Top: Vanguard Renewables’ codigestion facility, which receives slurried and liquid food waste and produces RNG, is located on the Goodrich Family Farm, a 900-head dairy in Salisbury, Vermont. Photo courtesy of Vanguard Renewables.

Brad Pleima

Brad Pleima

The U.S. Environmental Protection Agency’s (USEPA) Renewable Fuel Standard (RFS) 2023-2025 Set Rule, released in June 2023, introduced significant opportunities for the renewable natural gas (RNG) and biogas industries. Included in the rule were provisions specific to RNG, referred to as the Biogas Regulatory Reform Rule (BRRR). By allowing the codigestion of feedstocks to generate both D3 and D5 Renewable Identification Numbers (RINs), the rule offers a path to enhanced revenue streams for RNG projects. However, capitalizing on these opportunities requires strategic planning and operational readiness.

IBC totes of beverage waste arriving at Reinford Farms in Mifflintown, Pennsylvania. Photo by Nora Goldstein

A Shift in RIN Calculations

Codigestion refers to the process in which multiple organic feedstocks, such as dairy manure (classified as a D3 feedstock under the RFS) and food waste (classified as a D5 feedstock), are processed together in a single anaerobic digester (AD) to produce biogas. Previously, facilities codigesting non-cellulosic material faced limitations — RNG derived from codigested D3 and D5-eligible feedstocks would default to the lower D5 RIN category.

Codigestion refers to the process in which multiple organic feedstocks, such as dairy manure (classified as a D3 feedstock under the RFS) and food waste (classified as a D5 feedstock), are processed together in a single anaerobic digester (AD) to produce biogas. Previously, facilities codigesting non-cellulosic material faced limitations — RNG derived from codigested D3 and D5-eligible feedstocks would default to the lower D5 RIN category.

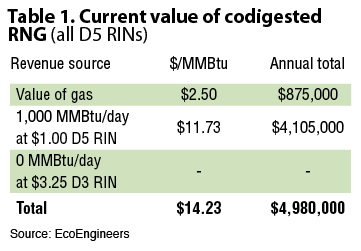

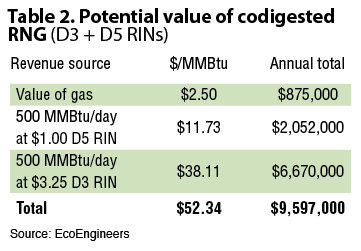

The RFS Set Rule, however, allows for allocating D3 and D5 RINs based on the cellulosic converted fraction (CCF), a calculated measure of the amount of biogas produced from a D3-eligible feedstock. This fraction is critical, as it determines how much of the generated gas can be attributed to each feedstock type, thereby unlocking the potential for higher revenue streams through higher value D3 RIN generation. Tables 1 and 2 illustrate the revenue benefits gained from utilizing the RFS Set Rule for codigestion projects.

The RFS Set Rule, however, allows for allocating D3 and D5 RINs based on the cellulosic converted fraction (CCF), a calculated measure of the amount of biogas produced from a D3-eligible feedstock. This fraction is critical, as it determines how much of the generated gas can be attributed to each feedstock type, thereby unlocking the potential for higher revenue streams through higher value D3 RIN generation. Tables 1 and 2 illustrate the revenue benefits gained from utilizing the RFS Set Rule for codigestion projects.

The RFS Set Rule allows two methods for calculating the D3-D5 split: a literature-based approach and a site-specific method:

- Literature-Based Approach: This method uses conservative biogas conversion estimates provided by the USEPA. It relies on predetermined values for the CCF of various feedstocks, such as swine manure, bovine manure, chicken manure, and municipal wastewater treatment biosolids. These values are linked to specific operational conditions, such as a minimum temperature of 95°F and hydraulic and solids retention time exceeding 20 days.

- Site-Specific Method: This approach allows facilities to establish a custom conversion factor based on historical data and precise measurements of the digester’s operating conditions, including temperature, pressure, and residence time. The resulting CCF is applicable only if the digester operates within these measured parameters.

For facilities with established baselines, the site-specific method can retain up to 90% to 100% of the D3 RIN value, offering a significant advantage over the conservative literature approach, which may only capture 50% of the D3 RIN value.

The food waste slurry generated at the depackaging facility in the City of Sunnyvale, California, is codigested with biosolids at wastewater treatment plants in the region. Photo courtesy of Van Dyk Recycling Solutions

At this time, there is not a detailed methodology for how to comply with USEPA’s new split methodologies, especially on the facility-specific path. The exact compliance requirements are not known and the industry will learn more as USEPA considers more of these pathways. EcoEngineers, a consulting, auditing, and advisory firm experienced in the biogas RNG space, expects that facilities participating in the USEPA’s RFS Quality Assurance Program (QAP) will have site-specific protocols approved by USEPA to detail future compliance requirements. Established in 2014, the QAP provides a means for ensuring that RINs are properly generated through audits of renewable fuel production conducted by independent third parties. It is a voluntary audit program, but participation is required for AD facilities to get the full value out of a D3 or D5 RIN.

Implementation Considerations

Transitioning to codigestion requires a thorough assessment of biogas and RNG facility capabilities and economic feasibility. Facilities must evaluate their digesters to determine if they can handle diverse feedstocks without compromising efficiency. Essential components include blending tanks for material preparation, adequate mixing systems to maintain digester performance, measurement devices for tracking each feedstock, solids separation or storage infrastructure, and RNG upgrading infrastructure to process the additional biogas generated.

