Top: Clean Water Services tested agricultural soils for PFAS compounds where biosolids had been land applied. Photo courtesy Scott Mansell

Sally Brown and Scott Mansell

Sally Brown and Scott Mansell

“Why all the fuss?” is the question that goes both ways when it comes to PFAS in biosolids. From one perspective, the fact that you can detect PFAS in biosolids appears to be reason enough to burn or landfill the stuff. From another perspective, there is a relatively simple and cost-effective way to reduce industrial PFAS inputs into our wastewater. Once you take away the industrial sources, the primary sources are our homes, offices, fine and fast dining establishments, and other commercial sources. It turns out that you can have your cake and eat it, too. As I’m referring to biosolids cake you might not be tempted to actually eat the stuff. In fact, I would advise strongly against it. However, feed it to your soil and it will thank you and thank you some more.

My crop of onions, grown in Class A biosolids, is just one example of the truth in that statement. So are many examples in the peer-reviewed literature (Cogger et al., 2013; Una et al., 2022). That is why biosolids are a stupid thing to waste. Adding biosolids to soils instead of putting them in landfills is a tried and true way to maintain soil productivity and improve soil health. This is something that we’ve known since the use of night soil. Treatment has taken the pathogens away, and pretreatment can reduce the PFAS. Keeping biosolids out of landfills not only enriches the soils, it helps clear the air. Each dry ton of biosolids you put in a landfill emits about 3 tons of carbon dioxide (CO2).

If you’ve been following this series, you are all too aware of the fact that biosolids contain PFAS. While some would suggest that is reason enough to toss or burn the stuff, there is a simple approach that will keep your soil well fed and also reduce the PFAS concentrations in the biosolids. This became clear at our annual Northwest Biosolids conference. Scott Mansell, this column’s coauthor, is an engineer with Clean Water Services (CWS). He reported on the utility’s efforts to get a handle on PFAS in the biosolids that it manages. CWS is a sewer and stormwater utility that serves over half a million people just west of Portland, Oregon. They operate four water resource recovery facilities (WRRFs) that range in size from small (approximately 6 million gallons per day or MGD) to not quite as small (approximately 46 MGD), and land apply the Class B biosolids from those WRRFs.

Source Control

As with the majority of utilities, CWS has a source control division. Source control is one of the terms used for the staff that monitors the quality of the water (influent) coming into each of the WRRFs. Their job includes regulating industrial discharges to the sanitary and storm water conveyance system for pollutants and gases that might be a concern to the environment, public health, or treatment operations. Regulated metals are an obvious one here. Biological oxygen demand and nitrates are another. CWS added PFAS to that list.

Rather than cowering in the face of upcoming regulations and public scrutiny (and the New York Times), CWA opted to go on the offensive using a five-point approach:

- Understand occurrence, risk, and treatment options at the WRRFs

- Identify, quantify, and address sources in the sewershed and watershed

- Understand fate and implications of PFAS in WRRF effluent, recycled water, and biosolids

- Prepare for future regulations, help provide datasets for regulators and others, and build partnerships

- Develop the ability to measure PFAS and other compounds at CWS’ in-house lab

Since 2019, CWS has collected and analyzed over 1,100 samples for PFAS. And those samples tell a story. The utility’s service area includes many large industries. While domestic flow (your flushes) and commercial discharges (dishwashing at the Denny’s) are not subject to federal pretreatment requirements, the industries can be. Local utilities may have the ability to regulate commercial users as well. Pretreatment means that before a facility can discharge industrial wastewater into a municipal sanitary sewer system, it must be treated to remove regulated contaminants.

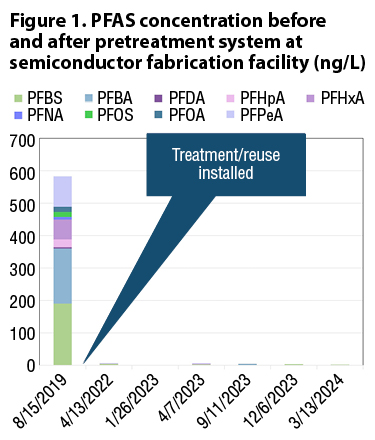

For example, pretreatment was used in the olden days to reduce cadmium (regulated under the EPA Part 503 regulations) discharges into the Chicago system. This resulted in a huge decrease in the cadmium in the city’s biosolids from over 400 ppm to less than 4 ppm. The regulatory limit is 39 ppm. Pretreatment also works for PFAS. In 2019, CWS identified a large semiconductor fabrication facility as a major source of PFAS into its sanitary system. CWS worked with industry to implement a PFAS Management Plan. With CWS’ strong relationship and detailed discussions with the facility, the company opted to upgrade its treatment system to one that could remove PFAS. As expected, the PFAS in its discharges went away (Figure 1). The reduced PFAS concentrations in discharges from the factory resulted in decreased mass of PFAS entering the WRRF.

