Energy efficient digester mixers and treatment plant blowers, as well as installation of a solar array, FOG receiving system and two 400 kW CHP engines, are credited with helping to achieve energy net zero performance.

Nora Goldstein

BioCycle March/April 2015

The City of Gresham, Oregon’s wastewater treatment plant, located near the Columbia River, is a basic secondary activated sludge facility with 20 million gallons/day (mgd) of capacity. Average flows are around 13 mgd. Class B biosolids produced at the plant are applied to agricultural fields.

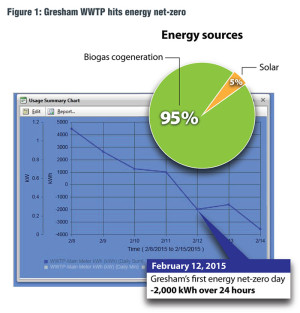

While on the surface that seems pretty run of the mill for wastewater treatment, the City of Gresham’s WWTP is anything but. “We had our first energy net zero day on 2/12,” emailed Alan Johnston, Senior Engineer with the City of Gresham. “My presentation at the BioCycle West Coast Conference will be the first time I can present actual net zero production data instead of discussing the possibility of a future energy net zero day.”

The city’s journey to energy net zero began when the plant installed anaerobic digesters around 1990. Biogas was fed, without any treatment, to a 250 kW generator. “In the early 2000s, we started seeing serious combustion problems with the engine, caused in part by the siloxanes in the wastewater,” recalls Johnston. “We began evaluating options, and in 2005, installed a 400 kW combined heat and power (CHP) CAT engine and biogas treatment system to remove moisture, hydrogen sulfide and siloxanes.” The CHP engine produces power and heats the buildings with jacket water heat. It has been supplying 50 percent of the treatment plant’s power needs since 2005, or about $250,000 in annual avoided electrical costs.

The City of Gresham received a grant of $82,000 from the Energy Trust of Oregon and a $288,000 grant from the Oregon Department of Energy for the $1.13 million CHP unit. The Energy Trust, based in Portland, is an independent nonprofit organization established in 2002 to help utility customers benefit from saving energy and generating renewable power (see sidebar). Funds for its investments and technical assistance come from ratepayers of Portland General Electric, Pacific Power, NW Natural and Cascade Natural Gas.

Energy Efficiency, FOG Analyses

Even with the 400 kW cogeneration unit, biogas had to be flared, notes Johnson. “It was not another 400 kW worth, and we looked at putting in a larger 600 kW CHP unit. But after some analysis, it was decided to shift our focus in 2008 and 2009 to both power consumption reduction projects and increasing biogas production. The City received a grant from the Energy Trust to evaluate energy efficiency options as well as how to go further along the path to energy net zero.”

The 2008 study, conducted by Kennedy Jenks and the Oregon Association of Clean Water Agencies (ACWA), identified the potential to become Energy Net-Zero by first concentrating on energy efficiency measures and then investigating a Fats, Oils and Grease (FOG) receiving program.

In 2010, energy efficiency measures were constructed that included replacing the digester mixing equipment installed in 1990 — a biogas mixing system with three 40 hp compressors — with two linear motion mixers (1/digester) that consume 5 hp/unit. In addition, the city replaced two multistage blowers that supply air to the aeration basins with two turbo blowers. Fine bubble diffusers were also installed in all the aeration basins. “Those steps dropped power consumption from about 6.2 million kWh/year to 5.2 million kWh/year,” says Johnston. “The turbo blowers were a big part of that 17 percent reduction.”

Following the energy efficiency measures, the City of Gresham began looking at additional ways to become energy net zero. In December 2009, a 420 kW peak capacity ground-mounted solar energy system was installed at no capital cost to the city (funding came from the Energy Trust and the state). A power purchase agreement was signed with Sun Edison, and the city signed a net metering agreement with Portland General Electric, essentially buying back the power it produces for use at the WWTP.

