessors evaluate the diluted odor to determine the detection threshold of the odor (measured as Dilutions-to-Threshold, or D/T). The laboratory dilution process simulates the dilution of the odor in the ambient air. There are specific rules and guidelines that cover who is qualified to be an odor assessor; for example, someone with chronic allergies would not be qualified. Assessors receive training in olfactory awareness, sniffing techniques, descriptor standards, and similar issues. Laboratory olfactometry is well-used by the food and fragrance industries.

Laboratory olfactometry was the basis for the Odor Monitoring Project recently conducted at the Nature’s Needs aerated static pile composting facility in North Plains, Oregon. In this project, samples of air were taken from 28 different locations within the property lines of the composting facility and these samples were evaluated using trained odor assessors. The odor samples were diluted to below odor detection limits and then introduced to a gas delivery system. A panel of eight members trained in odor response served as the odor “detector.” Panel members were asked to smell air samples delivered to one of three nose cones, one of which had the diluted sample (the other nose cones have clean air). The odor concentrations in the diluted sample were increased until one-half of the odor panel members could detect the odor, at which point the odor measurement concluded. The odor concentration was expressed as dilution-to-threshold (D/T) level, the number of dilutions that were required for one-half of the panel members to record detection. D/T levels of 1,400 to 5,400 D/T were determined from the active composting piles, but transient emissions during transfer of compost to curing were as high as 8,000 D/T.

Field olfactometry is more commonly used in the composting industry. Field work uses trained assessors to evaluate odors using one of two approaches — a standard odor intensity referencing scale (OIRS) based on n-butanol (a reference chemical) to quantify odor intensity, or field olfactometers. Most odor-related field work in composting uses field olfactometers. As in the laboratory method, field olfactometers create a series of dilutions by mixing odorous air with carbon-filtered odor-free air to produce a D/T value. The Nasal Ranger model (from St. Croix Sensory) is an example of a field olfactometer. An orifice selector dial on the hand-held unit contains six odorous air inlet openings for six different D/T values (2, 4, 7, 15, 30 and 60). The dial is replaceable for other D/T series (e.g. 60, 100, 200, 300 and 500). The assessor has to maintain a certain breathing (sniffing) rate for the device to work correctly.

The Shakopee Mdewakanton Sioux Community in Minnesota uses the Nasal Ranger field olfactometer to attempt to verify neighbors’ complaints about odors from its windrow composting facility.

Field olfactometry with the Nasal Ranger has been used by the Shakopee Mdewakanton Sioux Community (SMSC) in Minnesota to attempt to verify neighbors’ complaints about odors from its windrow composting facility. “We respond to every neighbor’s complaint as quickly as we can after a complaint is recorded, and we do daily monitoring around the site,” notes Mike Whitt, Natural Resources Manager for the SMSC. “We have a Nuisance Standard of no more than 4 D/Ts measured 15 minutes apart within a one hour period at our property line. We have accumulated over 1,400 monitoring data points since we began in July 2012, and have recorded one nuisance odor beyond our property line in 14 months of monitoring. And that event did not generate any complaints. Odors are subjective but I have learned as a scientist that one must make a best professional judgment, record the data, and move on to the next monitoring station. The data becomes more robust the longer one collects. I recognize that all complaints are real even when all the data is telling you that there is no odor present. Some people have decided that any odor at all, regardless of intensity, or whether it can be verified, is unacceptable.”

Simeon Matthews, an industrial hygienist with the Shakopee Dakota tribe, is the staffer assigned to monitor daily 14 discrete locations around the SMSC facility with the Nasal Ranger. “Learning how to inhale at the appropriate rate has been fairly easy to learn,” Matthews says, “but it’s been more of a challenge to know I’m detecting an odor at a low concentration and to assign a characteristic to that odor. Also, the odor plumes move constantly and I can’t predict or see them, so finding the point of strongest odor can take quite a while. You’re also unaware of what the odor is around you while you’re breathing filtered air, so chasing the odor can be challenging with the device over your nose.”

