Top: Understanding your feedstocks also requires understanding their characteristics. Photo by Doug Pinkerton

Jorge Montezuma

Composting is an art and a science and necessarily involves trial and error, especially in the beginning. It is an iterative process of tweaking variables until you find what works well for your operation. A key variable that must be determined is the composting mixture recipe. One way to shorten the trial-and-error time involved in finding the right mix is to begin with an ideal starting composting recipe, which can save you months of experimentation. To use a golf analogy, it’s a first great swing that can get your ball on the green rather than in the woods. This article is about how to determine your ideal starting composting recipe.

Step One is to understand the ingredients, i.e., the feedstocks. Feedstocks can vary greatly even when they seem similar. Residential food waste with food prep waste and leftovers is different from front-of-house cafeteria food waste with single-use compostable paper plates and napkins. Cow manure from one dairy may be very different from another one depending on how the manure is collected (flushing systems or scrapers), the age of the cows, or the length of their stay. It is always important to see and understand the feedstocks yourself ahead of time — and how they may change throughout the seasons — to help adjust the recipe as needed.

Feedstock Characteristics

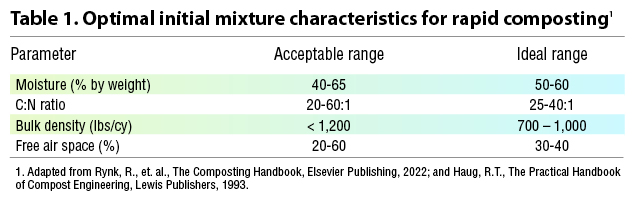

Understanding your feedstocks also requires understanding their characteristics: carbon-to-nitrogen (C:N) ratio, moisture, bulk density (BD), pH, metals, soluble salts, phosphorus, organic matter, volatile solids, ash, nutrients, and others. For simplicity, this article focuses on the three feedstock characteristics that can have the highest impact on your recipe: C:N, moisture, and BD. A fourth characteristic to evaluate is free air space (FAS), which is specific to the mixture only and not the feedstocks themselves. These four characteristics are used in the hands-on field activity during the Compost Research and Education Foundation’s Compost Operations Training Course (CREF COTC), and The Composting Handbook considers moisture and C:N the parameters of greatest concern to the process.

Ground yard waste with a 60:1 C:N ratio is on the high side. Adding a feedstock like food waste with a lower C:N ratio helps reach the starting target C:N ratio of 25-40:1. Photo by Nora Goldstein

Let’s use a ground yard waste (GYW) feedstock as an example to illustrate these characteristics. C:N ratio is the relative amount of elemental carbon to elemental nitrogen. All feedstocks have C and N, even in small amounts. The C:N ratio target range for the ideal starting mixture is 25-40:1, meaning there are 25 to 40 parts of carbon for every one part of nitrogen. So, if the GYW has a 60:1 C:N ratio, it means the ratio is on the high side and we need another feedstock with a lower C:N ratio to reach the target range.

Moisture is the amount of water in the feedstock and is expressed in percentage by weight relative to the dry part of the feedstock. The moisture target range for the ideal starting mixture is 40% to 65%, meaning the mixture is 40% to 65% water and 35% to 60% dry matter. Even though yard waste in general looks dry at 30% moisture, much of its moisture is hidden inside the cell walls. If our GYW has a moisture content of 35%, we will need another feedstock with higher moisture to reach the target range, or we can add liquid waste or water.

Bulk density of a feedstock is its weight divided by the volume it occupies. Image courtesy LSU College of Agriculture

Bulk Density (BD) of a feedstock is its weight divided by the volume it occupies. Imagine two 5-gallon buckets; one is filled with manure weighing 40 lbs and the other one is filled with GYW weighing 15 lbs. The one with manure will have a higher BD because, even though the manure and the GYW are both occupying the same volumetric space (5 gallons), the manure weighs much more than the GYW which is dry and has a lot of spaces in between the woody particles. The BD target range for the ideal starting mixture is 800 to 1,000 lbs/cy. In this example, our GYW is 600 pounds per cubic yard (lbs/cy) and the manure is 1,600 lbs/cy, meaning that the heavier manure will help balance the lighter GYW.

