2020 PFAS Update Series, Part II

Requirements in Minnesota for treatment of composting site “contact water” that contains PFAS prompted analysis of available technologies.

Part II

Craig Coker

Per- and polyfluoroalkyl substances (PFAS) are a large group of compounds used in nonstick coatings, textiles, paper products, some firefighting foams, and many other products. Some of the perfluoroalkyl acids, such as perfluorooctanoic acid (PFOA) and perfluorooctane sulfonate (PFOS), are mobile, persistent, and bioaccumulative. Both PFOA and PFOS are known to bioaccumulate in the body of people of all ages, even before birth. Once ingested or inhaled, PFOA and PFOS accumulate in the blood serum for extended periods of time, as PFOA and PFOS have half-lives of 2.3 years and 8 years, respectively (NRDC, 2018). Both chemicals are proven carcinogens.

Preliminary data from a September 2019 study conducted at Minnesota composting sites (Driver, 2019) reveals PFAS was detected in “contact water” at both yard trimmings and source separated organic matter (SSOM) composting facilities at actionable levels ranging from 0.06 to 3.4 micrograms per liter (µg/L), which is 60 to 3,400 parts per trillion (ppt). In Minnesota, “contact water” is any rainfall-induced runoff or leachate coming from any compost which has not achieved a Solvita maturity index greater than or equal to five with an ammonia test result of greater than or equal to four.

These detected PFAS levels are above U.S. EPA’s 70 ppt drinking water health advisory (HA) level, above the Minnesota Pollution Control Agency (MPCA) intervention limits for PFAS in groundwater (0.075 µg/L or 75 ppt for PFOS and 0.00875 µg/L or 8.75 ppt for PFOA), and above the Health Risk Levels/Health-Based Values (HRL/HBV) set by Minnesota Department of Health in 2019 for contaminants in groundwater, which are 0.015 µg/L or 15 ppt for PFOS and 0.035 µg/L or 35 ppt for PFOA. Following MPCA Solid Waste Program guidance, contact water must meet a quarter of the HRL or HBV value for a specific analyte, defined as the Intervention Limit (ILs). The IL is a level that shows when additional action must be taken.

A composting site in New York that processed paper mill residuals and yard and leaf feedstocks for many years came under New York State Department of Environmental Conservation (NYDEC) scrutiny in 2017, with PFOA and PFOS being found in paper mill sludge, finished compost material, and water flowing from the compost to the collection pond. It also was detected in the facility’s groundwater monitoring well and storm water collection pond at levels that, we have learned since, are fairly typical. Surface and monitoring well waters have PFOA and PFOS above the EPA drinking water HA, but not at the very high levels associated with firefighting and manufacturing sites (NYDEC, 2017).

The Minnesota and New York test results are likely to be repeatable in other states, which may someday lead to further constraints on discharging storm water to receiving waters without treatment or requiring full capture and reuse of contact water/leachate as moisture additive in the composting process. However, reusing this water in the composting process risks cycling the PFAS chemicals back into the compost.

Treatment Technologies

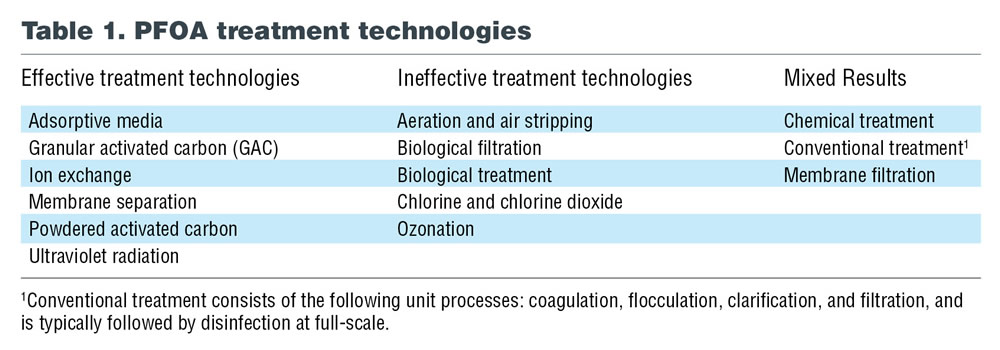

Treating contact water/leachate or groundwater to remove PFAS chemicals is possible. EPA has assembled the Drinking Water Treatability Database, which can be used to identify effective drinking water treatment processes. Table 1 is a summary of the technologies identified for treating PFOA.

The following processes were found to be effective for the removal of PFOS: GAC (up to >99% removal in bench tests), high-pressure membranes such as nanofiltration and reverse osmosis (up to > 99% removal), ion exchange (up to >99% removal), and powdered activated carbon (up to 99% removal). Part I of our series on “PFAS In Composting and Anaerobic Digestion” reports on GAC treatment. Part III covers membrane and ion exchange treatment technologies.

The following processes were found to be effective for the removal of PFOS: GAC (up to >99% removal in bench tests), high-pressure membranes such as nanofiltration and reverse osmosis (up to > 99% removal), ion exchange (up to >99% removal), and powdered activated carbon (up to 99% removal). Part I of our series on “PFAS In Composting and Anaerobic Digestion” reports on GAC treatment. Part III covers membrane and ion exchange treatment technologies.