One challenge in collecting all this data is to develop a real-time feedback system that allows a composting operation to make modifications to its procedures. In the case of the SMSC facility, the response to a detected odor level of concern is to investigate site conditions and process controls. In one case, a pile of hay and horse manure was identified as the source; in another, fine particles had washed into the storm water forebay pond (the inlet leading into the main retention basin), which turned anaerobic and needed to be cleaned out; in a third case, they found low oxygen levels in four windrows due to inadequate free air space. While these actions were reactions to the monitoring data, the staff at the SMSC facility has learned more about the correlation between process management and odor generation and is incorporating more proactive management procedures to minimize future potential problems.

This series on odor management, available in the BioCycle archives (www.biocycle.net), has covered how and where odors are generated, measured, and perceived; how they are managed through good process control; how they are controlled with technology; how to manage the public outreach related to organics recycling odors; the basics of atmospheric dispersion; and the art and science of odor modeling.

Electronic Noses

Another technology for monitoring odors in the field is the electronic nose. These devices use arrays of sensors to mimic human olfactory senses where the human nose detects a combination of chemicals that produce an odor (the guitar chord mentioned in the analogy earlier). The types of chemically-active sensors used include: metal-oxide-semiconductors, metal-oxide-silicon field effect transistors (MOSFET), conducting polymers, surface acoustic wave devices, quartz resonators, and fiber-optic chemical sensors. Odorous molecules interact with one of these sensor arrays, changing its electrical resistance, which can be measured. The electrical data can then be analyzed using various data interpretation systems.

Electronic noses must be calibrated to the odors that need to be monitored. This is done with a three-step process: Collection of representative odor samples at the site, laboratory olfactometry to establish the odor concentration of the sample(s), and calibration of the electronic nose to the concentration in the assessed sample(s). The calibration is accomplished using a statistical nonlinear multivariable correlation technique.

These electronic noses can be used to track spatial and temporal fluctuations in odor intensities in real time. Combined with real-time odor modeling, they have the potential to give a composting facility operator a proactive approach to odor management. They can also be deployed remotely and programmed to have an active alert system based on a set point such as a limiting odor concentration at a receptor’s location.

Electronic noses are being used at the Everett/Marysville Community Odor Monitoring Project in Washington State, which is a program set up to monitor multiple sources of odors from the area where one of the Cedar Grove composting facilities is located. This project was set up in response to neighbors in the vicinity registering odor complaints with the Puget Sound Clean Air Agency, which regulates nuisance odor issues in this region.

“The agency’s contractor [Odotech, Inc.] has set up 10 electronic noses around the Everett and Marysville area to evaluate multiple sources of odors in this area,” explains Joanne Todd, Communications Supervisor for the Puget Sound Clean Air Agency. “There are four monitors owned by and at Cedar Grove, and also agency monitors at two area wastewater treatment plants, at an asphalt and concrete plant, and three ambient air monitors.” All the monitors, except the ambient air monitors, were calibrated by Odotech against air samples taken from each spot where a monitor would be installed so that the monitors would record the presence of one of these calibrated odors each time it was detected.

Todd notes that data collection is still going on, so it is too soon to draw any conclusions. One aspect of the odor monitoring program that is working well is the use of citizen odor monitors. “We have 11 citizen odor monitors, all of whom underwent specific odor monitoring training,” she adds. “They were all volunteers who are very interested in the odor situation in this area and are working hard to make the most conscientious choices they can. We feel it is very important to involve area citizens in this type of evaluation; after all, they know better than we do what they smell every day. One benefit of this study that we have noticed is there is a lot less skepticism about where odors are coming from than there was before we started, in that they now understand that there are multiple sources of odors in a community.”

It is a challenge to monitor an environmental phenomenon like odor that changes in time, in space and in the noses of the people affected by the odor. Good technologies are available that can be deployed, and when coupled with properly trained monitors, they offer potential for more objective assessments and real-time solutions to these often-difficult issues.

Craig Coker is a Contributing Editor to BioCycle and a Principal in the firm Coker Composting & Consulting (www.cokercompost.com), near Roanoke VA. He can be reached at cscoker@verizon.net.