For example, pretreatment was used in the olden days to reduce cadmium (regulated under the EPA Part 503 regulations) discharges into the Chicago system. This resulted in a huge decrease in the cadmium in the city’s biosolids from over 400 ppm to less than 4 ppm. The regulatory limit is 39 ppm. Pretreatment also works for PFAS. In 2019, CWS identified a large semiconductor fabrication facility as a major source of PFAS into its sanitary system. CWS worked with industry to implement a PFAS Management Plan. With CWS’ strong relationship and detailed discussions with the facility, the company opted to upgrade its treatment system to one that could remove PFAS. As expected, the PFAS in its discharges went away (Figure 1). The reduced PFAS concentrations in discharges from the factory resulted in decreased mass of PFAS entering the WRRF.

In another case, CWS tracked a large source of elevated PFOA through its collection system to a specific source. As soon as CWS initiated outreach to the facility and began sampling within the facility’s campus, there was a very large decrease in PFOA concentrations in the influent entering the WRRF. In short, the problem went away. CWS has now worked with all of the regulated industries in its sewersheds to develop PFAS Management Plans and will have them all in place within another year.

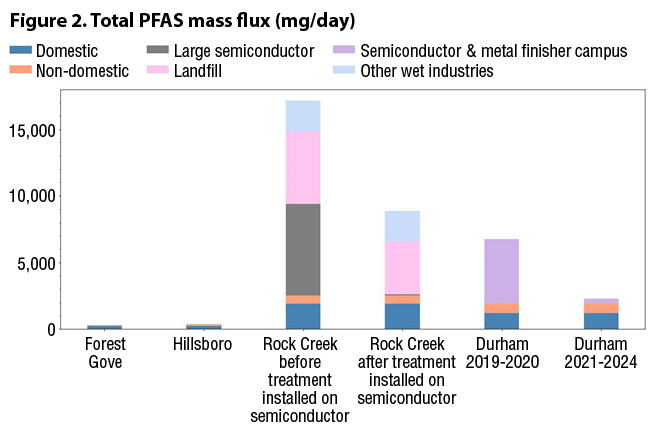

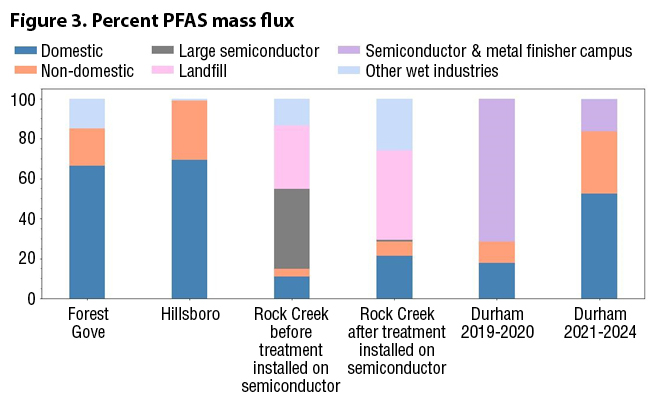

With its detective work and sampling, CWS has been able to identify the major sources of PFAS in the sewer system by concentration (Figure 2) and percent (Figure 3). Leachate from the local landfill, along with a few individual industries, were the main sources of PFAS from the industrial sectors. Monitoring shows that some industries, such as metal finishers and rubber manufacturers, can have relatively high concentrations of PFAS in their discharges, but the relative size of the flows from these industries largely determines their impact.

Tackling Domestic And Commercial Sources

Elevated PFAS concentrations at the WRRFs were associated with larger industrial inputs. As long as the industrial sources in a sewershed are controlled, you can expect low concentrations of PFAS in biosolids. However, PFAS also comes from homes and businesses. With the exception of one facility where landfill leachate is still the largest source, the domestic and commercial sectors are now the largest source of PFAS to each of the WRRFs. These results tell you that identifying industrial sources and working with them to help reduce PFAS in their discharges is highly effective at reducing PFAS into WRRFs. It is effective even if regulators outside of the water sector don’t have the nerve to ban most uses of these chemicals.