Granular Activated Carbon

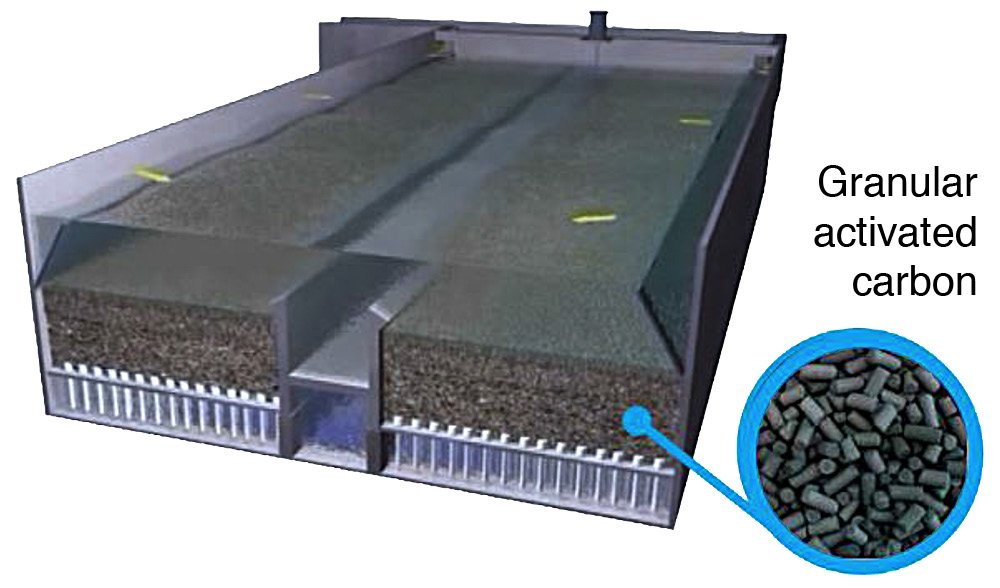

Activated carbon treatment is the most studied treatment for PFAS removal. Activated carbon is an effective adsorbent because it is a highly porous material and supplies a large surface area to which contaminants may adsorb. Activated carbon is made from organic materials with high carbon contents such as wood, lignite, and coal. It is often used in granular form called granular activated carbon. GAC is a hybrid mixture of a wide variety of graphite platelets that are interconnected by nongraphitic carbon bonding.

The adsorptive capacity of GAC makes it ideal for removing a variety of contaminants from water, air, liquids and gases. Adsorption results from the interaction of the electronic structure of an adsorbent, such as activated carbon, with an adsorbate, such as PFOA or PFOS (think how tape sticks to what it is applied to). GAC removal efficiencies for a suite of 23 PFAS chemicals was determined to exceed 90% for 20 PFAS chemicals, between 10% and 90% for two, and less than 10% for one (Dickenson, 2016).

Figure 1. GAC treatment system

Image courtesy of Suez Water Technologies

Figure 1 is an illustration of a GAC system. Primary factors in determining the required GAC contactor volume are: 1) Breakthrough; 2) Empty bed contact time (EBCT); and 3) Design flow rate. Breakthrough is the time when the concentration of a contaminant in the effluent of the GAC unit exceeds the treatment requirement. As a rule of thumb, if the GAC effluent concentration is greater than the performance standard for over three consecutive days, the GAC is exhausted and must be replaced/regenerated.

The EBCT is calculated as the empty bed volume divided by the flowrate through the carbon. Longer EBCTs can be achieved by increasing the bed volume or reducing the flow rate through the filter. The EBCT and the design flow rate define the amount of carbon to be contained in the adsorption units. A longer EBCT can delay breakthrough and reduce the GAC replacement/regeneration frequency. The carbon depth and adsorber volume can be determined once the optimum EBCT is established. Typical EBCTs for water treatment applications range between 5 to 25 minutes (EPA, 2020).

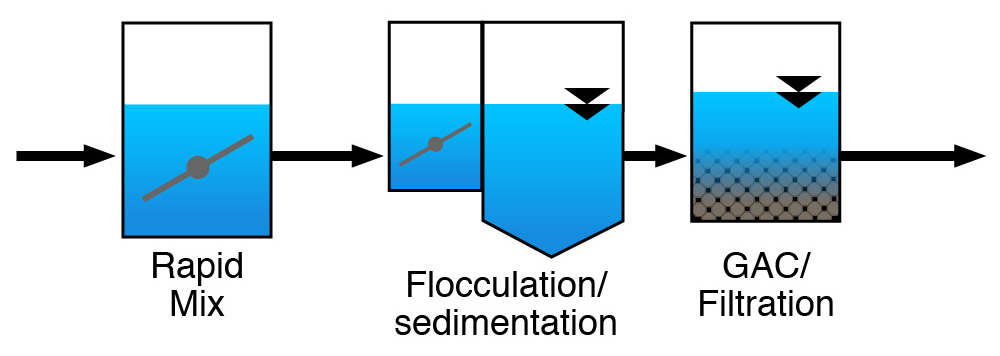

Figure 2. Flocculation of fine particles with a polymer followed by a quiescent settling chamber or tank

As composting facility contact water and storm water runoff usually have high concentrations of total suspended solids, some pretreatment is recommended before the water enters the GAC unit. Flocculation of fine particles with a polymer followed by a quiescent settling chamber or tank is recommended as shown in Figure 2.

Calgon Corporation, a maker of GAC, recently reported on PFAS removal using its Filtrasorb GAC product, which is made from bituminous coal (Ryan, 2018). A solution containing 200 ppt of multiple PFAS chemicals was made and run through the contactor with a 10-minute EBCT. Researchers measured breakthrough of PFOA at the EPA HA level of 70 ppt after 790 days and measured no breakthrough of PFOS when the test was halted at 1,095 days (3 years). They estimated a treatment cost of $0.14/1,000 gallons. They also reported on the results of reactivating the carbon at 1,800°F, showing PFOA and PFOS levels below 1 ppt in the reactivated carbon.

Craig Coker is a Senior Editor at BioCycle and CEO of Coker Composting & Consulting near Roanoke, VA. He can be reached at ccoker@jgpress.com.