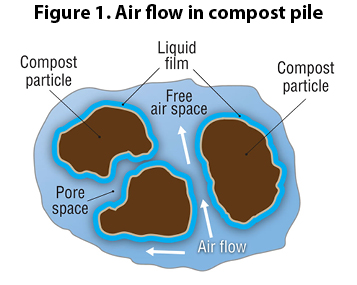

Lastly, Free Air Space (FAS) represents the voids in the mixture taken up by the air in between all of the structure of the composting mixture (Figure 1). It does not include the solid materials or the moisture around the materials. The higher the FAS, the easier it will be for air to move through the mixture, however it shouldn’t be too high because it would let too much air escape and not allow the heat to be retained. The FAS target range for the ideal starting mixture is 30% to 40%. If the mixture is out of range, you may need to look into feedstocks with different particle size distributions to balance it.

Lastly, Free Air Space (FAS) represents the voids in the mixture taken up by the air in between all of the structure of the composting mixture (Figure 1). It does not include the solid materials or the moisture around the materials. The higher the FAS, the easier it will be for air to move through the mixture, however it shouldn’t be too high because it would let too much air escape and not allow the heat to be retained. The FAS target range for the ideal starting mixture is 30% to 40%. If the mixture is out of range, you may need to look into feedstocks with different particle size distributions to balance it.

Table 1 summarizes optimal initial mixture characteristics. I recommend sending samples to a laboratory to obtain the values for C:N ratio and moisture — they could also provide BD. However, you can measure BD and FAS in the field using a 5-gallon bucket and a hand scale (instructions can be found in The Composting Handbook and NYC Master Composter Manual). If you do not have any data, you can use values from feedstock databases. Because these values are not specific to your feedstocks, you may have to iterate more in the field.

Calculating Feedstock Amounts

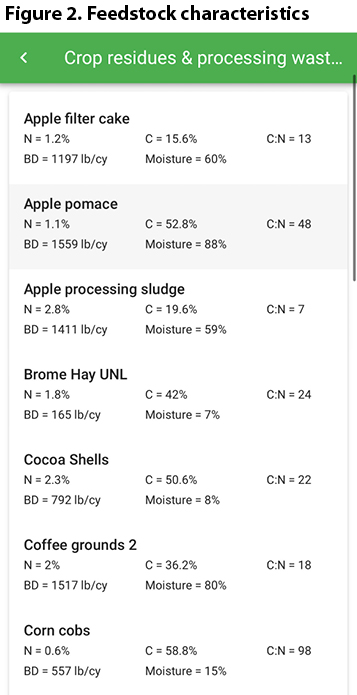

Once you have the values of the characteristics, you can calculate the feedstock amounts that will make up your ideal starting mixture recipe. The Composting Handbook and Cornell University show equations to calculate a balanced initial mixture. Performing these calculations for multiple feedstocks by hand can be time-consuming and challenging. This is when the time-saving calculators, such as the CompostCalc app, come in. This app is a free online calculator based on an excel calculator originally developed by Andy Bary and Craig Cogger with Washington State University-Puyallup and later upgraded by Cary Oshins and myself while teaching the CREF COTC. CompostCalc’s database is mostly drawn from the On Farm Composting Handbook (Rynk, 1992), Cornell University compost mixture recipe calculator, and CREF COTC.

Once you have the values of the characteristics, you can calculate the feedstock amounts that will make up your ideal starting mixture recipe. The Composting Handbook and Cornell University show equations to calculate a balanced initial mixture. Performing these calculations for multiple feedstocks by hand can be time-consuming and challenging. This is when the time-saving calculators, such as the CompostCalc app, come in. This app is a free online calculator based on an excel calculator originally developed by Andy Bary and Craig Cogger with Washington State University-Puyallup and later upgraded by Cary Oshins and myself while teaching the CREF COTC. CompostCalc’s database is mostly drawn from the On Farm Composting Handbook (Rynk, 1992), Cornell University compost mixture recipe calculator, and CREF COTC.