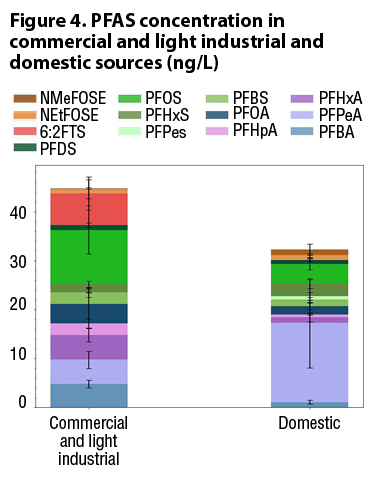

As a result, industrial source control won’t get us all the way to low or no PFAS in biosolids. Because most of the PFAS mass in biosolids is coming from domestic and commercial sources, getting them out of consumer products is the only long-term answer (Figure 4). Ironically, the fact that most of the PFAS in biosolids are coming from domestic and commercial sectors means that by attempting to avoid exposure of people to PFAS by limiting land application of biosolids, you’re trying to limit their exposure to what they’ve already been exposed to. That’s like trying to keep somebody away from secondhand smoke while ignoring that they are chain smoking cigarettes.

As a result, industrial source control won’t get us all the way to low or no PFAS in biosolids. Because most of the PFAS mass in biosolids is coming from domestic and commercial sources, getting them out of consumer products is the only long-term answer (Figure 4). Ironically, the fact that most of the PFAS in biosolids are coming from domestic and commercial sectors means that by attempting to avoid exposure of people to PFAS by limiting land application of biosolids, you’re trying to limit their exposure to what they’ve already been exposed to. That’s like trying to keep somebody away from secondhand smoke while ignoring that they are chain smoking cigarettes.

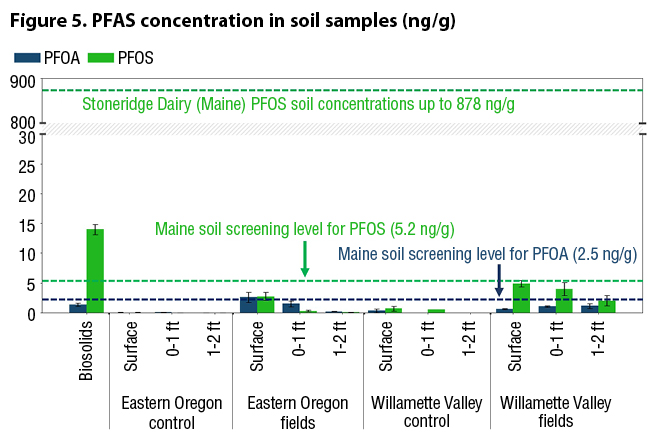

CWS also tested soils where its biosolids have been applied. These included soils in Eastern Oregon where dryland wheat is grown and in Western Oregon where the soils are used to grow grass seed. For both areas, biosolids have been used anywhere from 5 to 11 years. Soil samples were collected at the surface, from zero feet to one foot and from one foot to two feet. For all fields, the PFOA and PFOS concentrations were below the soil screening level used in Maine (2.5 ng/g and 5.2 ngg, respectively) even when the biosolids were from WRRFs where industries were the largest source of PFAS. As a point of comparison (Figure 5), one of the dairies in Maine often cited in the media where milk was found to be high in PFAS had soil PFOS concentrations as high as 878 ng/g (Maine Dept of Health and Human Services, 2020).

The U.S. EPA will soon issue draft guidance on these compounds in biosolids. I really hope that common sense can prevail. Pretreatment is a classic case of the KISS (keep it simple, stupid) principle. It is simple, cost-effective and it works. PFAS are the problem, not the biosolids. There are many reasons not to throw the baby out with the bathwater, not the least of which is clogging the grit screens at the WRRF.

Sally Brown, BioCycle Senior Adviser, is a Research Professor at the University of Washington in the College of the Environment. Scott Mansell is a principal engineer in the Research and Innovation Program at Clean Water Services in Hillsboro, Oregon.