Per the recommendation in the 2008 study to investigate codigestion to increase biogas production, the city received a $40,000 grant in 2009 from the Oregon Economic Development Department to evaluate the feasibility of installing a grease/food waste injection system. “That study, conducted by CH2M Hill, set the path for where we are now,” he adds. “The findings showed that adding FOG receiving facilities is economically viable and that there is a market for this service in our area.”

Haulers connect to the FOG receiving station, comprised of two tanks, a FOG grinder, unload/tank mixing pump and a feed pump. Tipping fee is $.08/gallon. The plant has two 400 kW CAT engines (right).

The study indicated that a FOG tipping fee would be required, and that the WWTP would need 7,000 to 11,000 gallons/day of FOG. The estimated cost of the FOG receiving and injection system was $3.7 million. In 2012, a 10,000-gallon FOG receiving tank was installed, along with a FOG grinder, unload/tank mixing pump and a feed pump. A second tank (20,000 gallon capacity) and receiving station were added in April 2014. In addition to FOG, food processing residuals are received. A total of $500,000 in tipping fee revenues were collected in 2013 and 2014.

To solicit haulers, the city ran an advertisement, and contracts were eventually signed with three haulers. The tipping fee is 8 cents/gallon. A card key system was installed for tracking and billing, therefore a WWTP employee does not need to be available when a tanker truck arrives to unload. “The haulers connect to the FOG receiving station, and empty their trucks,” explains Johnston. “The material is ground and screened before going into the holding tanks. Contents of the tanks are heated to 100°F to keep them from solidifying. A programmable logic controller (PLC) controls injection into the digester, feeding at the most constant rate possible over a 24-hour period. This avoids loading slugs of high strength organics into the digesters. The PLC also manages the levels in each tank, ensuring the contents are transferred as needed.”

Installation of the FOG receiving system coincided with a change in the Oregon plumbing code (December 2012) that mandated food service establishments install grease interceptors. In addition, the city has had a FOG pretreatment specialist on staff for a number of years, whose responsibilities include ensuring that grease interceptors and grease traps are cleaned.

Overall, addition of FOG and food processing residuals to the Gresham WWTP digesters has dramatically increased biogas production. Prior to installation of the high strength organics receiving system, biogas production averaged 180,000 standard cubic feet (scf)/day. Once the system came on line, biogas production has ranged from about 250,000 scf/day to a high of almost 400,000 scf/day. “Our goal is to average 280,000 to 300,000 scf/day,” notes Johnston. “This amount of biogas will continually operate both our original and the new 400 kW cogenerators [CHPs].”

A 420 kW peak capacity ground-mounted solar energy system was installed in late 2009 at no capital cost to the City of Gresham.

Achieving Net Zero

Over this 10-year journey to energy net zero, the Energy Trust of Oregon has supported the City of Gresham with technical assistance, project development support, and cash incentives that lowered the costs of the energy efficiency measures as well as the two CHP engines and the solar electric system. Business Energy Tax credits and biomass incentive funds from the State of Oregon also were essential to making net zero a reality.

The second 400 kW CHP unit came on line in January 2015. And on February 12, the Gresham WWTP had its first energy net zero day (Figure 1). “It’s hard to say if we will achieve net zero for a full year, but since February 12, we have produced more power than we have used,” he adds. “There are a lot of technical issues that impact net zero performance. For example, staff will need to take the engines off line during digester cleanings and cooling the engines with treated effluent relies on other pumping systems in the plant being reliable. Our ultimate goal is to be energy net zero annually.”

Johnston, who anticipates about $500,000/year in avoided electric utility expenses, is fairly certain that the City of Gresham WWTP is the first medium-size wastewater treatment plant to be net zero using sustainable biogas cogeneration, and one of a handful of any size in the U.S. that has achieved net zero. “Getting to energy net zero has been an interesting journey,” he notes. “Most people in the wastewater treatment industry are familiar with the energy efficiency and energy generation concepts. It’s pulling the trigger that makes the difference. Operators need to study their plants and determine what is feasible. In our case, we got lucky with a little extra capacity in our digesters and were able to move things around in our digester building to fit the second CHP unit without constructing additional buildings. We also are lucky that we have operators who have welcomed the idea of operating a complex cogeneration and FOG receiving system.”