Additionally, digestate management becomes more complex when non-cellulosic materials are introduced. Facilities must account for changes in volume and composition, which could impact disposal methods. For example, dairy farms accustomed to land-applying manure may find new challenges when dealing with a food waste-derived digestate.

A hydrolyzer tank equipped with top-mounted mixers at Goodrich Family Farm in Salisbury, Vermont is an example of an essential feedstock conditioning component when codigesting food waste with manure. Photo courtesy of Vanguard Renewables

Steps for Codigestion Success

- Evaluate and Secure Feedstock: Access to consistent and appropriate feedstocks is the first critical step. Without a reliable feedstock supply, projects cannot proceed. For example, a dairy farm might want to partner with local food processing plants to secure a steady supply of food waste, ensuring a continuous feedstock stream for codigestion. Determining potential codigestion feedstocks and biogas potential is a key first step. Importantly, the feedstocks must meet the regulatory definition of “renewable biomass” under the RFS to qualify for D5 RINs. While not all feedstocks are considered equal, “food waste” generally takes a broad meaning under the RFS.

- Assess Facility Readiness: Conduct a feasibility analysis to evaluate infrastructure, including blending and digestate management systems, and determine whether upgrades are needed. For instance, a wastewater treatment plant (WWTP) might need to install additional blending tanks and mixing systems to handle the increased volume and diversity of feedstocks.

- Evaluate Revenue Potential: Analyze the economic benefits of codigestion. This involves calculating potential increases in biogas production and revenue from RINs or voluntary markets.

- Navigate USEPA Approval: Facilities must obtain USEPA approval for their chosen RIN calculation methodology. While the process is outlined in the regulation, no projects have completed this pathway yet, although several are underway, making it essential to work with experts to navigate uncharted territory. To ensure compliance with the RFS program, facilities must also complete a RFS Engineering Review to obtain a revised RFS pathway. They may also want to consider participating in the USEPA’s QAP to verify that the RINs they are generating are valid.

- Monitor Market Opportunities: Beyond D3 and D5 RINs, facilities can explore voluntary markets where biogas from codigestion can often command a higher value. For instance, a producer might consider selling its RNG to companies looking to offset their carbon footprint, thereby accessing premium prices in the voluntary carbon market compared to generating lower value D5 RINs.

Who Benefits?

One of the primary economic benefits of codigestion is the increased energy production potential. By adding energy-rich organic waste materials such as fats, oils, and grease (FOG) and food scraps to dairy or wastewater treatment plant digesters, facilities can boost biogas production. Many of these high energy materials can have three to five times the methane production potential of biosolids and manure, leading to higher biogas yields and, consequently, more revenue. Additionally, codigestion can provide economic benefits through potential revenue from tipping fees for accepting food waste.

The use of existing infrastructure for codigestion also contributes to cost savings. Facilities that already have ADs can utilize their excess capacity to process additional feedstocks without the need for significant capital investment in new equipment. This makes codigestion a cost-effective solution for enhancing biogas production and revenue generation and provides a home for problematic feedstocks such as FOG, which clog public sewer lines.

Long-Term Outlook

While the immediate road to implementation may be challenging, the long-term future of RNG and biogas looks promising. In the short term, the biogas industry will need to stay vigilant and proactive in addressing potential regulatory and policy shifts that could impact their business. The industry is navigating a transitional phase due to changing regulations and new markets as biogas/RNG becomes more mainstream. But the 10-to-20-year outlook suggests a smoother path ahead as advancements in technology unlock new potential.

Emerging technologies such as carbon capture and storage (CCS) and smart grids/solar integration are expected to enhance the efficiency and sustainability of biogas projects. This can lead to a lower carbon intensity score, increased production, and lower cost of delivery, among other benefits. The USEPA’s RFS Set Rule is also a step in the right direction for maximizing the value of biogas, whether used for RNG, renewable electricity, low-carbon hydrogen, or sustainable aviation fuel (SAF).

A Call to Action

For biogas and RNG operators, the message is clear: analyze your options. By conducting a thorough feasibility study and assessing operational readiness, you can determine whether codigestion aligns with your goals. Collaborating with industry experts and stakeholders can provide valuable insights into the risks and rewards of this opportunity, ensuring that you have the data to make informed decisions.

For example, the American Biogas Council (ABC) provides resources to help project developers and operators navigate the complexities of biogas production and utilization. Additionally, collaborating with regulatory consultants and leveraging tools like the Biogas Carbon Accounting Tool (CAT) can help facilities optimize their carbon accounting practices and maximize the benefits of their biogas projects.

With the USEPA’s RFS Set Rule in effect, it is timely to maximize the benefits of feedstock codigestion to monetize the full potential of both D5 and D3 RIN values. By taking proactive steps, biogas and RNG facilities can position themselves to capture additional revenue and contribute to a more sustainable energy future.

Brad Pleima is the President of EcoEngineers, a consulting, auditing, and advisory firm recently acquired by leading global assurance partner LRQA. He has more than 20 years of experience in the renewable energy and engineering sectors, working with municipalities, project developers, and investors on anaerobic digestion, biogas utilization assessments, and biogas upgrading projects, and advising clients on global climate regulations, emerging incentive programs, new technologies, evolving carbon markets, data standards, energy credit markets, commodity markets, feedstocks, and carbon accounting rules.