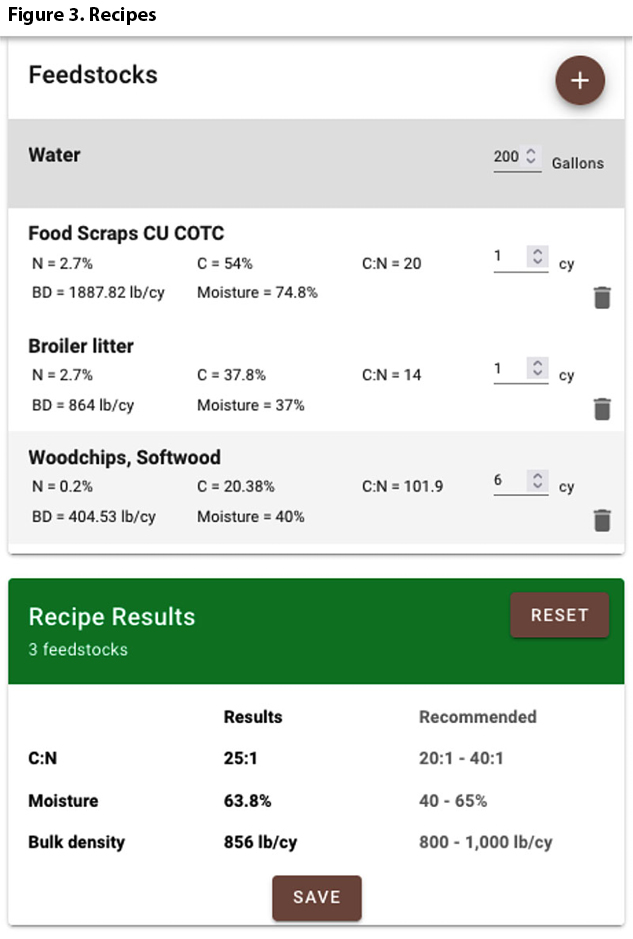

To use the CompostCalc, first, enter your own feedstocks or select from the database (Figure 2). Then, adjust the feedstock ratios and water until you reach the recommended target ranges for the characteristics discussed above. The recipe results are calculated automatically whenever you adjust a value for gallons or “cy” (cubic yard). Once you reach the recommended target ranges, you have found your ideal starting recipe! Figure 3 shows the results for a more complex example using three feedstocks and additional water.

Field Testing The Recipe

Field Testing The Recipe

Now that you have your ideal starting mixture recipe, it is time to test it in the field. First, make a small test batch and measure the mixture’s moisture, BD, and FAS. Ensure that it is within your ideal starting range and then make changes as necessary. For example, if the mixture is too wet, add more dry material, and if it is too dry, add more of the feedstock with a higher moisture or simply add more liquid. If the bulk density is too low, add more of the heavier material or you may need to chop your material smaller because it may be too coarse. Make sure to write down any changes. Anticipate changing the recipe because field conditions may have changed from the time you took measurements.

After refining your recipe, test it by making a large batch and monitoring its performance over a few weeks. Modify it as necessary until you land at your optimal recipe (be sure to write it down). Remember that you may have to change your recipe with the seasons and that as decomposition takes place, the starting values will change in your final product (moisture and C:N ratio should decrease and BD increase). Calculators exist to help you narrow your starting point so that you do not have to make as many changes at the start and get you producing compost faster.

Summary

The following six steps summarize how to create your ideal starting composting recipe:

- Understand your feedstocks and their characteristics.

- Get data for your feedstocks.

- Use a calculator to speed up your starting point.

- In the field, test a small batch with your starting recipe and modify as needed.

- Build a compost pile to test the recipe, monitor, and iterate as needed.

- Keep in mind seasonal changes and modify recipe as needed.

Jorge Montezuma, P.E., is Principal at Wanu Organics near Raleigh, NC, a consulting firm assisting organizations to develop and improve composting and organic waste recycling projects. He has over a decade of organics experience working in the public and private sectors and since 2013 has been a key instructor in the NC CREF Composting Operations Training Course. In 2019 and with the help of his brother, Jorge developed CompostCalc to make calculations simpler and faster.